Waste dry battery pretreatment recovery process and recovery treatment device

A technology for recycling and processing waste batteries, applied in the field of waste dry battery pretreatment recycling process and recycling and processing devices, can solve problems such as threats to the life safety of workers, equipment loss, battery explosion, etc., to improve metal recovery rate, improve efficiency, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

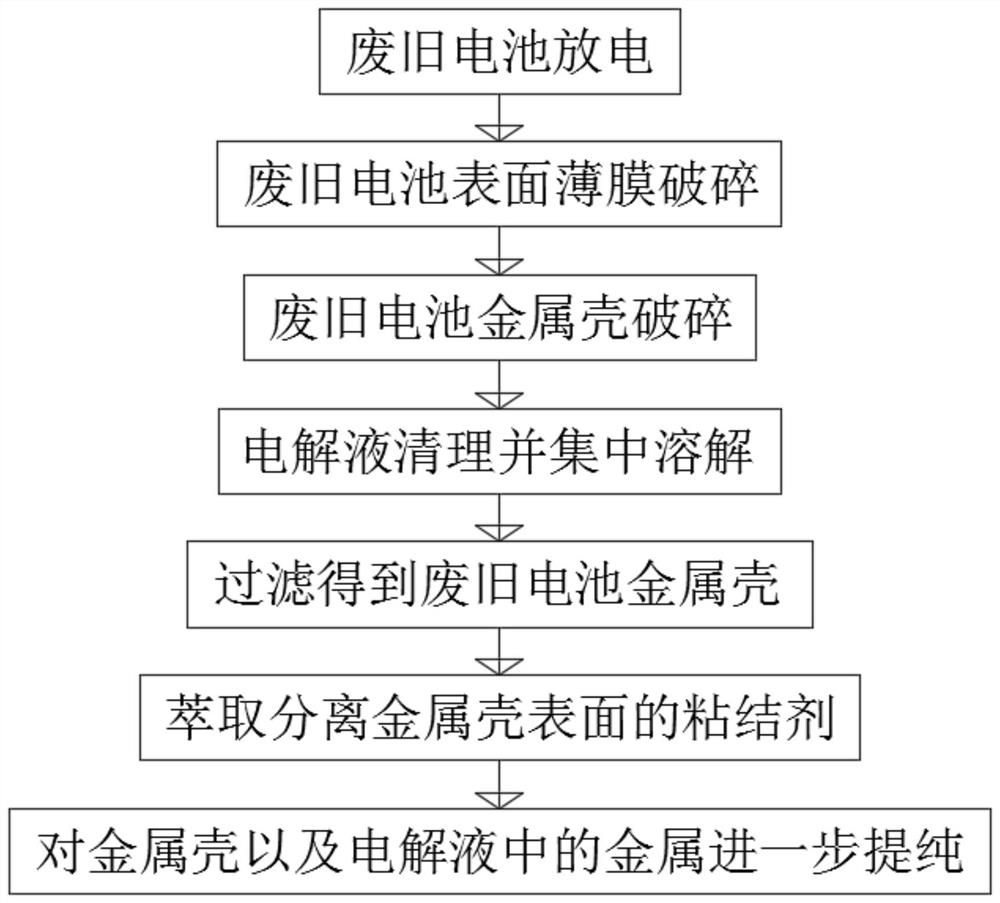

[0048] A kind of waste dry battery pretreatment recovery process and recovery treatment device, please refer to figure 1 , the waste dry battery pretreatment recycling process is:

[0049] Step 1. Release the remaining power of the used battery to prevent the subsequent dismantling of the battery from releasing huge heat, which has certain safety hazards;

[0050] Step 2, the film on the surface of the used battery is separated from the inner metal shell;

[0051] Step 3. Collect waste batteries with only metal shells for centralized crushing;

