Optimal Displacement Control Method for Cantilevered Construction of Cable-Stayed Bridges

A control method and technology of cable-stayed bridges, applied in the field of transportation bridge and culvert engineering, can solve the problems of uniform effects, cumbersome work, low efficiency, etc., and achieve the effects of wide application range, ensuring traffic efficiency, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

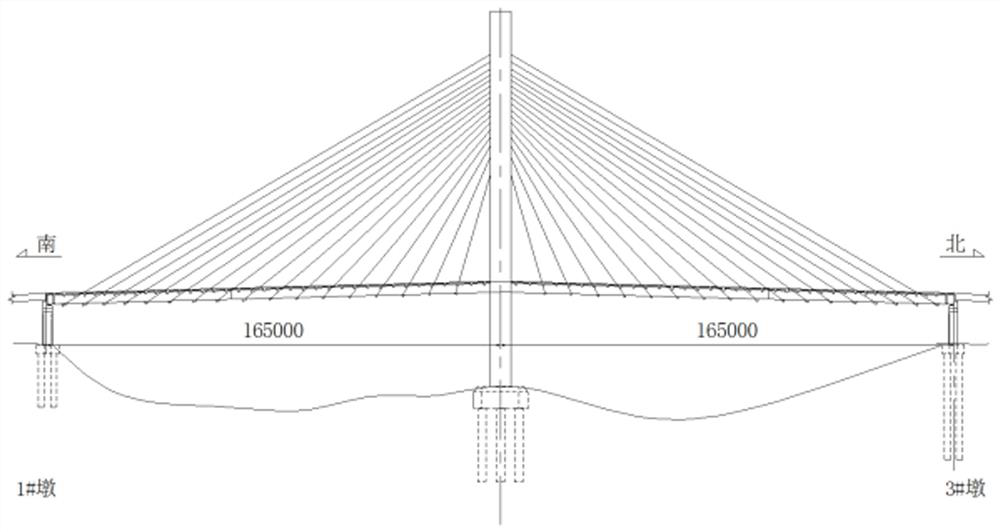

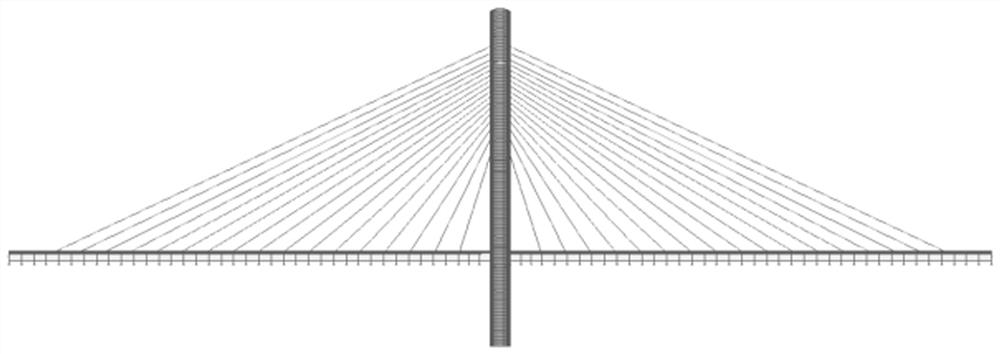

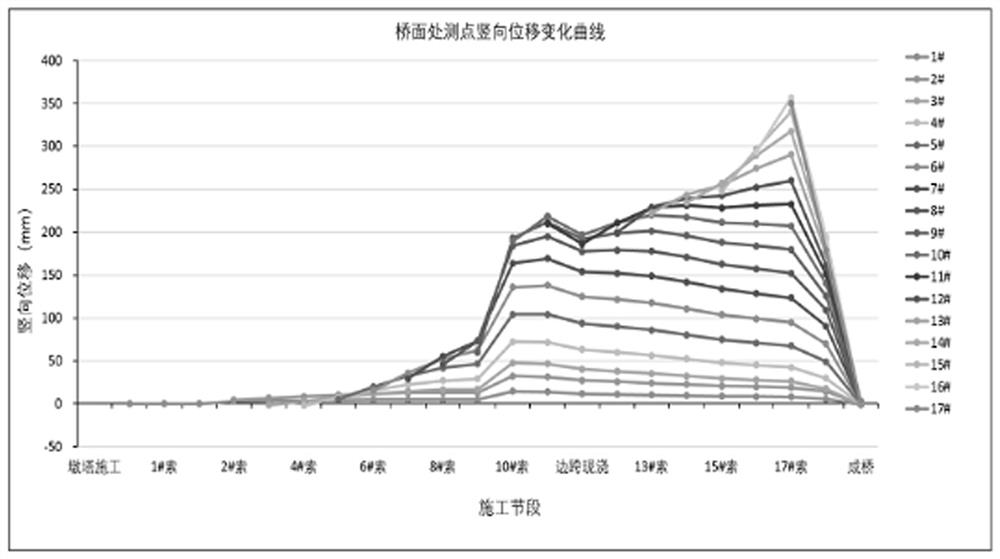

[0047] A cable-stayed bridge has a total length of 330m, and the bridge span is composed of 2×165m. A cable-stayed bridge is designed as a single-tower cable-stayed bridge with double cable planes. The main girder is a steel box girder with a height of 3.5m and a width of 36m. It is a semi-floating system. , standard strength 1960MPa. There are 136 stay cables in the whole bridge, 17 kinds of specifications; the stay cable area is 4200mm 2 、4340mm 2 、4620mm 2 、5054mm 2 、5600mm 2 、6020mm 2 、6440mm 2 、6860mm 2 、7280mm 2 、7770mm 2 、7980mm 2 、8260mm 2 、8820mm 2 、9240mm 2 、9800mm 2 、10640mm 2 、11340mm 2 、4200mm 2 . This project adopts the above-mentioned optimal displacement cable-stayed bridge cantilever construction control method for optimization analysis. Calculation model see figure 2 Shown; the displacement change curve during the construction process is shown in image 3 Shown; the cable stress change curve during the construction process is shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com