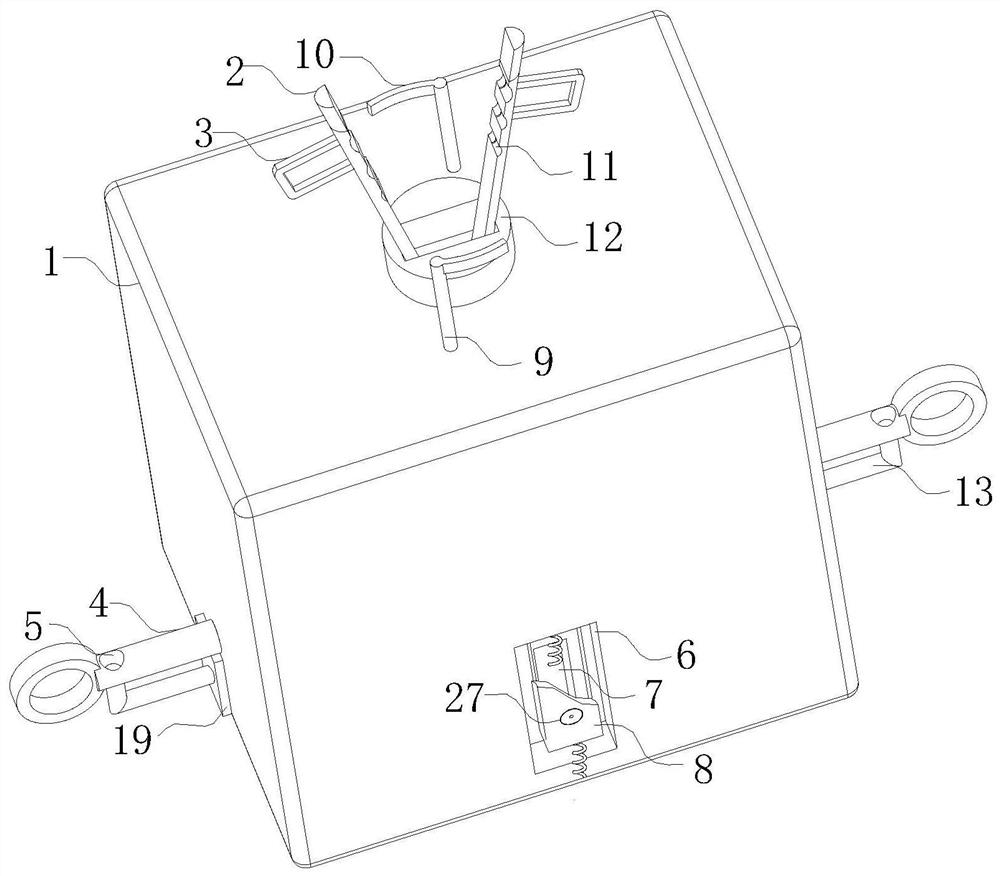

Wiring terminal

A terminal and cable technology, applied in the direction of connection, clamping/spring connection, line/collector components, etc., can solve the problems of inconvenient cable cutting, loose cable ends, poor contact, etc., and improve installation Efficiency, stable current output, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

