Real-time prediction method for gas leakage influence range

A technology of real-time prediction and influence range, which is used in liquid/vacuum measurement for liquid tightness, fluid tightness test, measurement device, etc. The effect of judging and accurate emission source area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] A method for real-time prediction of the impact range of non-liquid leakage, including:

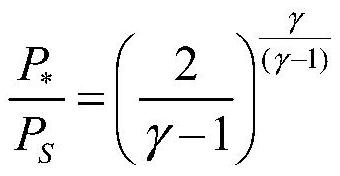

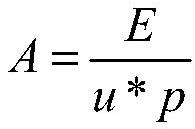

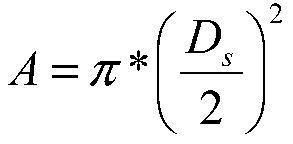

[0062] The first step is to obtain the non-liquid storage pressure, and calculate the pressure at the outlet of the non-liquid leakage according to the obtained non-liquid storage pressure, compare the obtained pressure at the non-liquid leakage outlet with the atmospheric pressure of the environment, and Judging the actual state of non-liquid leakage based on the comparison results;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com