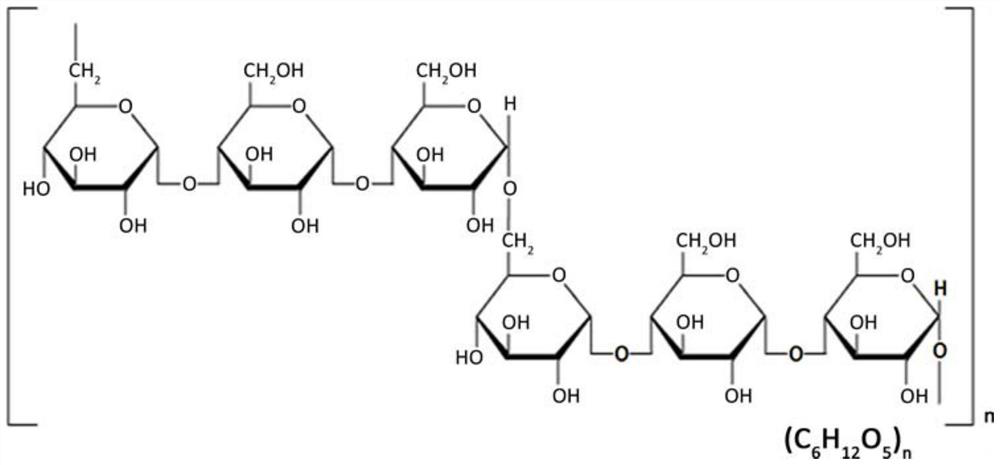

High-temperature-resistant crosslinked polysaccharide polymer for drilling fluid and preparation method thereof

The technology of polysaccharide polymer and cross-linked polysaccharide is applied in the field of high-temperature resistant cross-linked polysaccharide polymer for drilling fluid and its preparation. The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

