Granular material throwing device

A throwing device and granular technology, which is applied in fertilization devices, fertilizer distributors, applications, etc., can solve the problems of waste of raw materials, inability to accurately scatter particles, and limited scatter efficiency, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

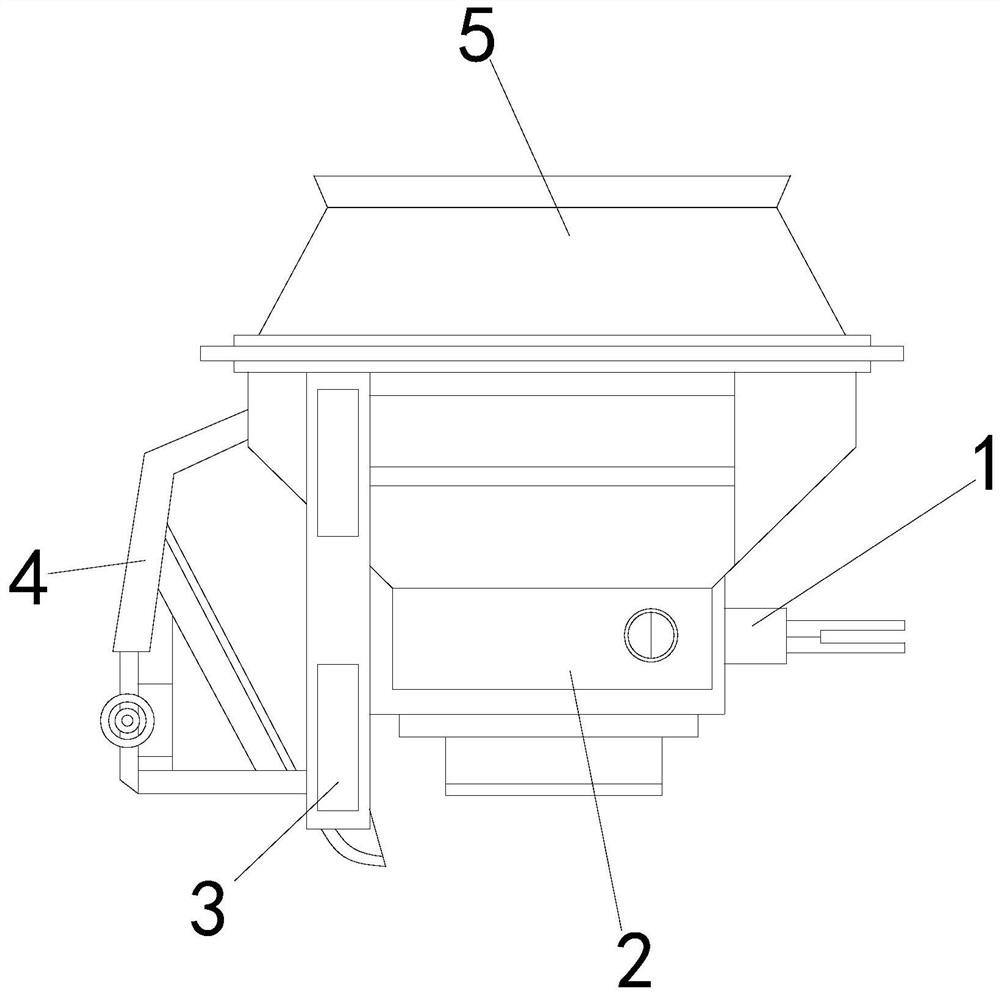

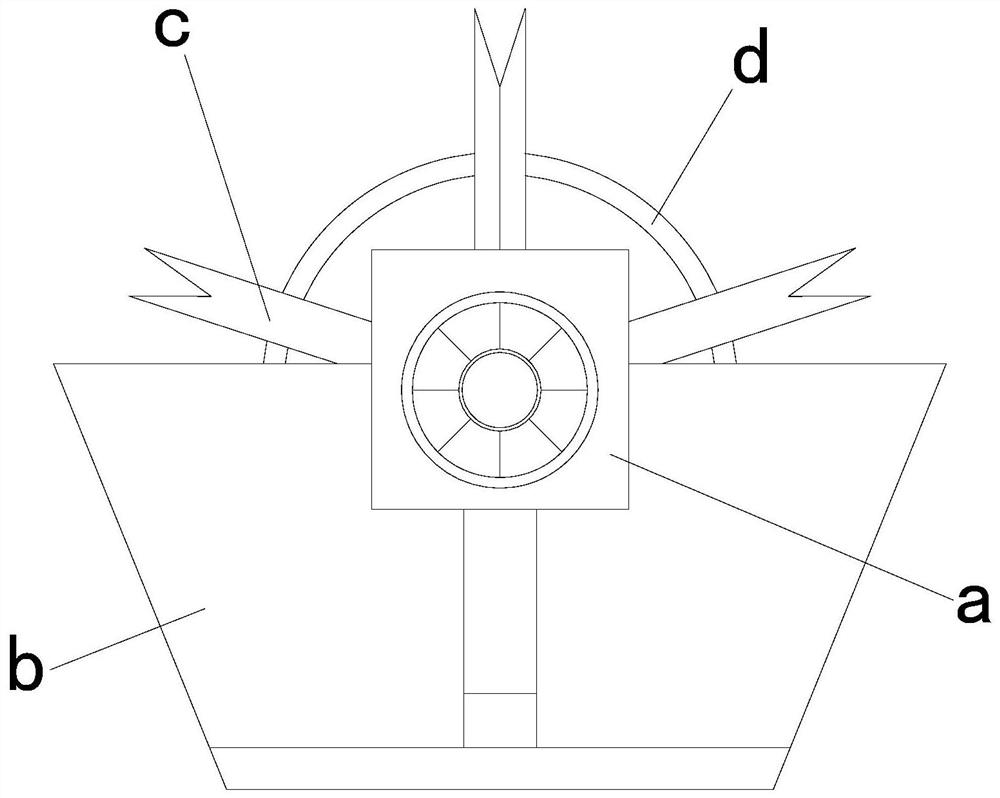

[0025] see Figure 1-Figure 2 , the present invention provides a technical solution for a granular material throwing device: its structure includes: a throwing body 1, a power device 2, a moving matching seat 3, a connecting frame 4, and a raw material bin 5, and the raw material bin 5 is installed on the power device 2 Above and locked with the power device 2, the right side of the power device 2 is provided with a throwing body 1, the throwing body 1 is movably connected with the power device 2, and the left end of the power device 2 is provided with a moving matching seat 3, and the moving The matching seat 3 is locked with the power device 2, and the left side of the moving matching seat 3 is provided with a connecting frame 4, and the connecting frame 4 is threadedly connected with the moving matching seat 3, and the throwing machine body 1 includes a movable leaking cylinder device a , baffle plate b, throwing frame c, fixed frame d, the movable leakage tube device a is ...

