Patents

Literature

33results about How to "Eliminates coating process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

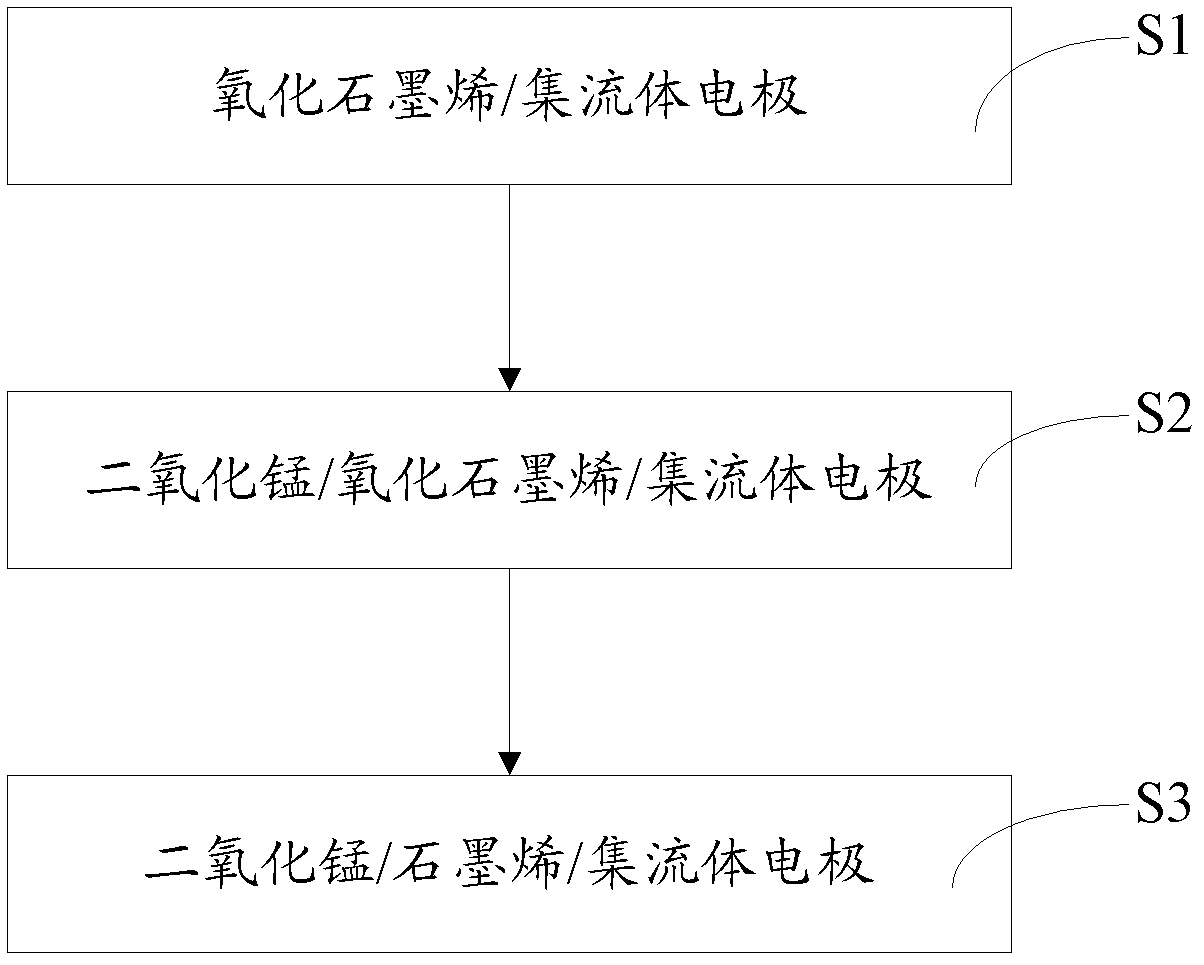

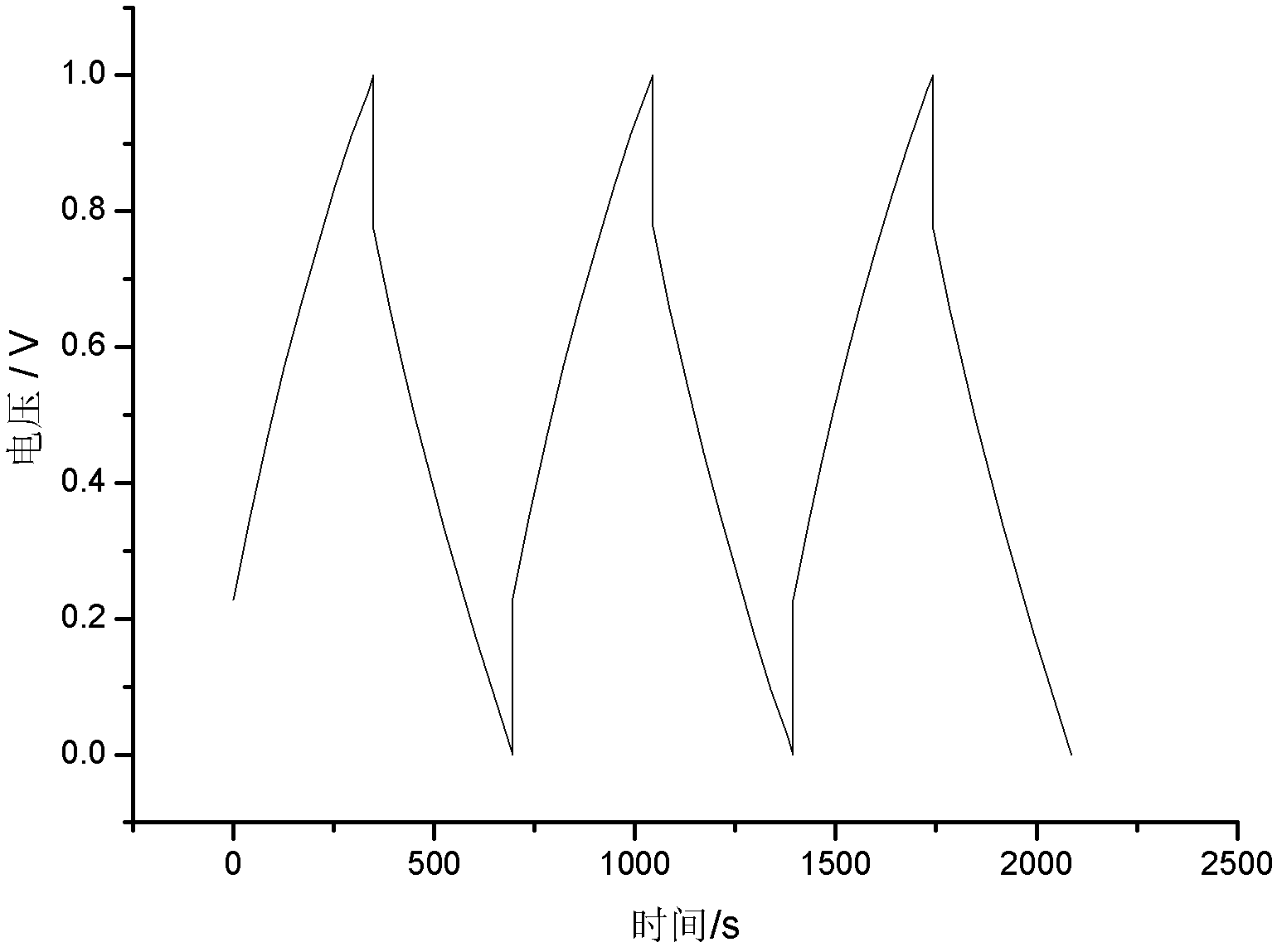

Graphene composite electrode and preparation method and application

ActiveCN103035409ALower equivalent series resistanceImprove stabilityLiquid electrolytic capacitorsCell electrodesCapacitanceComposite electrode

The invention provides a graphene composite electrode which comprises a current collector and electrode active materials arranged on the surface of the current collector, wherein the electrode active materials comprise graphene and manganese dioxide. The graphene is in a stratified structure and is arranged on the surface of the current collector, and the manganese dioxide is arranged on the surface of the graphene in the stratified structure. Mass percentage content of the graphene in the electrode active materials is 80%-90%. In addition, the invention further relates to a preparation method and an application of the graphene composite electrode. Oxidized graphene and the manganese dioxide are deposited on the current collector step by step, adhesion agents are not needed, and therefore equivalent series resistance of the whole electrode is reduced effectively, capacity and pseudocapacitance of an electric double-layer of the graphene and the manganese dioxide are developed simultaneously, and stability and conductivity of the electrode are well improved by addition of the graphene. In addition, through the method of electro-deposition, the electrode materials are directly deposited on an electrode plate, a complex coating process is saved, the process is simple, and time is short.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

