Three-axis angle adjustment tooling

A technology of axis angle and tooling, applied in the field of environmental testing, can solve the problems of high difficulty in multi-angle conversion tooling design, low use effect, limited use, single structure and function, etc., to optimize the replacement of test platforms, save resources, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

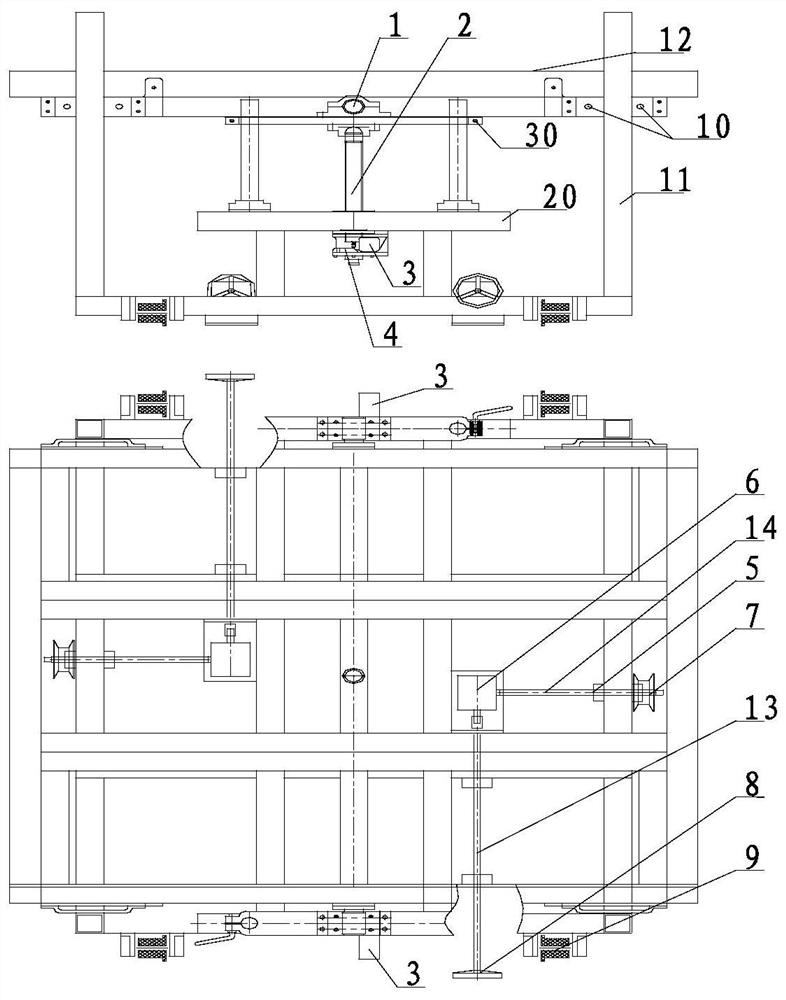

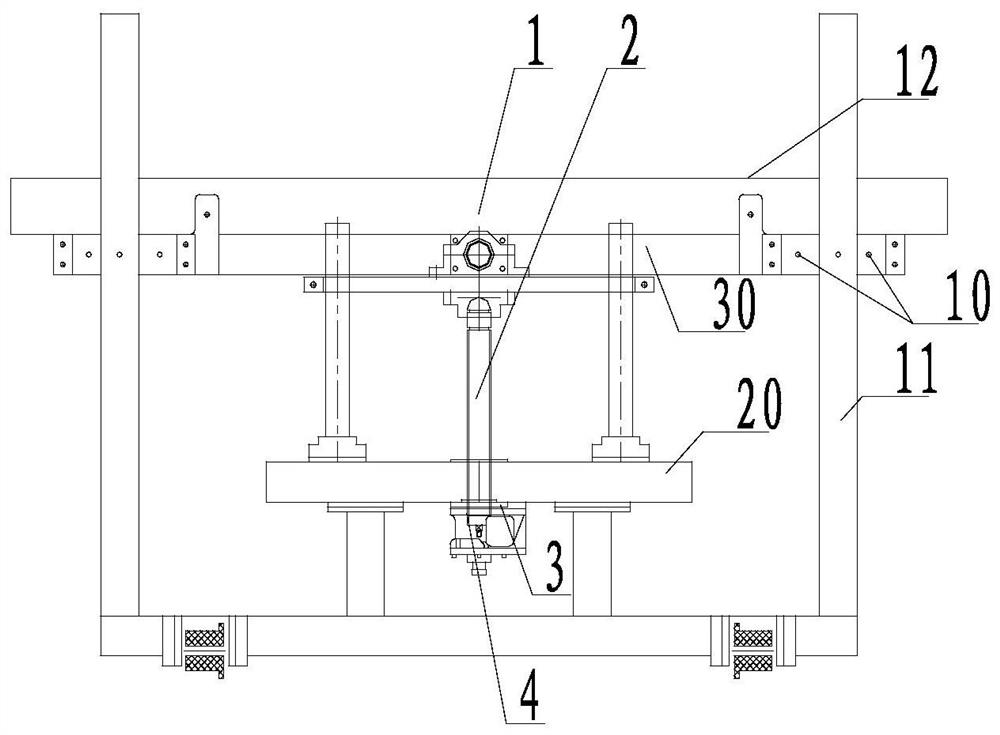

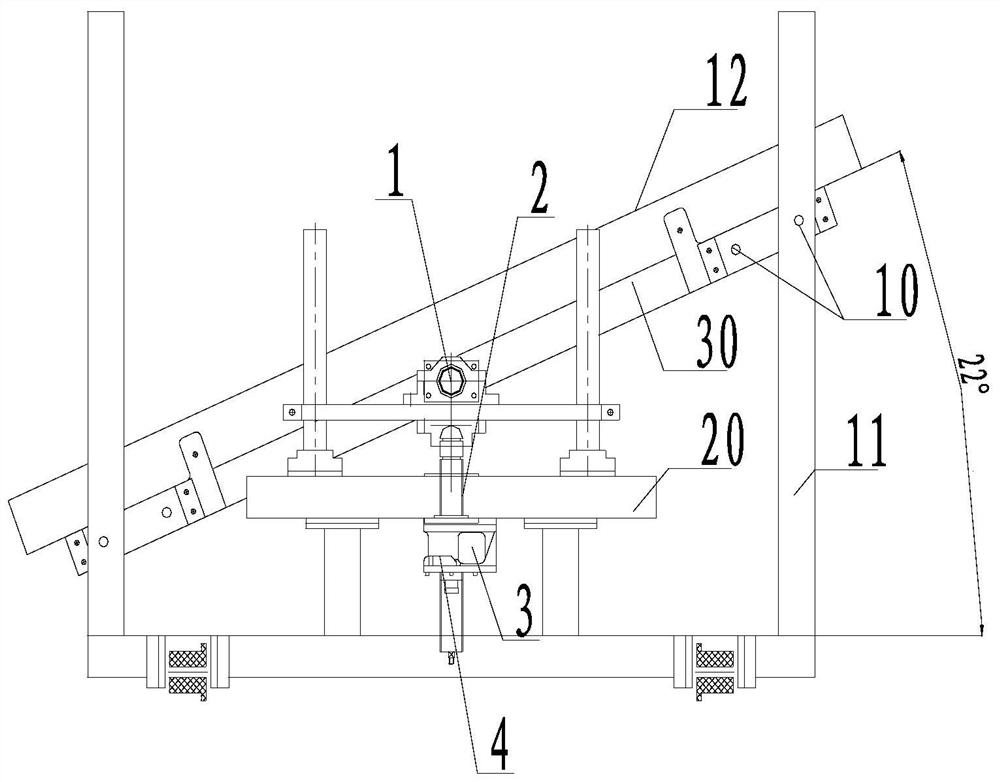

[0037] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] The three-axis angle adjustment tooling of the present invention includes: a rotating shaft (1), a lifting worm structure (2), a motor (3), a reducer (4), two sets of transmission systems, a guide wheel (9), and a positioning pin ( 10), the main frame (11), and the installation frame (12); the three-axis angle conversion function is realized in the environment of normal temperature and pressure. After the function is realized, the product is tested in a vacuum and low temperature environment. The main frame (11) mainly carries the product and The installation basis of other components, the rotating shaft (1) is installed on both sides of the installation frame (12), the lifting worm structure (2) is matched with the reducer (4), and the reducer (4) and the motor (3) are installed and fixed. The motor supplies power to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com