Brake device and power assembly

A technology for braking devices and power components, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of easy generation of heat and dust, small braking torque, increase the volume of power components, etc., and achieve high braking reliability. , The effect of large braking torque and volume saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 of the present application provides a brake device.

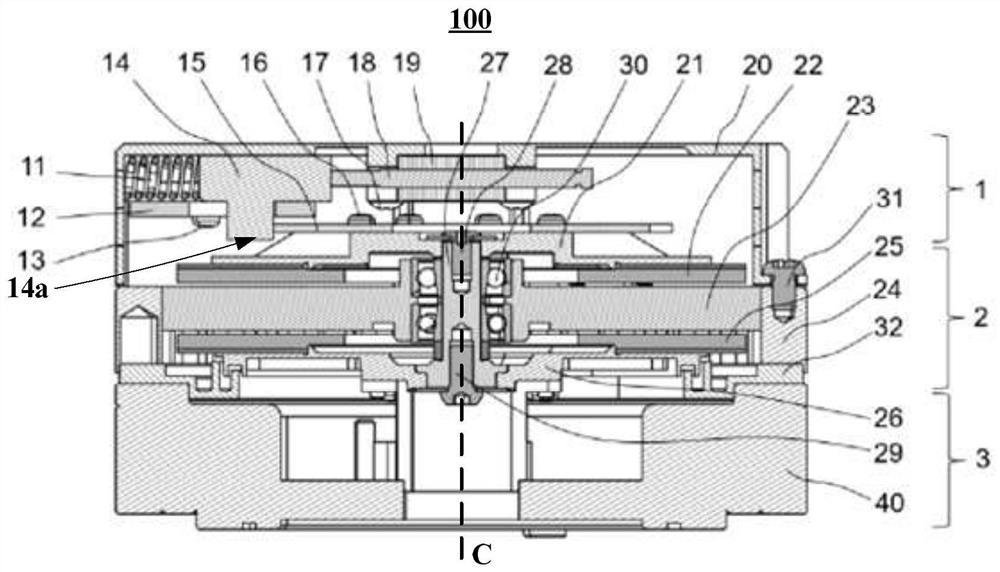

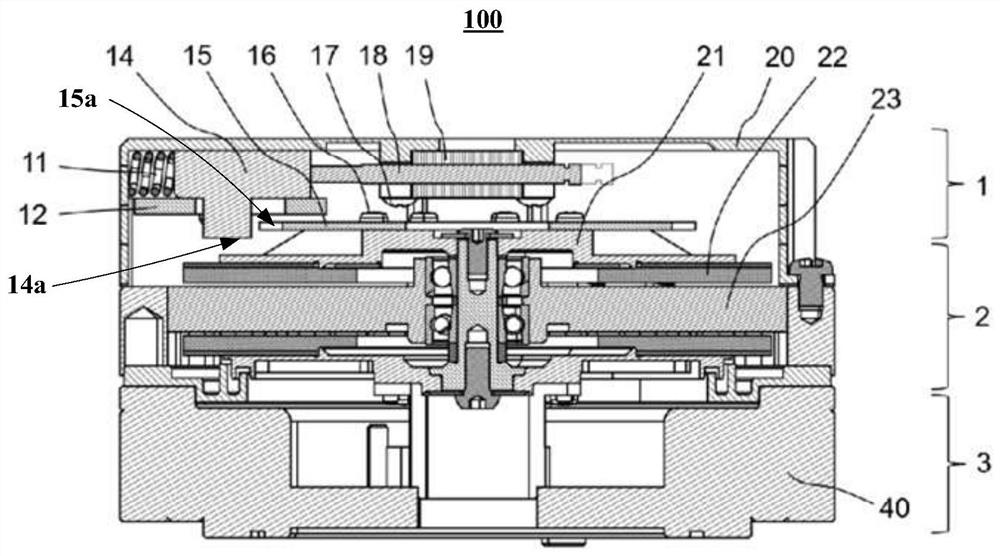

[0042] figure 1 It is a schematic diagram of the braking device of this embodiment installed on the motor and the braking device is in the braking position. Such as figure 1 As shown, the braking device 1 can be installed on the motor 2, and when the braking device 1 is in the braking position, the braking device 1 can brake the motor 2.

[0043] Such as figure 1 As shown, the motor 2 may be an axial flux motor, wherein the motor 2 may have: a rotating shaft 27 rotating around a central axis C; a first rotor 22 arranged radially outside the rotating shaft 27, the first rotor 22 is It can be a magnet, which generates axial magnetic flux; a stator 23 arranged on one axial side of the first rotor 22, for example, the stator 23 is arranged on the front side of the first rotor 22; The first rotor disk 21 on the other axial side of the stator 23, and the first rotor 22 is fixedly mounted on the first rotor...

Embodiment 2

[0075] Embodiment 2 of the present application provides a power assembly, which has the braking device described in Embodiment 1. Since the structure of the braking device has been described in detail in Embodiment 1, its content is incorporated here, and the description is omitted here.

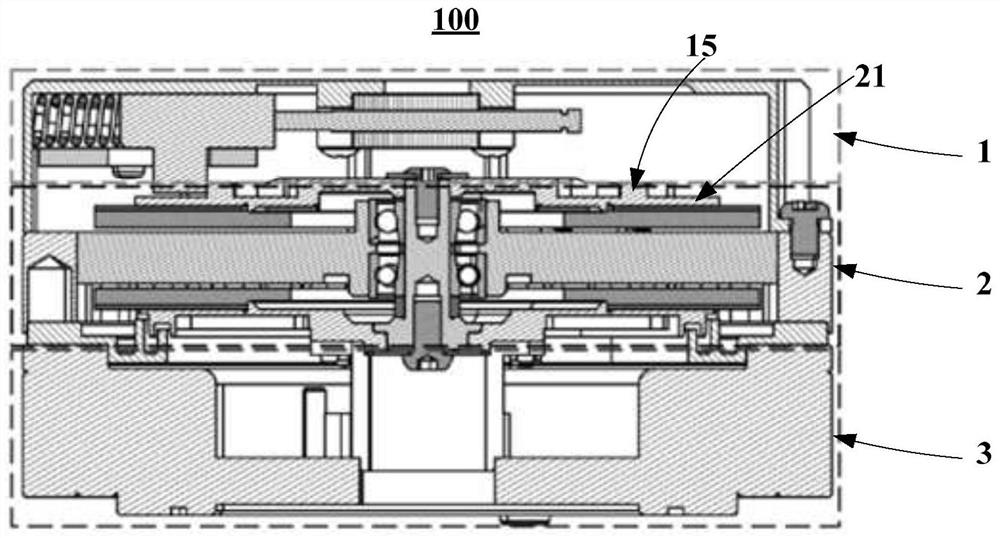

[0076] In this embodiment, the cross-sectional view of the power assembly 100 can be as follows figure 1 , figure 2 , image 3 , Figure 8 or Figure 9 shown. The power assembly 100 may have a braking device 1 and a motor 2 , wherein the braking device 1 is used to brake the motor 2 .

[0077] In this embodiment, the power assembly 100 may also have a speed reduction device 3 , and the speed reduction device 3 may be disposed on a side of the stator 23 away from the first rotor 22 in the axial direction. Wherein, the speed reduction device 3 is connected with the output end of the rotating shaft 27 of the motor 2, and the speed reducing device 3 transmits the power of the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com