Steel rail surface damage detection method based on pulse coupling neural network

A technology of pulse-coupled neural and detection methods, applied in biological neural network models, neural architectures, image data processing, etc., can solve problems such as difficulty in comprehensive coverage, low degree of intelligence, limited and one-sided detection results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

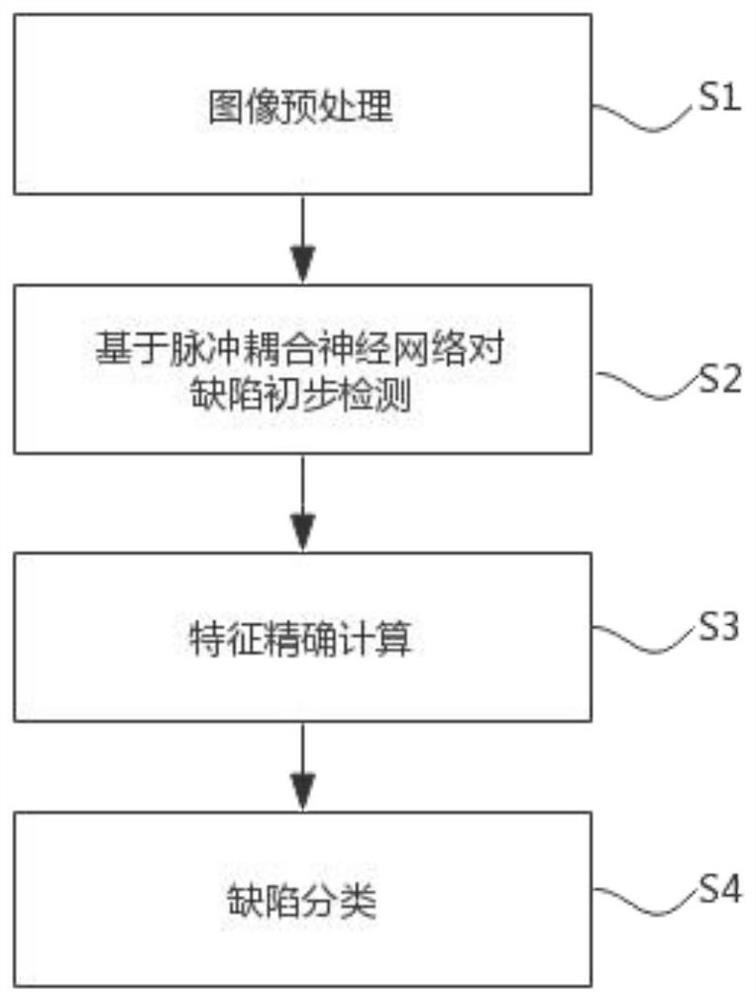

[0077] A rail surface damage detection method based on pulse-coupled neural network detects the position and size of rail surface defects and classifies them through the analysis and processing of image data, and finally points out the type of track defects, which includes the following four steps:

[0078] S1, image preprocessing;

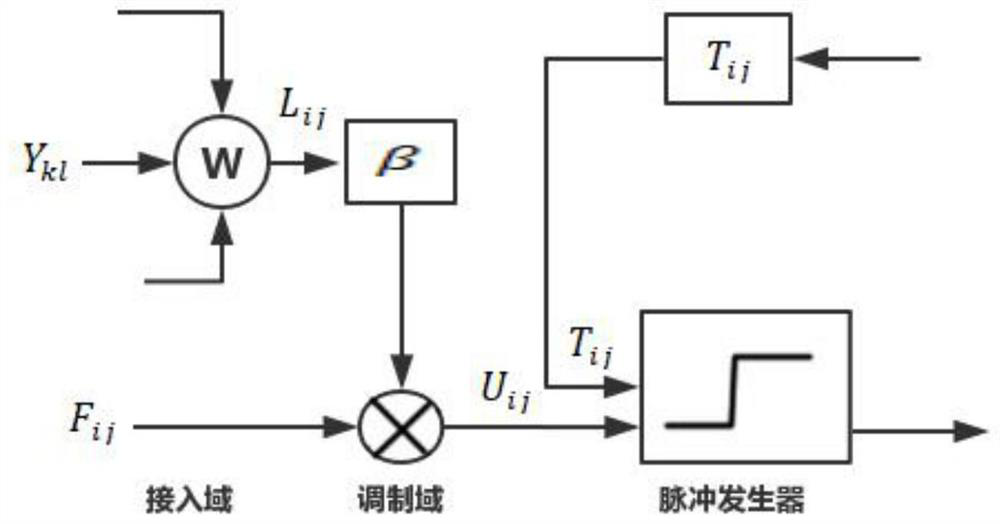

[0079] S2, preliminary detection of defects based on pulse-coupled neural network;

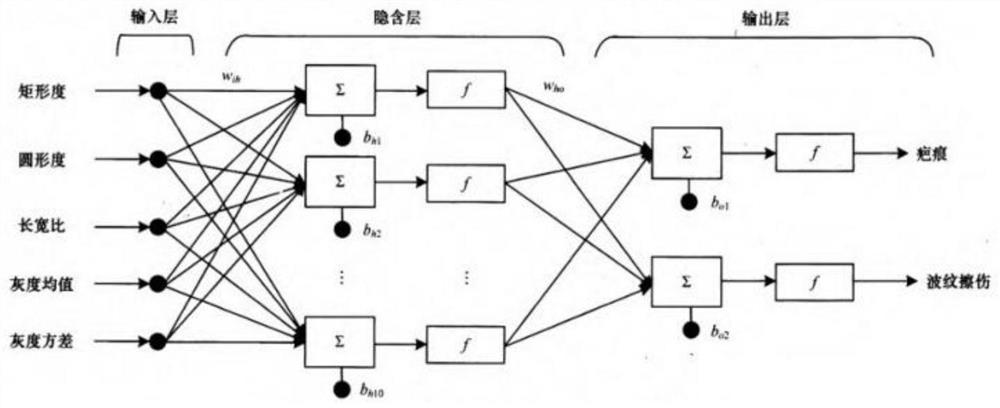

[0080] S3, accurate calculation of features;

[0081] S4, defect classification.

[0082] In the step S1, in the data filtering process of extracting the track part in the image, the present invention adopts the horizontal projection method to extract the rail surface image, because...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com