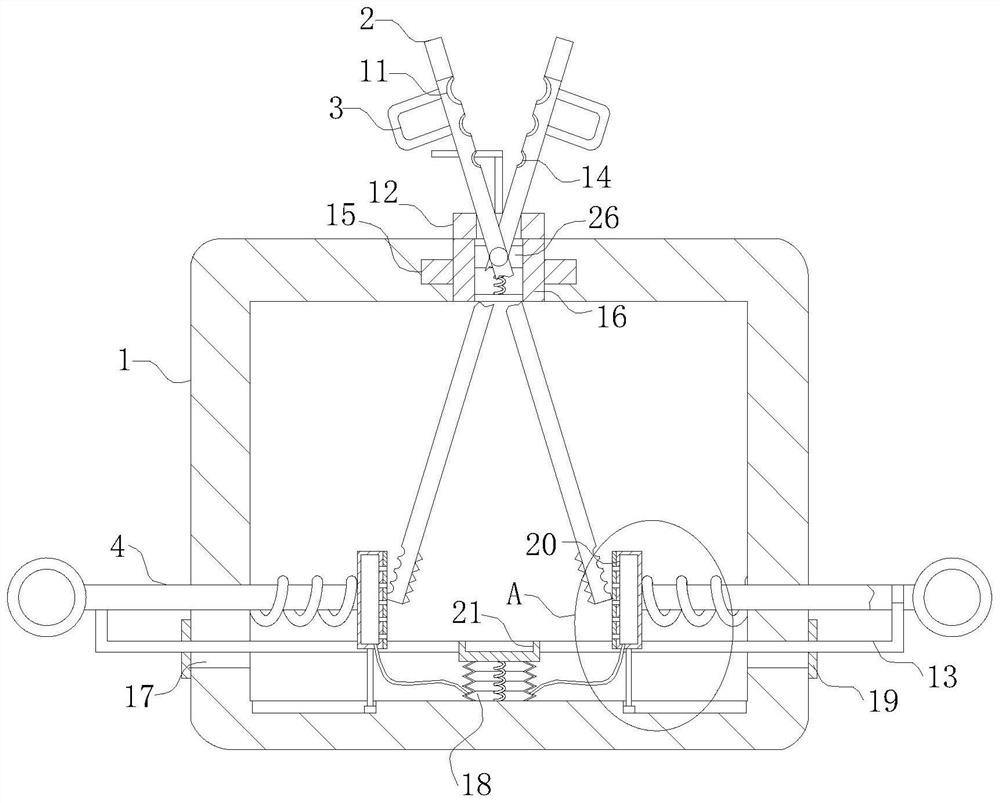

Embodiment approach

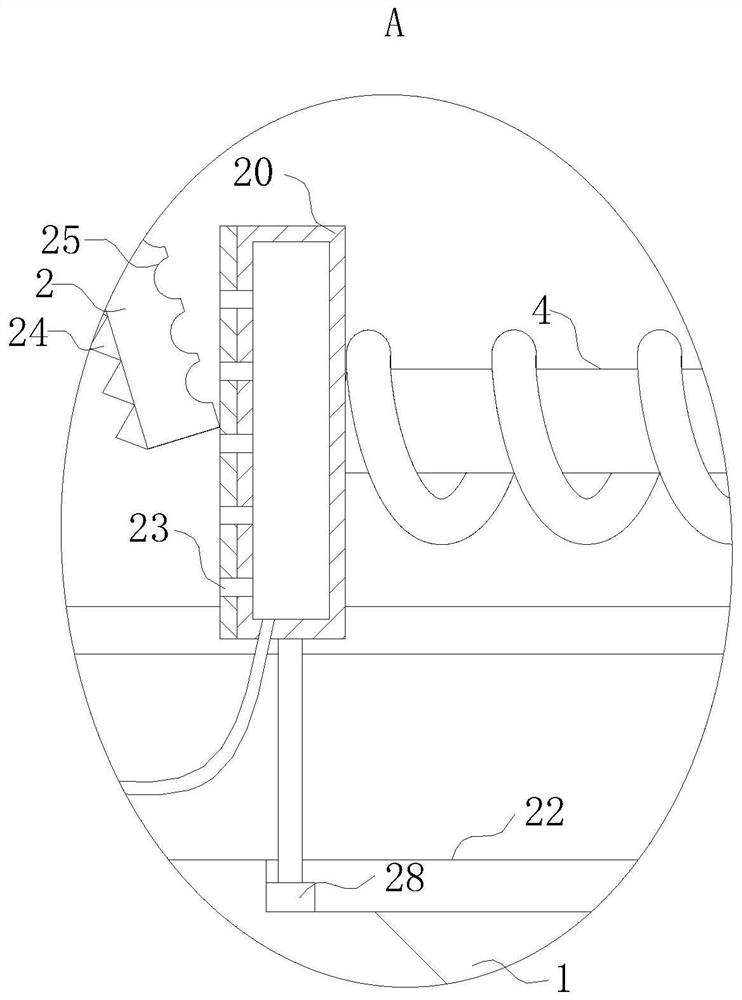

[0025] As an embodiment of the present invention, the clamping device includes a movable rod 4 and a pressing plate 20; the number of the pressing plates 20 is two, and two groups of the pressing plates 20 are respectively located Both sides; the pressing plate 20 is a semicircular arc-shaped plate, and the inner wall of the pressing plate 20 is glued with a rubber anti-skid pad; the outer wall of the pressing plate 20 is fixedly connected with one end of the movable rod 4; the movable rod The other end of 4 protrudes from the side wall of the housing 1 and is fixedly connected with the pull ring; the movable rod 4 is sleeved with a spring between the inner wall of the housing 1 and the pressing plate 20; the pressing plate 20 The bottom end is fixed with a limit slider 28 through a joint bar; the limit slider 28 is slidably connected with the limit chute 22 at the bottom of the housing 1; during work, when the pull ring is pulled to the outside of the housing 1 , the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com