no. 2 example

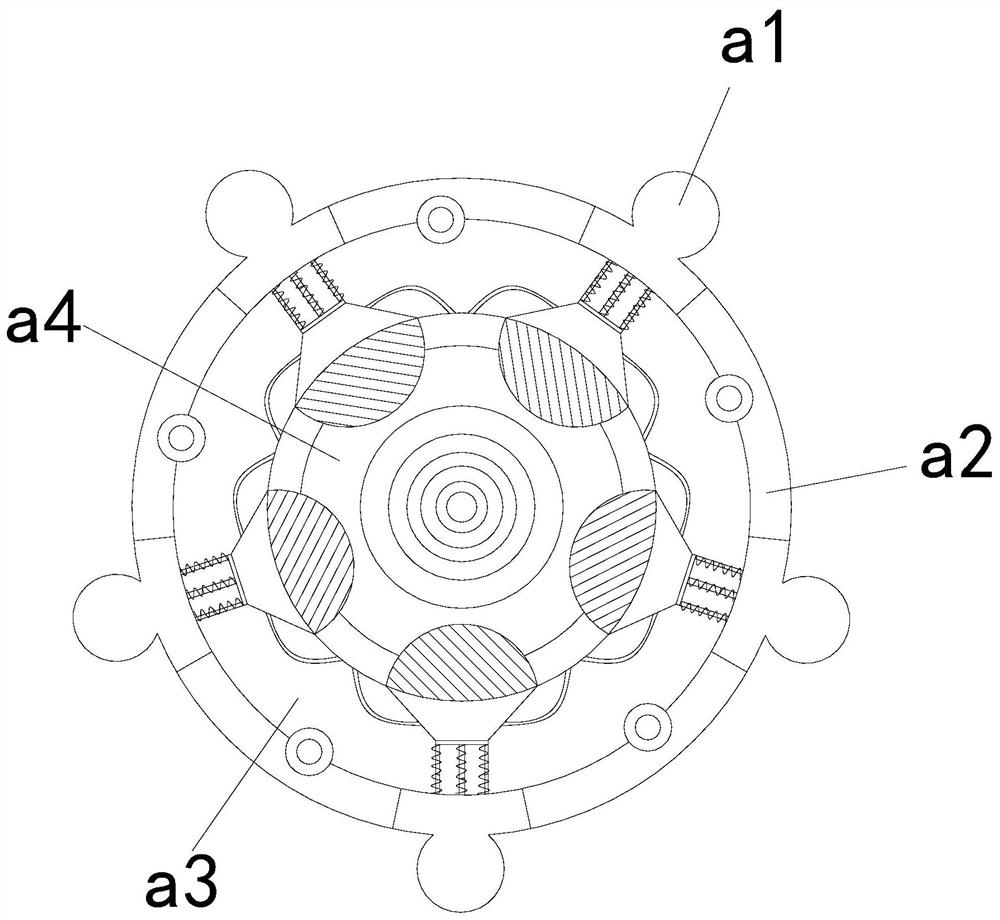

[0028] see Figure 3-Figure 5 , the present invention provides a technical solution for a granular material throwing device: its structure includes: the movable funnel device a includes a self-opening block device a1, an assembly groove a2, a connecting funnel a3, and a feeding groove pipe a4; A self-opening block device a1 is provided on the periphery of the trough pipe a4, and the self-opening block device a1 is closely matched with the feeding trough pipe a4, and a connecting funnel a3 is provided under the self-opening block device a1 and is connected to the connecting funnel. a3 is fastened, and the outside of the connecting funnel a3 is provided with an assembly groove a2.

[0029] The self-opening block device a1 includes a connection spring a11, a counterweight a12, a reset rope a13, and a groove stopper a14. The counterweight a12 is installed at the end of the connection spring a11 and is fastened with the connection spring a11. The inner side of the connection sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com