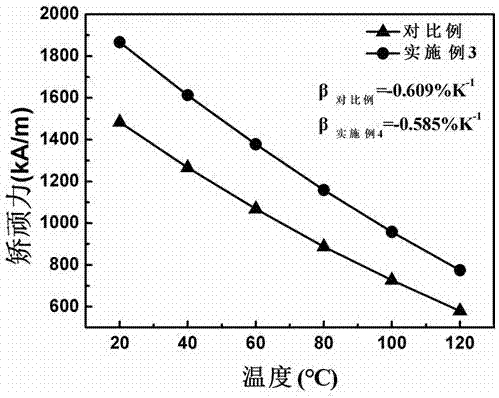

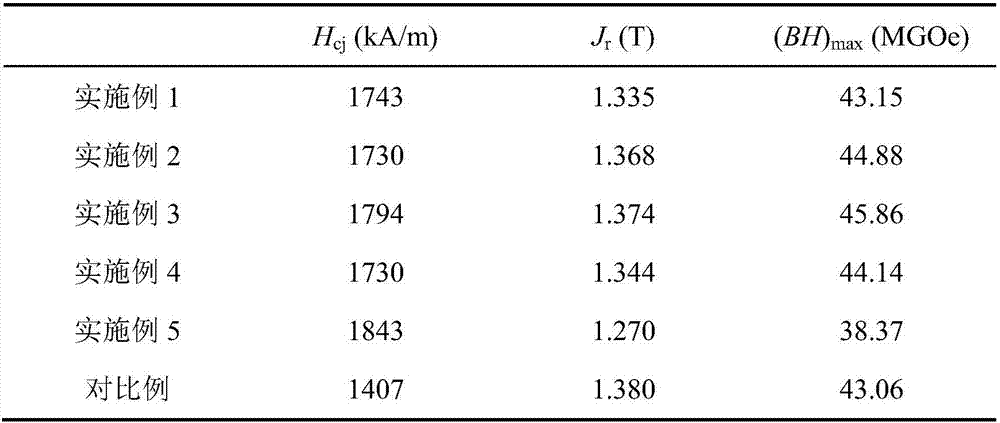

Crystal boundary diffusion method for improving coercive force and thermal stability of neodymium-iron-boron magnet

InactiveCN107093516ADiffusion rate is fastInhibit growthInductances/transformers/magnets manufactureRare earthHeat treated

The invention discloses a crystal boundary diffusion method for improving the coercive force and the thermal stability of a neodymium-iron-boron magnet, and belongs to the field of rare earth permanent magnet materials. According to the method, a quaternary alloy Dy-Ni-Al-Cu with a low melting point is used as a diffusion source and melted and prepared into a rapid-hardening strip, after coarse breaking, the strip casting is laid around the neodymium-iron-boron magnet, and by the adoption of a heat treatment method, the rapid-hardening strip diffuses and enters the magnet along the crystal boundary. After the processing, the coercive force of the magnet is significantly improved, and the magnetic energy product is improved to a certain extent; meanwhile, since the temperature of the diffusion treatment is low, energy consumption can be reduced, the cost can be lowered, and Nd2Fe14B crystal grains can be prevented from growing up; compared with a coating and magnetron sputtering method, the crystal boundary diffusion method omits a powder preparing and coating process in a coating technology and a thin film preparing process in a magnetron sputtering technology. After the technology processing of the crystal boundary diffusion method, the neodymium-iron-boron magnet with the high coercive force and the high thermal stability is finally obtained.

