A desulfurization and denitrification system based on electrolysis of seawater and its process

A desulfurization and denitrification, seawater technology, applied in the field of desulfurization and denitrification systems, can solve the problems of difficulty in providing installation space and conditions, difficulty in improving desulfurization and denitrification efficiency, and low spray density and intensity, so as to reduce system energy consumption and improve space utilization. good thermal conductivity and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

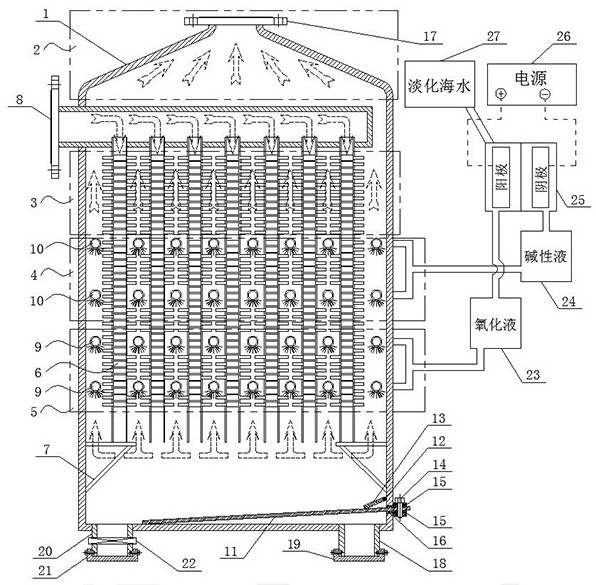

[0037] A desulfurization and denitrification system based on electrolytic seawater of the present invention includes a tower body 1, a flue gas pipeline 8, a needle-shaped plate device 6, a first spray layer and a second spray layer; the specific structure is as follows figure 1 As shown, a flue gas outlet 17 is connected to the middle position of the top of the tower body 1, and a drain pipe 20 is vertically connected to the bottom side of the tower body 1; Cover 21, the second sealing cover 21 is matched with the discharge pipe 20, and the two are sealed and screwed together; a solenoid valve 22 is also socketed and fixed on the discharge pipe 20, and the solenoid valve 22 is located on the second sealing Between the cover 21 and the bottom of the tower body 1, it is used to control the discharge of waste liquid.

[0038] In the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com