Experimental device for real-time monitoring of sealing integrity of cementing sheath

An experimental device and cementing cement technology, which is applied in measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems of not being able to provide cementing cement sheath sealing performance monitoring, etc., to reduce the cost of the experiment, measure the value accurately, The effect of real-time continuous monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: An experimental device for real-time monitoring of the integrity of the cement sheath seal when simulating the cement slurry returning to insufficient height

[0028] Embodiment 1 provides an experimental device for real-time monitoring of the sealing integrity of the cement sheath, and its structure will be described in detail below.

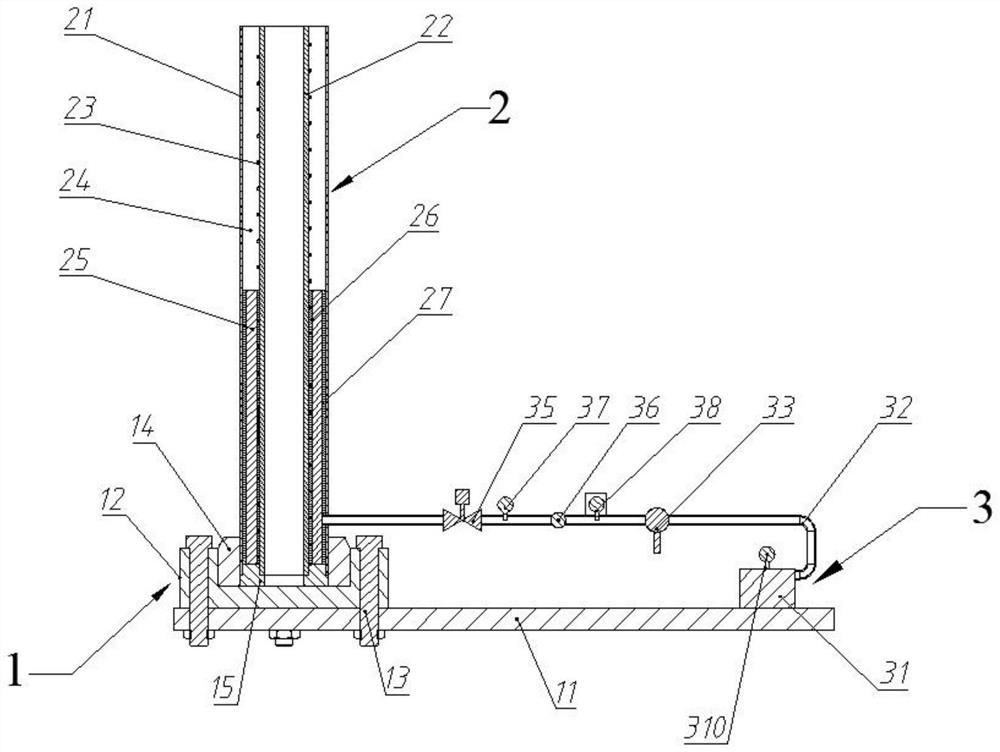

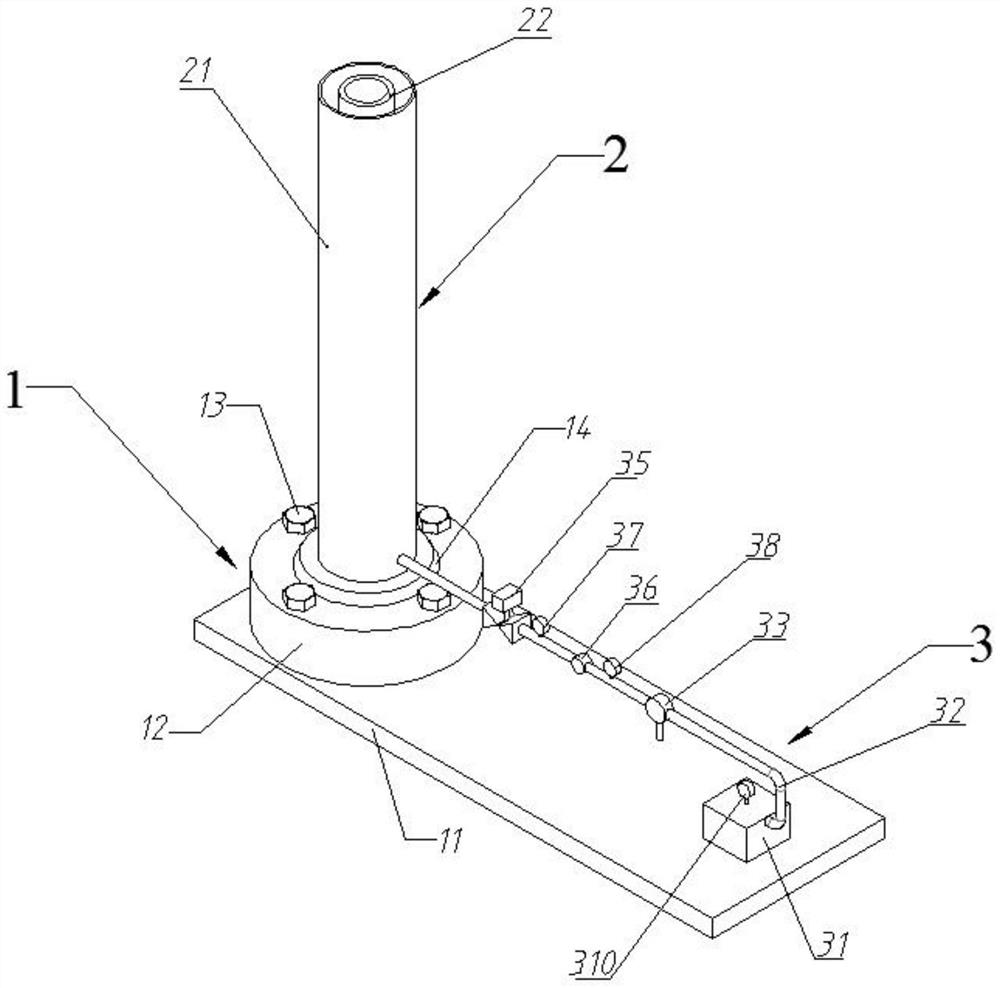

[0029] refer to Figure 1 to Figure 2 , the device includes a fixture 1 , a wellbore device 2 and a cement slurry injection system 3 .

[0030] The fixing device 1 includes a base plate 11 , a base 12 , several fixing bolts 13 , a fixing ring 14 , and a bottom positioning ring 15 .

[0031] Wherein, the base plate 11 is a rectangular plate, the shape of the base 12 is a hollow cylinder, a circular groove is arranged in the middle of the base 12, a plurality of bolt holes are arranged circumferentially at intervals around the base 12, and corresponding bolt holes are provided at the end of the base plate 11. Perforation, a nu...

Embodiment 2

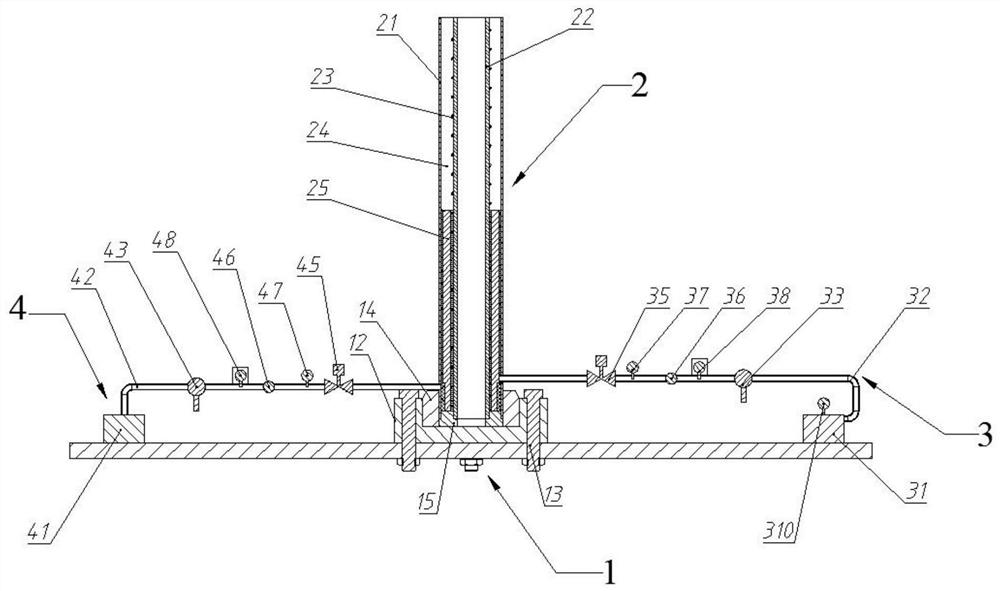

[0041] Example 2: Experimental device for real-time monitoring of seal integrity when simulating well cemented cement sheath cemented surface cracks

[0042] Embodiment 2 On the basis of Embodiment 1, a dyeing liquid injection system 4 is added.