Owner:SOUTH CHINA UNIV OF TECH

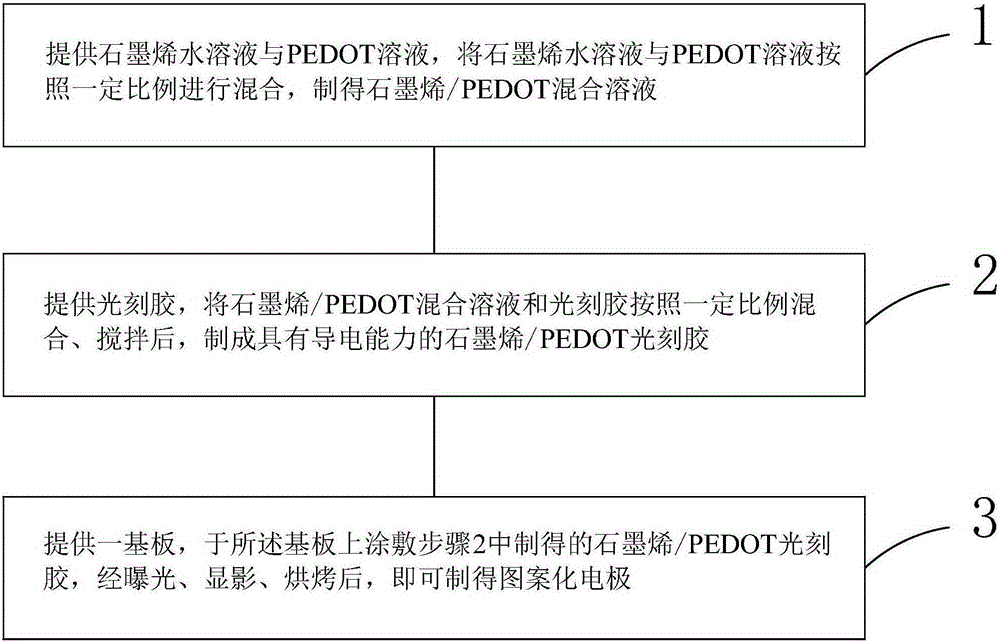

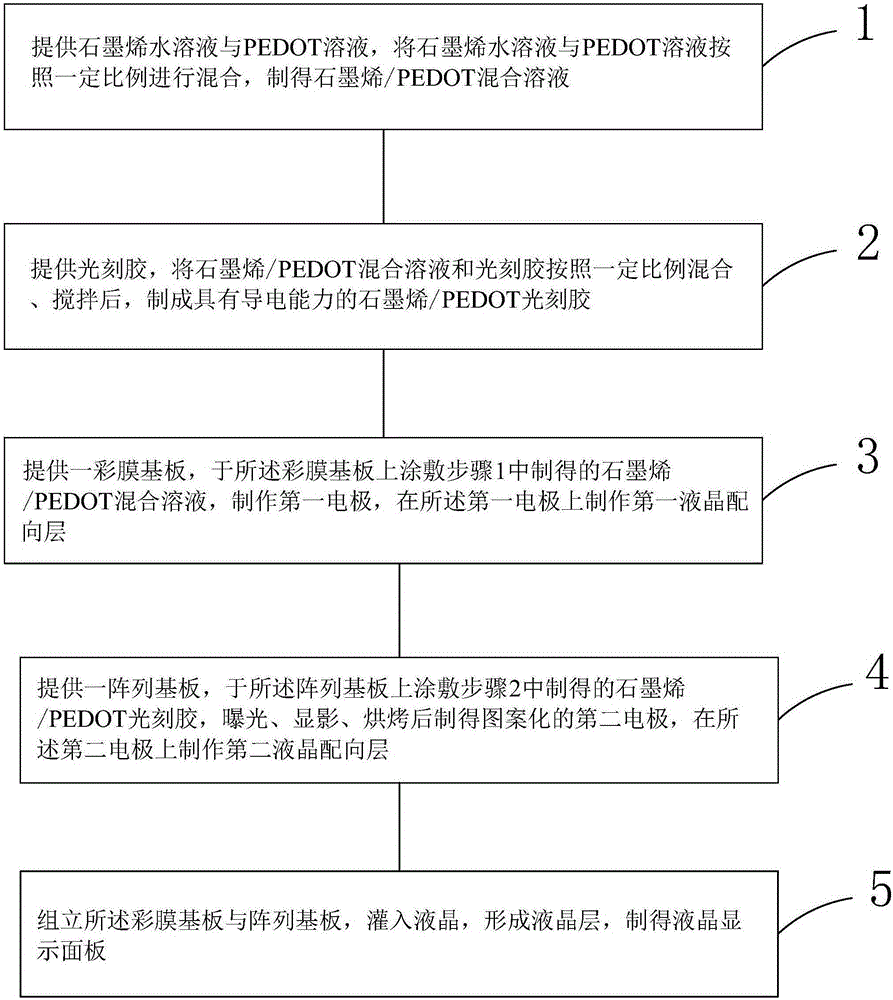

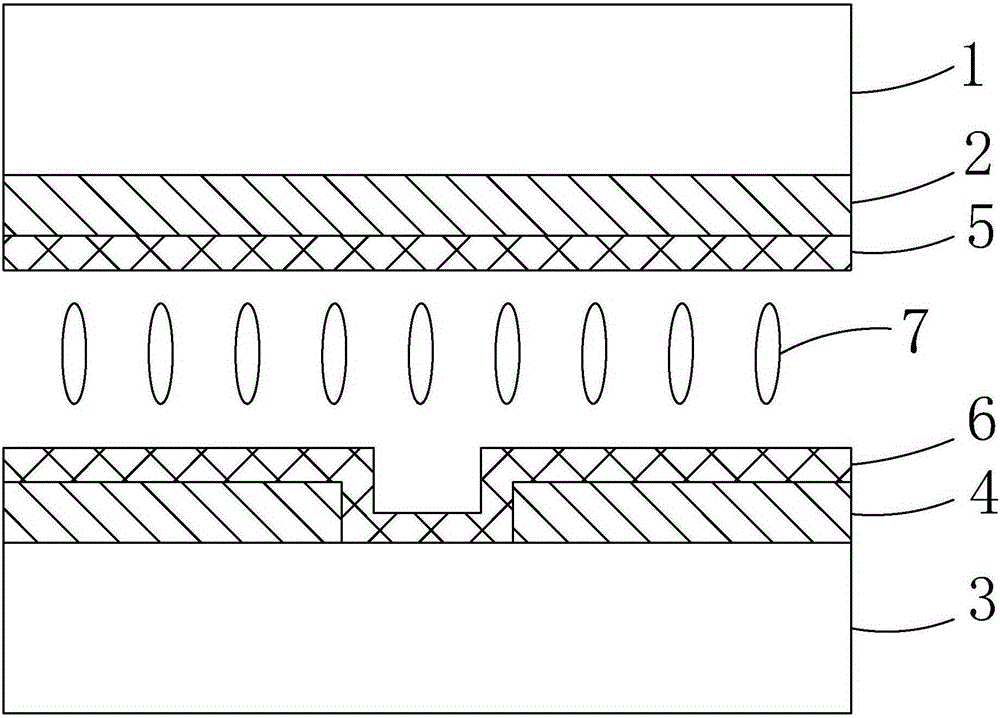

Patterned electrode manufacturing method, liquid crystal display panel and liquid crystal display panel manufacturing method

InactiveCN105259715ALow costEliminates coating processNon-linear opticsLiquid-crystal displayGraphene

