Structure for preventing cracking and water leakage of concrete dam bank slope dam section

A technology for concrete dams and water seepage, applied in dams, gravity dams, water conservancy projects, etc., can solve the problems of cumbersome construction process, poor effect, labor, time and money, etc. Good effect and convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

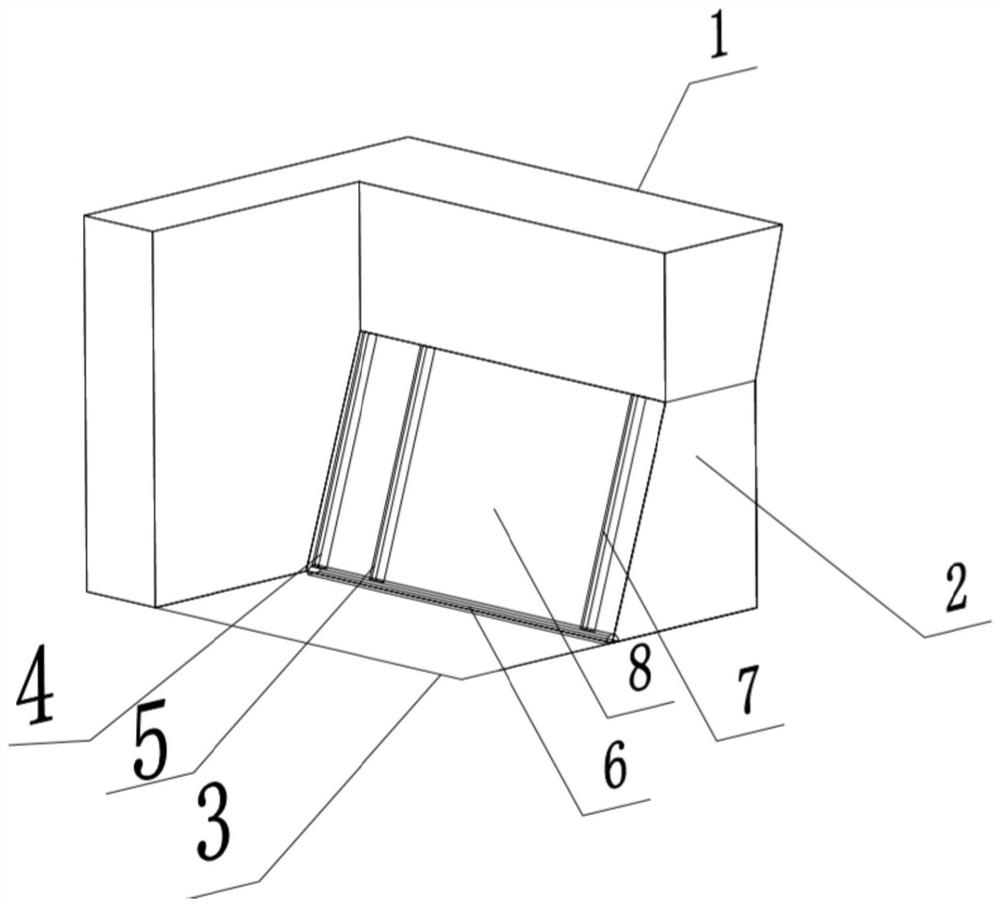

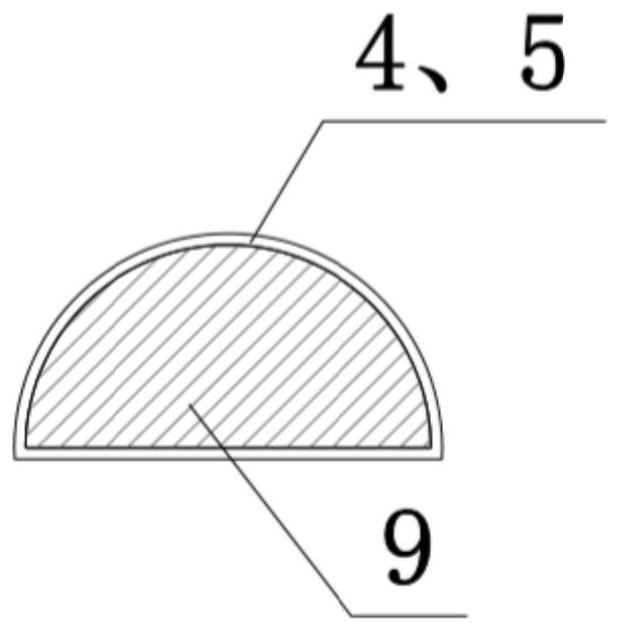

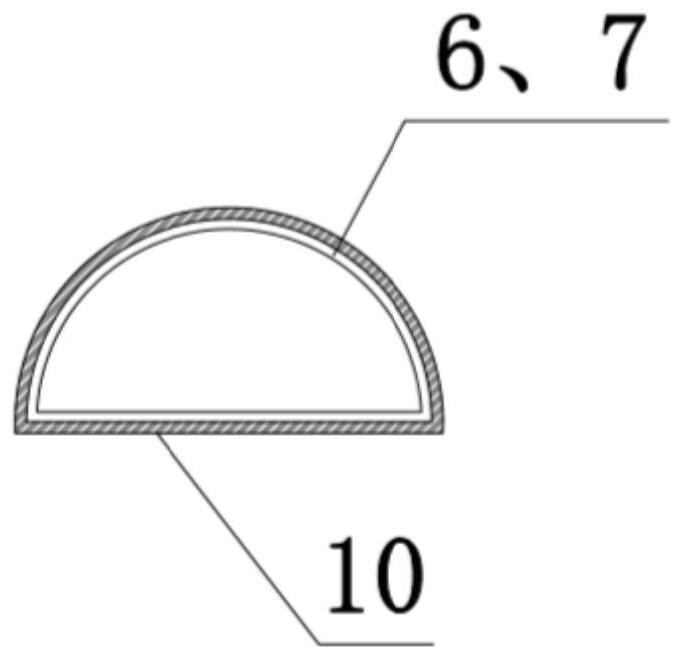

[0012] Such as figure 1 As shown, a structure for preventing concrete dam bank slope dam section from cracking and leaking water, including bank slope dam section dam body 1, bank slope bedrock 2, bank slope bedrock surface 8, bank slope bedrock plane 3, in Inside the dam body 1 of the bank slope dam section, the first row of semicircular permeable pipes 4 and the second row of semicircular permeable pipes 5 are arranged on the bedrock surface 8 of the bank slope slope, and the inside of the first row of semicircular permeable pipes 4 and the second row of semicircular permeable pipes 5 Clay 9 is filled, inside the dam body 1 of the bank slope dam section, and on the bedrock surface 8 of the bank slope slope, a semicircular permeable drainage pipe 7 is arranged along the slope, inside the dam body 1 of the bank slope dam section, on the bedrock ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com