Antibacterial acarus-killing magnetic comprehensive functional mattress

A magnetic and mattress technology, applied in the field of magnetic therapy mattresses, can solve the problems of affecting the use effect of mattresses, poor antibacterial and mite removal effects of mattresses, etc., and achieve the goal of improving moisture absorption and perspiration performance, comfortable sleeping environment, and healthy sleeping environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

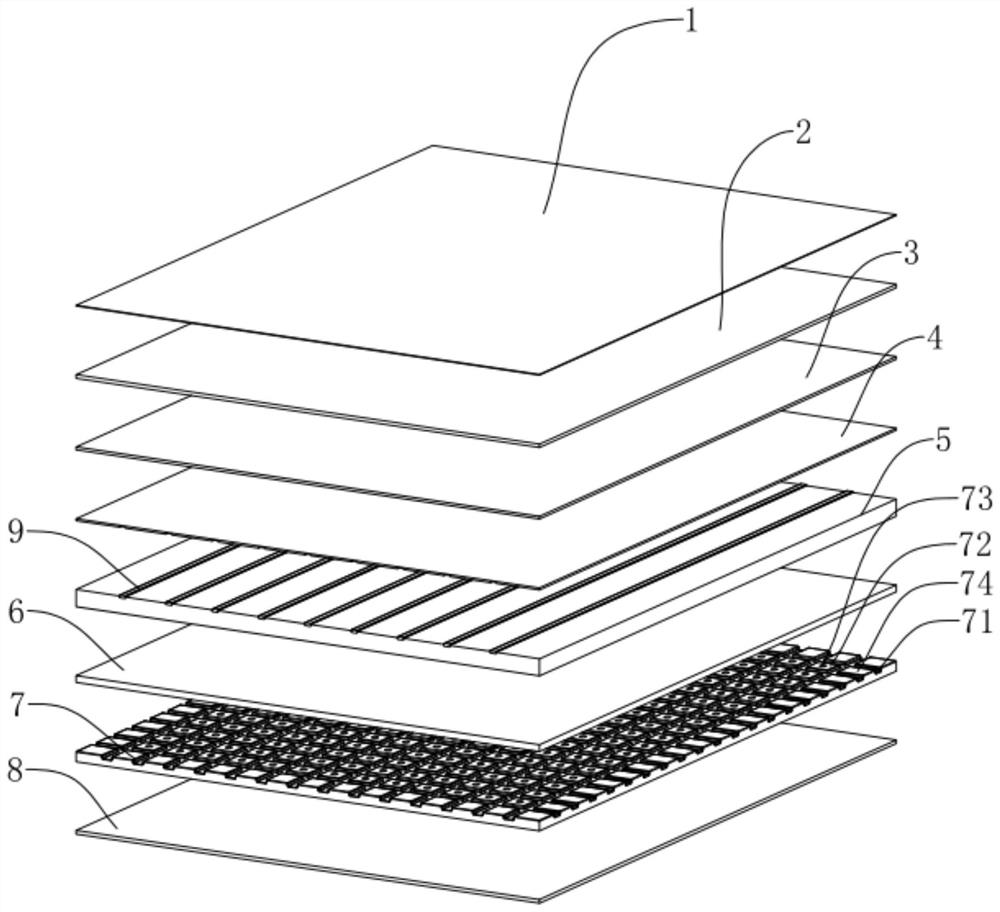

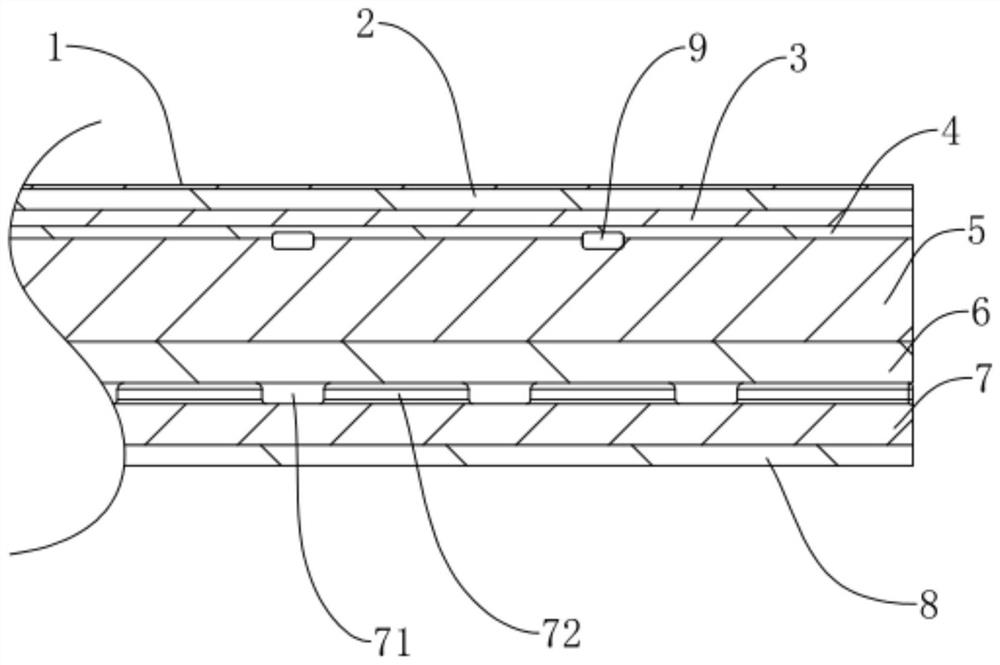

[0049] Such as figure 1 As shown, an antibacterial and mite-removing magnetic comprehensive functional mattress includes a jacquard fabric layer 1, a functional fiber layer 2, a cotton layer 3, a three-dimensional mesh layer 4, a latex layer 5 and a bridging layer 7 sequentially connected from top to bottom . The jacquard fabric layer 1 comprises bamboo fiber and polyester in a ratio of 1:2 by weight; Formed by the advanced manufacturing method, it has the characteristics of softness and skin-friendliness, and is comfortable to use; the functional fiber layer 2 has the characteristics of releasing negative ions and far-infrared rays, thereby achieving the purpose of antibacterial and anti-mite. A plurality of flexible broadband magnetic strips 9 arranged at equal intervals are arranged on the upper side of the latex layer 5 . The flexible broadband magnetic strip 9 generates a constant magnetic field of 180mT on the magnetic therapy health care mattress, and then performs ma...

Embodiment 2

[0063] The difference between the second embodiment and the first embodiment is that the jacquard fabric layer 1 in the second embodiment includes bamboo fiber and polyester in a weight ratio of 1:2.

