LED vacuum packaging process and vacuum pressing device

A technology of vacuum packaging and vacuum pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 , 2 , 3, and 5, a vacuum packaging process for LEDs, comprising the following steps:

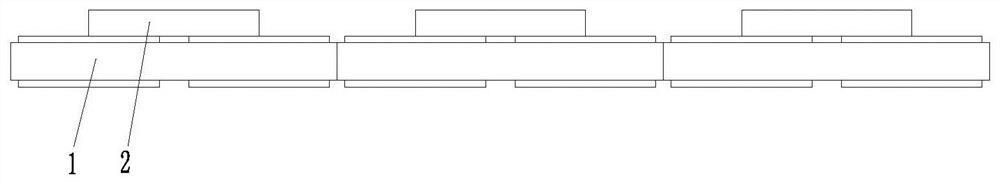

[0027] (1) Die bonding on the substrate 1, and the chip 2 is flipped on the substrate 1;

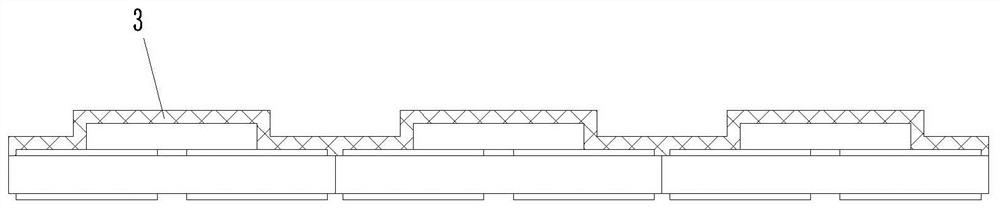

[0028] (2) Press the edge of the fluorescent soft film 3 on the substrate 1 in a vacuum environment, and the inner part of the fluorescent soft film 3 located at the pressed edge is not pressed, and the chip mounting area 4 is formed between the substrate 1 and the fluorescent soft film 3 ;

[0029] (3) Unload the vacuum;

[0030] (4) Baking and curing the fluorescent soft film 3;

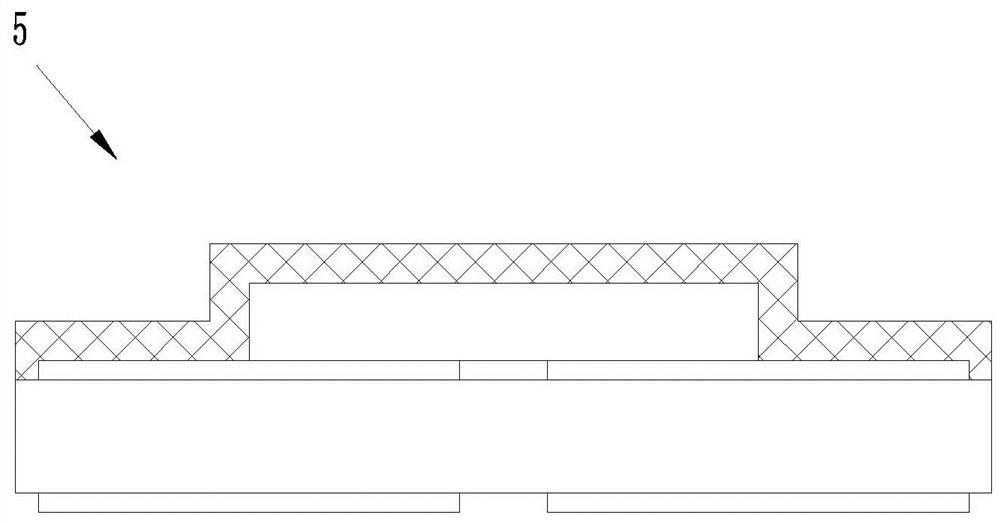

[0031] (5) Segmentation and cutting of the substrate 1 to form a single packaged LED 5 .

[0032] Such as Figure 4 As shown, the structure of the vacuum pressing device used in the above step (2) is as follows: the vacuum pressing device includes a vacuum chamber 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com