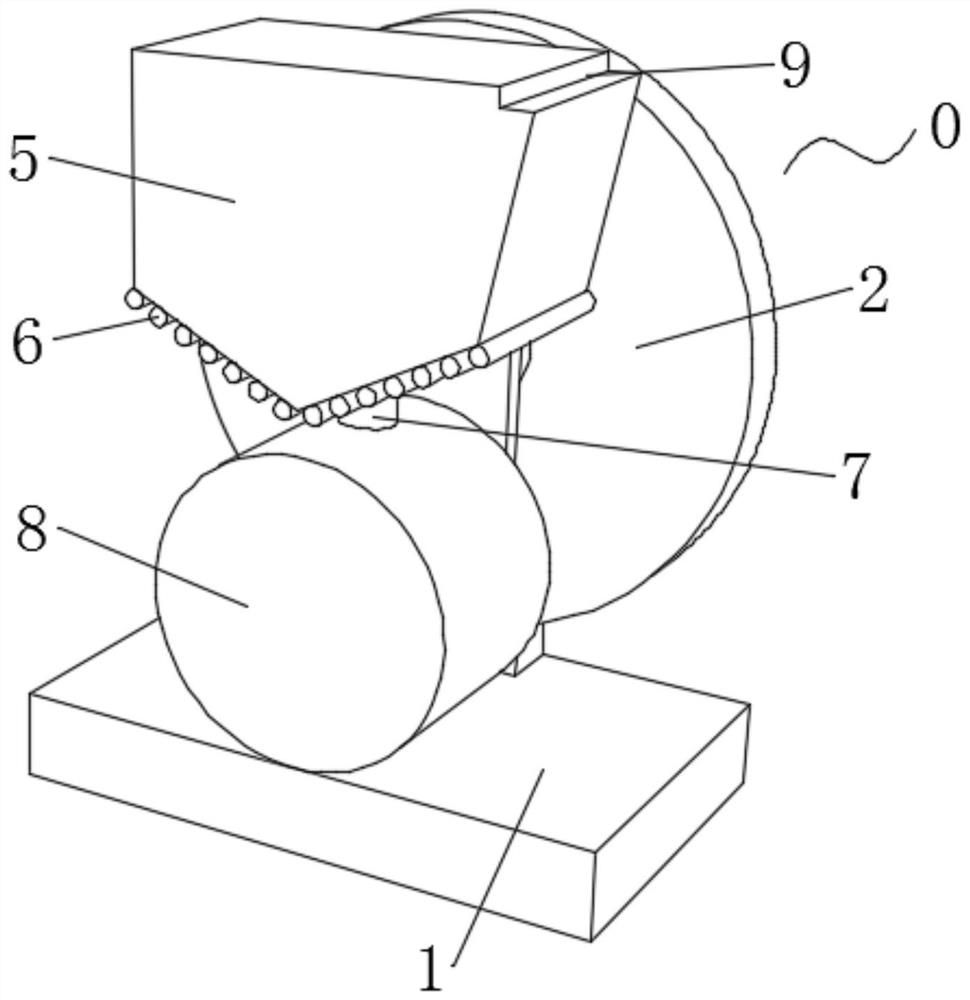

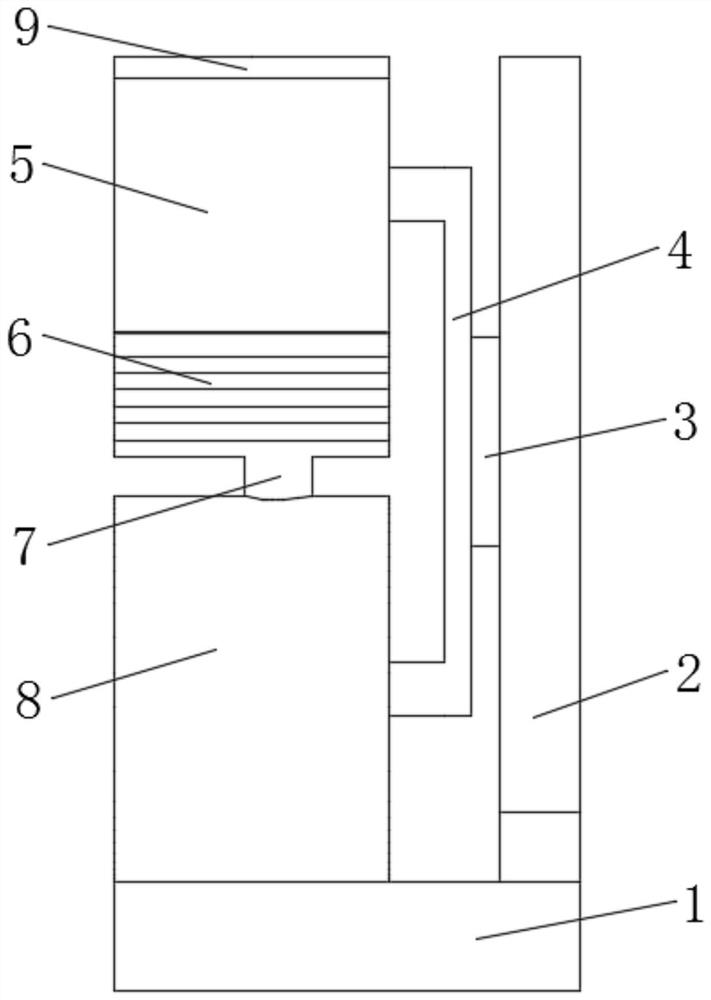

[0052] Step 4: Use the recovery device body 0 to cut and break the waste battery, and rinse the cut waste battery with the high-pressure water pipe 11 above the decomposition box 5, so that the electrolyte and washing liquid in the waste battery flow into the dissolution box 8;

[0053] Step 5. Collect and extract the adhesive on the surface of the broken waste battery shells left in the decomposition box 5 to prepare for the subsequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com