[0064] At the same time, the manufacturing process of the modified porous sponge comprises the following steps:

[0065] Step 1. Take 90 parts of polyether and 8 parts of nano-zinc oxide by weight and add them into the closed mixer. Nitrogen gas is introduced into the mixer. The pressure of the mixer is controlled at 1atm, and the temperature is 70°C. material;

[0066] Step 2. Naturally cool the mixed material to room temperature and introduce it into the foaming machine, and add 0.25 parts of silver ammonia and 0.15 parts of silicone oil into the foaming machine, and control the stirring speed of the foaming machine at room temperature to 3000r / min. Foaming time is 15min, obtains foaming material;

[0067] Step 3. Spray the foaming material into the mold cavity through the n...

Embodiment 3

[0074] The difference between the third embodiment and the first embodiment is that the jacquard fabric layer 1 in the third embodiment includes bamboo fiber and polyester in a weight ratio of 1:2.

[0075] At the same time, the manufacturing process of the modified porous sponge comprises the following steps:

[0076] Step 1. Take 100 parts of polyether and 10 parts of nano-zinc oxide in parts by weight and add them into the closed mixer. Nitrogen gas is introduced into the mixer. The pressure of the mixer is controlled at 1 atm and the temperature is 80 ° C. material;

[0077] Step 2. Naturally cool the mixed material to room temperature and introduce it into the foaming machine, and add 0.3 parts of silver ammonia and 0.2 parts of silicone oil into the foaming machine, and control the stirring speed of the foaming machine at room temperature to 3000r / min. Foaming time is 15min, obtains foaming material;

[0078] Step 3. Spray the foaming material into the mold cavity thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com