[0043] refer to image 3 with Figure 4 , the dyeing liquid injection system 4 includes a dyeing liquid storage device 41, a dyeing liquid injection pipe 42 and a dyeing liquid pump 43, the dyeing liquid storage device 41 is arranged on the substrate 11, between the dyeing liquid storage device 41 and the cement sheath cavity 24 It communicates with the dyeing liquid injection pipe 42, and the dyeing liquid injection pipe 42 is provided with a dyeing liquid injection pump 43.

[0044] Among them, the function of the dyeing liquid injection system 4 is to inject the dyeing liquid in the dyeing liquid storage device 41 into the bottom of the second cementing surface 27 of the cement sheath, and under the action of the injection press...

Embodiment 3

[0050] Example 3: Experimental device for real-time monitoring of seal integrity when simulating cement sheath oil and gas leakage

[0051] Embodiment 3 On the basis of Embodiment 1, an oil and gas storage device 50 and a set of oil and gas injection system 5 are added.

[0052] refer to Figure 5 with Image 6 , the cement sheath cavity 24 is filled with cement slurry to form a cement sheath 25 whose height is equal to the height of the cement sheath cavity 24 . The cement sheath 25 is provided with an oil and gas channel. It is worth mentioning that, in order to set the oil-gas channel in the cement sheath 25 , it is necessary to pre-embed U-shaped pipe fittings in the wall of the outer cylinder 21 .

[0053] The oil and gas injection system 5 includes an oil and gas injection pipe 51, an oil and gas discharge pipe 52, an oil and gas injection pump 53 and a set of control devices,

[0054] The oil and gas inlet end of the oil and gas injection pipe 51 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com