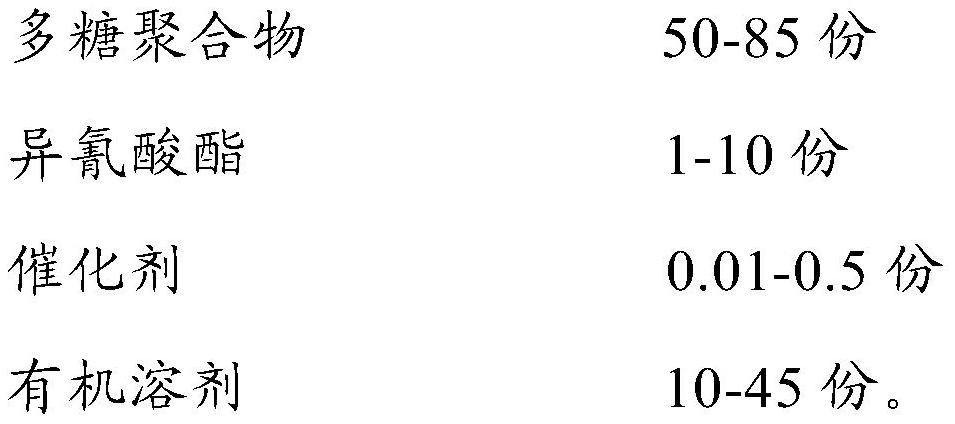

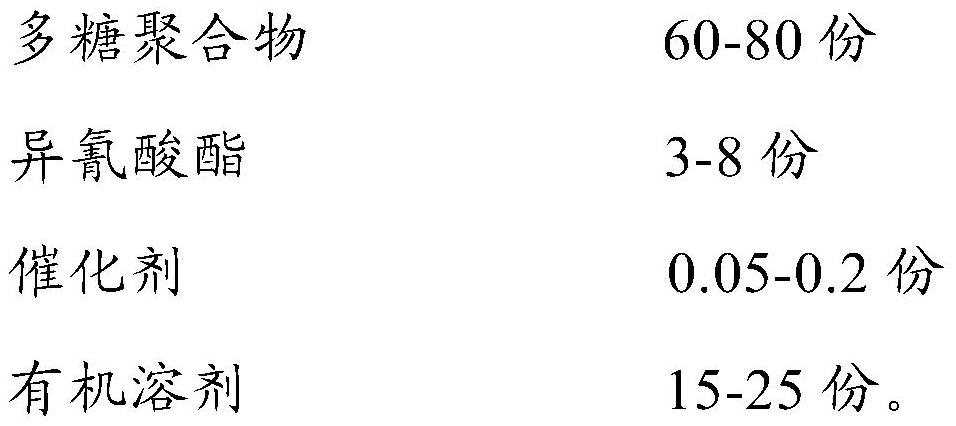

Embodiment 1

[0029] This embodiment provides a high temperature resistant cross-linked polysaccharide polymer for drilling fluid, including the following raw materials in parts by weight: polysaccharide polymer (pregelatinized starch, Hebei Hengju Chemical Industry) 68kg, isocyanate (TDI-80, containing 80% by mass The mixture of 2,4-toluene diisocyanate and 20 mass percent 2,6-toluene diisocyanate, Cangzhou Dahua) 2.2kg, catalyst (organotin, T12, American Gas Chemical) 0.01kg, Organic solvent (butyl acetate, Shandong Nuoer Chemical Industry) 29.79kg.

[0030] Vacuum-dry the polysaccharide polymer in advance for later use; add 68kg of dried polysaccharide polymer and 29.79kg of organic solvent into the reaction kettle, heat up to 50°C, and stir for 1.5 hours; slowly add 2.2kg of isocyanate dropwise, at 90°C 0.01 kg of catalyst was added, and the reaction was continued for 2 hours; the product was distilled to recover the organic solvent, and then dried, pulverized, and passed through a 60-m...

Embodiment 2

[0032] This embodiment provides a high temperature resistant cross-linked polysaccharide polymer for drilling fluid, including the following raw materials in parts by weight: polysaccharide polymer 1 (pregelatinized starch, Hebei Hengju Chemical Industry) 50kg, polysaccharide polymer 2 (carboxymethyl starch , Shandong Weifang Lite) 34.8kg, isocyanate (MDI-50, 50% by mass of 2,4-diphenylmethane diisocyanate and 50% by mass of 4,4'-diphenylmethane diisocyanate Mixture of isocyanate, Wanhua Chemical) 5kg, catalyst (organic zinc, Bicat Z, Shanghai Deyin Chemical) 0.2kg, organic solvent (tetrahydrofuran, Shandong Nuoer Chemical) 10kg.

[0033] Vacuum-dry polysaccharide polymer 1 and polysaccharide polymer 2 in advance for later use; add 50kg of dried polysaccharide polymer 1, 34.8kg of polysaccharide polymer 2, and 10kg of organic solvent into the reaction kettle, heat up to 50°C, and stir 0.5 hours; slowly add 5kg of isocyanate dropwise, and react at 80°C with high-speed stirring ...

Embodiment 3

[0035] This embodiment provides a high temperature resistant cross-linked polysaccharide polymer for drilling fluid, including the following raw materials in parts by weight: polysaccharide polymer 1 (pregelatinized starch, Hebei Hengju Chemical Industry Co., Ltd.) 50 kg, polysaccharide polymer 2 (carboxymethyl fiber element, LV-CMC) 25kg, isocyanate (IPDI, isophorone diisocyanate, Covestro) 7kg, catalyst (organic bismuth, Bicat8118, American leading chemical) 0.5kg, organic solvent (methyl ethyl ketone, Guangdong Blue Arrow Chemical) 17.5 kg.

[0036] Vacuum-dry polysaccharide polymer 1 and polysaccharide polymer 2 in advance for later use; add 50kg of dried polysaccharide polymer 1, 25kg of polysaccharide polymer 2, and 17.5kg of organic solvent into the reaction kettle, heat up to 40°C, and stir 2 hours; slowly add 7kg of isocyanate dropwise, and react at 60°C with high-speed stirring for 3 hours; add 0.5kg of catalyst, continue to stir and react for 1 hour; Mesh standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com