Mask laminated composite filter element material structure and mask

A composite filtration and lamination technology, applied in the field of masks, can solve the problems of heavy mask moisture, affecting wearing comfort and service life, bacterial growth, etc., and achieve the effect of improving the breathing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

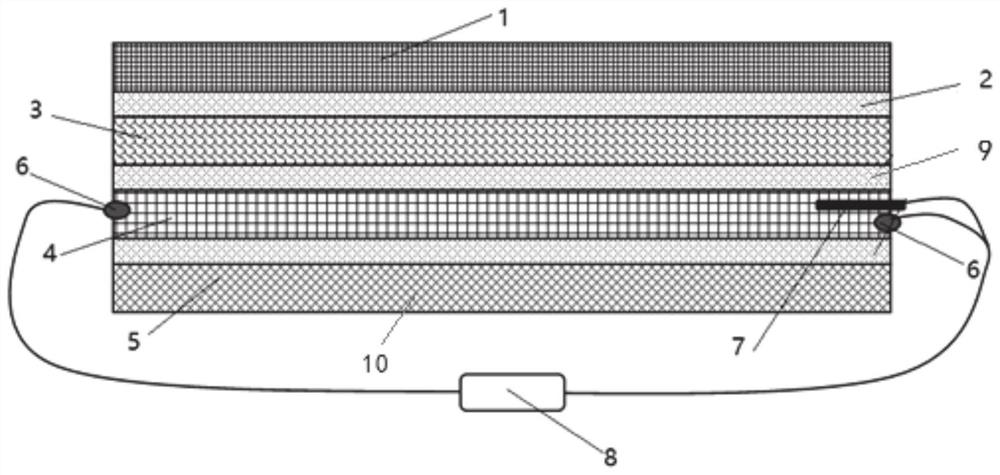

[0050] A laminated composite filter core material structure for a mask, comprising: a spunbonded nonwoven fabric waterproof layer 1, a first spunbonded nonwoven fabric insulation barrier layer 2, an activated carbon fiber adsorption layer 3, a second spunbonded nonwoven fabric insulation layer The barrier layer 9, the carbon fiber fabric electric heating layer 4, the third spun-bonded non-woven fabric insulation barrier layer 10, and the melt-blown non-woven fabric skin-friendly layer 5 are stacked to form seven layers. Wherein, the connection terminal 6 and the temperature sensor 7 are embedded in the carbon fiber fabric electric heating layer 4, and the temperature of the whole laminated structure is adjusted and heated through the connection of the battery 8 for power supply.

[0051] The material of the spun-bonded non-woven fabric waterproof layer 1 is polyethylene with a gram weight of 15g / m 2 , 0.7 grams per piece;

[0052] The activated carbon fiber adsorption layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com