Intelligent automobile maintenance data acquisition system

A technology of acquisition system and data acquisition module, applied in general control system, control/regulation system, registration/indication of vehicle operation, etc. The effect of improving core competitiveness, reducing procurement costs and being easy to manage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

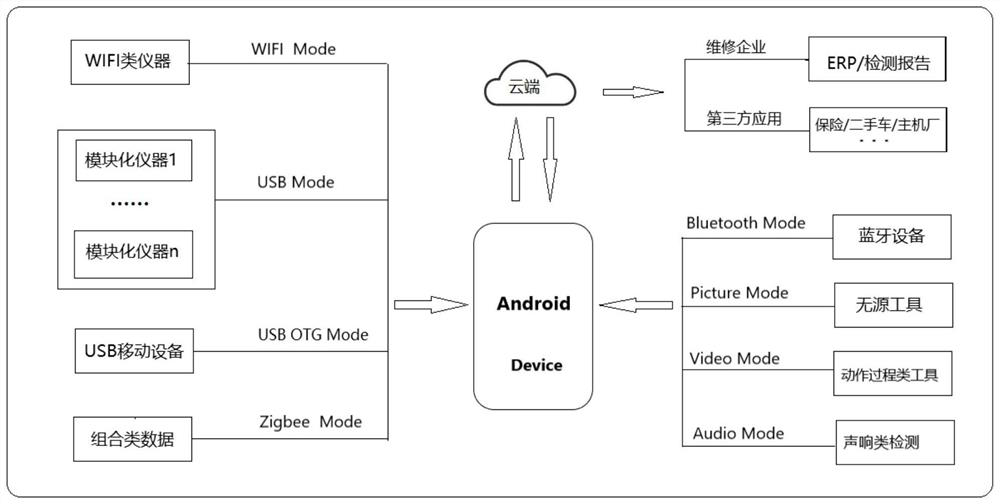

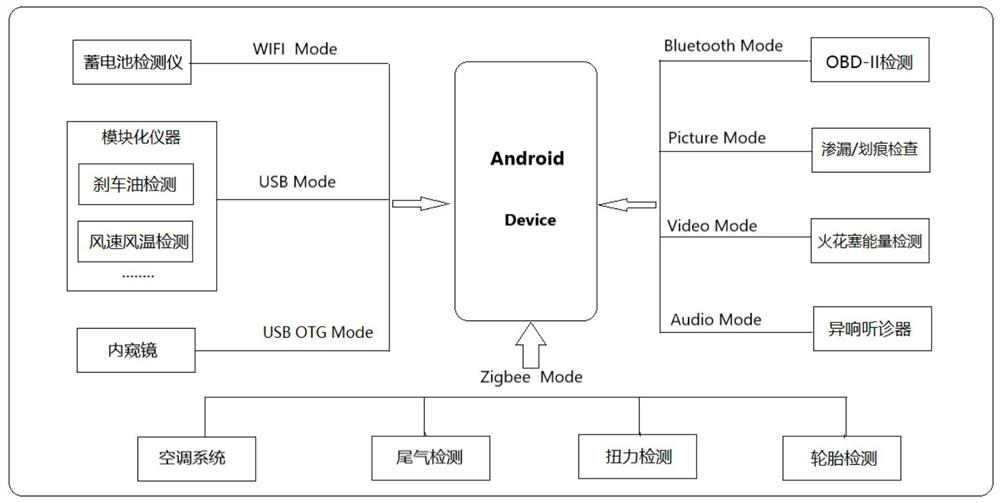

[0043] Such as Figure 1 to Figure 2 As shown, the automobile maintenance data intelligent acquisition system includes an Android device and a peripheral data acquisition module, the peripheral data acquisition module adopts an embedded structure to directly connect with the Android device, and the peripheral data acquisition module is connected to the Android device in a USB mode Exchanging data; the peripheral data acquisition module is used for signal acquisition, signal conditioning, and USB conversion; the Android device is used for 5V power supply, data display, data processing, and data application;

[0044] The peripheral data acquisition module can automatically collect data, automatically store and automatically upload cloud database, including brake oil detection module, battery detection module, wind speed and temperature detection module, sonar detection module, illuminance detection module, wheel data collection module, USB Endoscope module, OBD module;

[0045]...

Embodiment 2

[0055] Such as Figure 1 to Figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the signal acquisition of the peripheral data acquisition module is realized by a sensor, and the corresponding sensor device is selected according to the acquisition object, and the module corresponding to the sensor interface and the peripheral data acquisition module The signal conditioning unit and the USB conversion unit of the instrument are designed on the same circuit board; the signal conditioning of the peripheral data acquisition module passes through each module inside the instrument according to the characteristics of various sensor signals, and the signal conversion is realized by different signal conditioning modules, including :

[0056] Current signal conditioning, the commonly used sensor current signals of 0-20mA or 4-20mA are adjusted to a voltage signal of 0-5V, which is supplied to the input port of the subsequent A / D converter;

[0057] Voltage...

Embodiment 3

[0063] Such as Figure 1 to Figure 2 As shown, the peripheral data acquisition module also includes a pH value detection module, a temperature and humidity detection module, a current detection module, a light transmission detection module, a coating thickness detection module, an infrared temperature detection module and a torque detection module;

[0064] The PH value detection module is used to quickly detect the pH of the antifreeze solution of the automobile engine, and the PH value detection module is embedded in the Android device, and transmits data through USB communication;

[0065] The temperature and humidity detection module is used to quickly measure the temperature and humidity around the vehicle and in the cab, the temperature and humidity detection module is embedded in the Android device, and transmits data through USB communication;

[0066] The current detection module is used to quickly measure the starting current, charging current, electrical appliance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com