Special manipulator for sand and gravel crushing

A technology of manipulators and gravel, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of cumbersome operation of rotation and multi-angle extraction work, complex manipulator structure, etc., achieve good grasping effect, wide application range, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Further detailed explanation through specific implementation mode below:

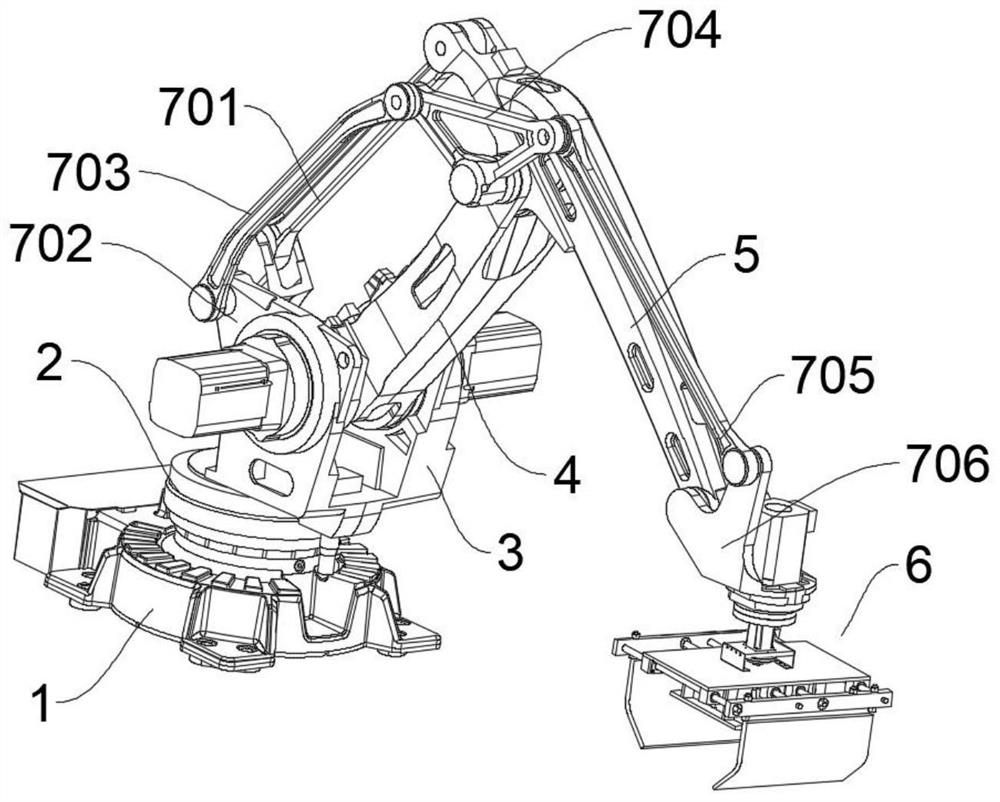

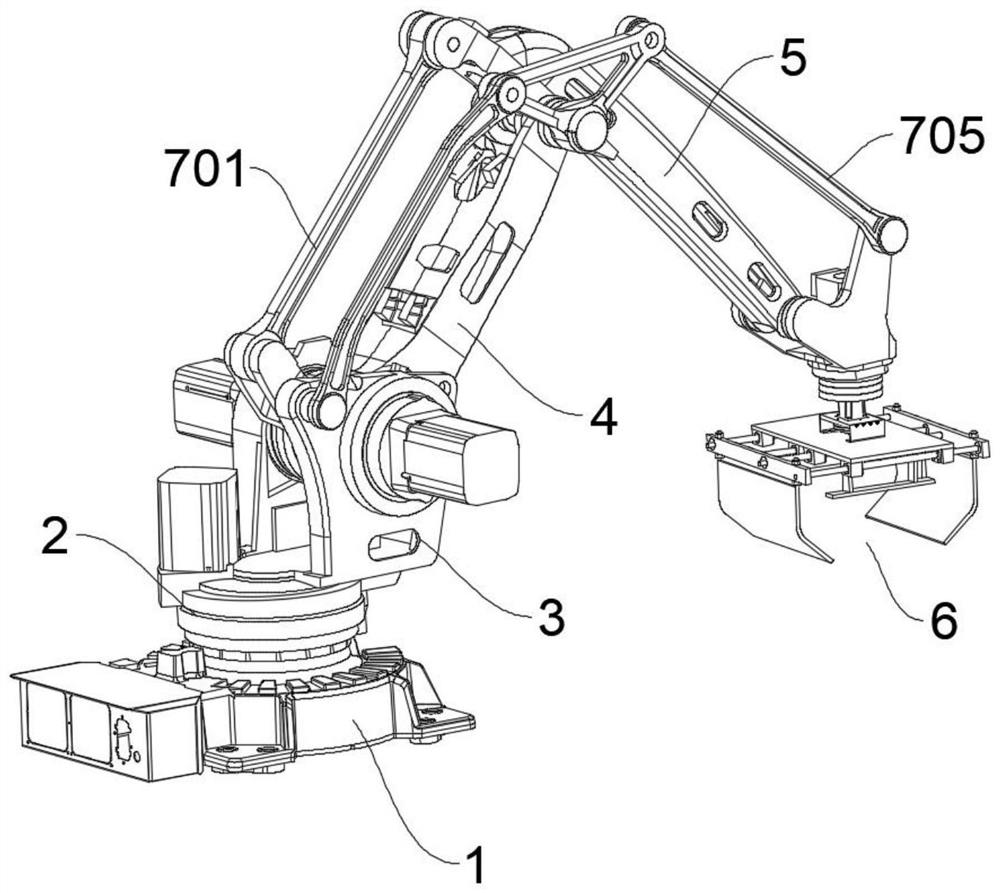

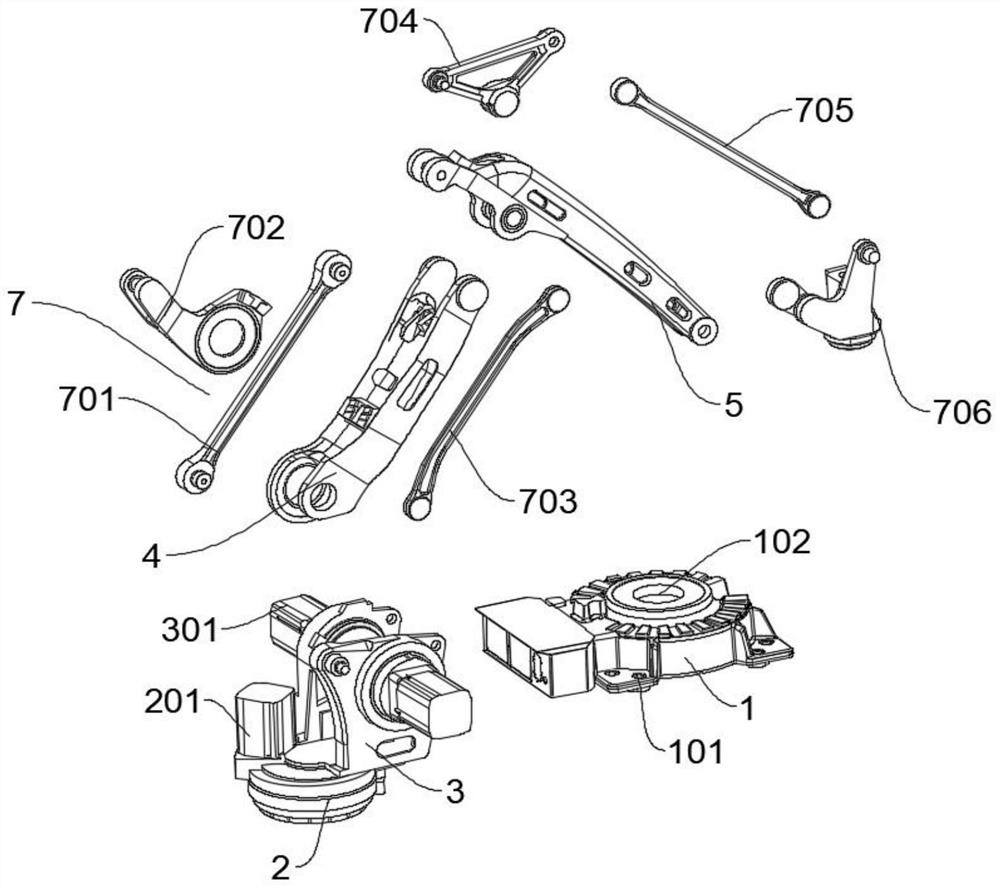

[0040] Such as Figures 1 to 9 As shown, the special manipulator for sand and gravel crushing includes a rotating assembly and a grabbing assembly 6, and the rotating assembly includes a rotating part and a rotating part. The rotating part includes a mounting base 1, a rotating base 2 and a wrist. There is a first mounting hole 102 in the middle of the mounting base 1. The bottom of the rotating base 2 is installed in the first mounting hole 102, and the rotating base 2 is connected with the first mounting hole. The center line of 102 is connected to the mounting base 1 in a way that the rotation center rotates. The rotating base 2 is connected to the first drive motor 201. The first driving motor 201 drives the rotating base 2 to rotate relative to the mounting base 1. The wrist is fixed on the rotating base. 2, the wrist part includes a U-shaped piece 3, the bottom of the U-shaped piece 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com