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

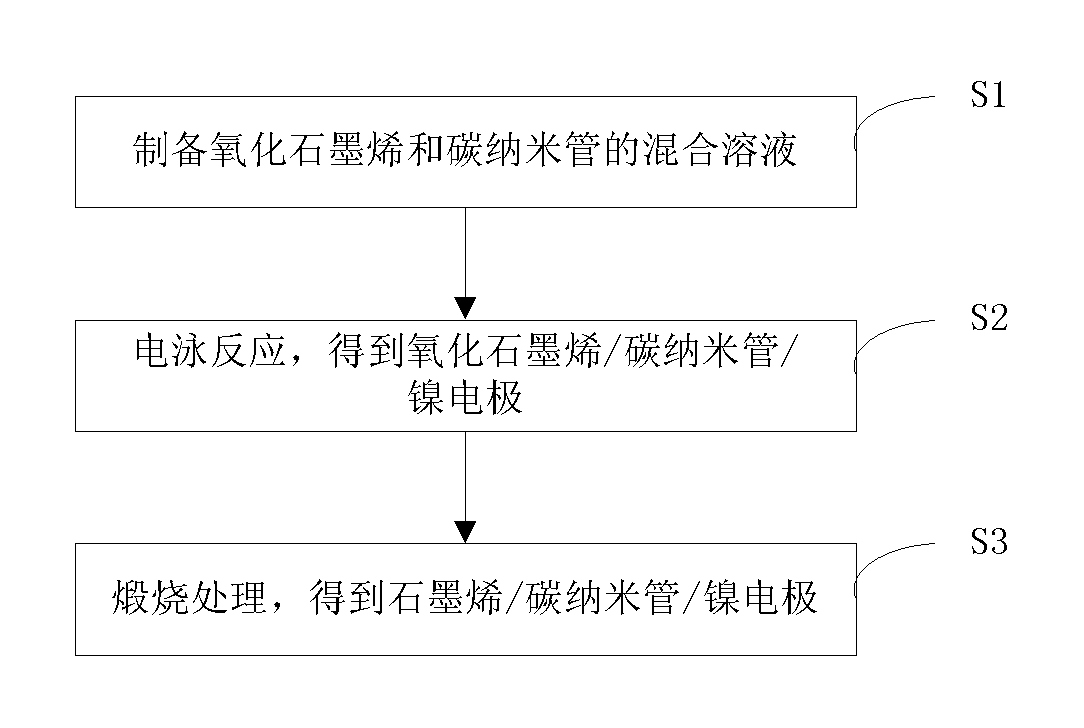

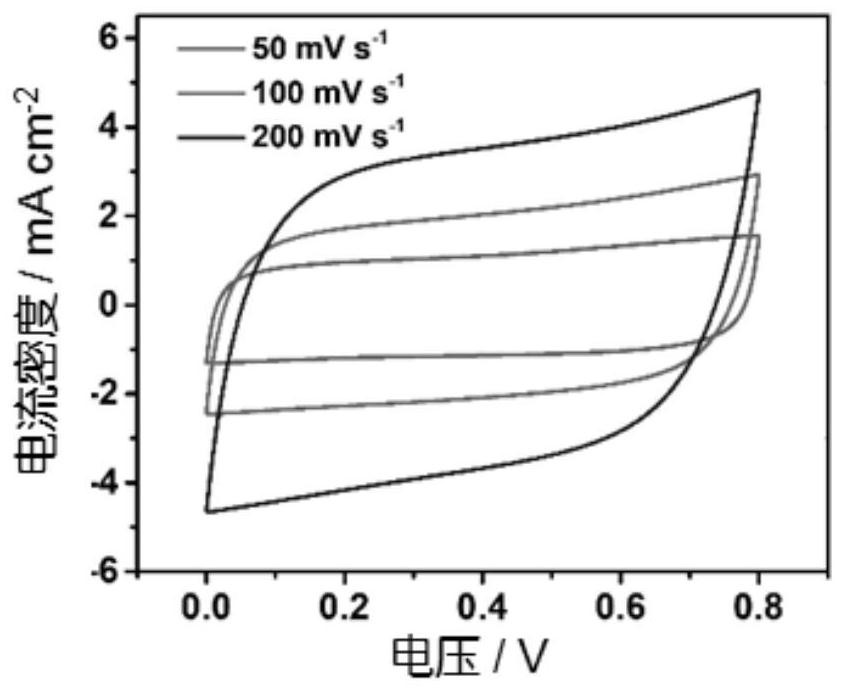

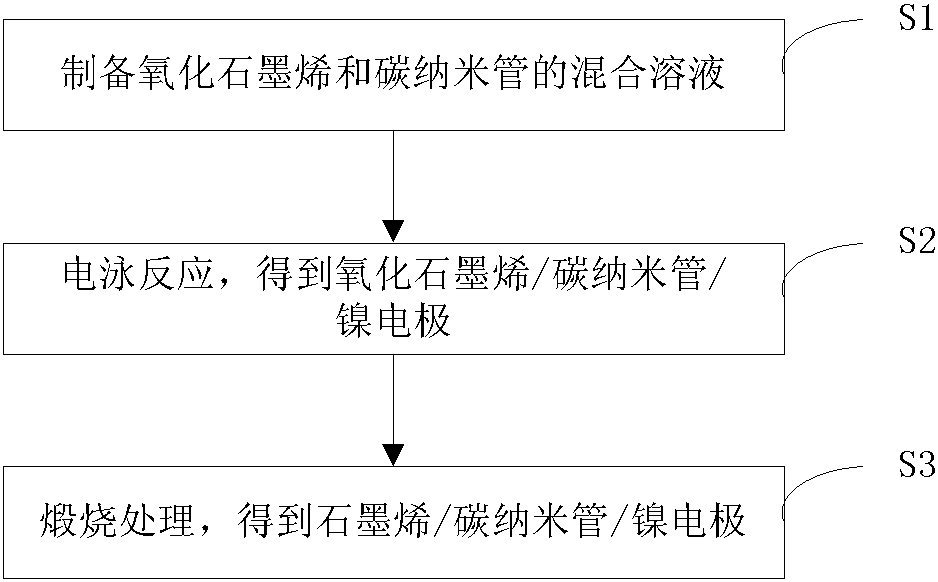

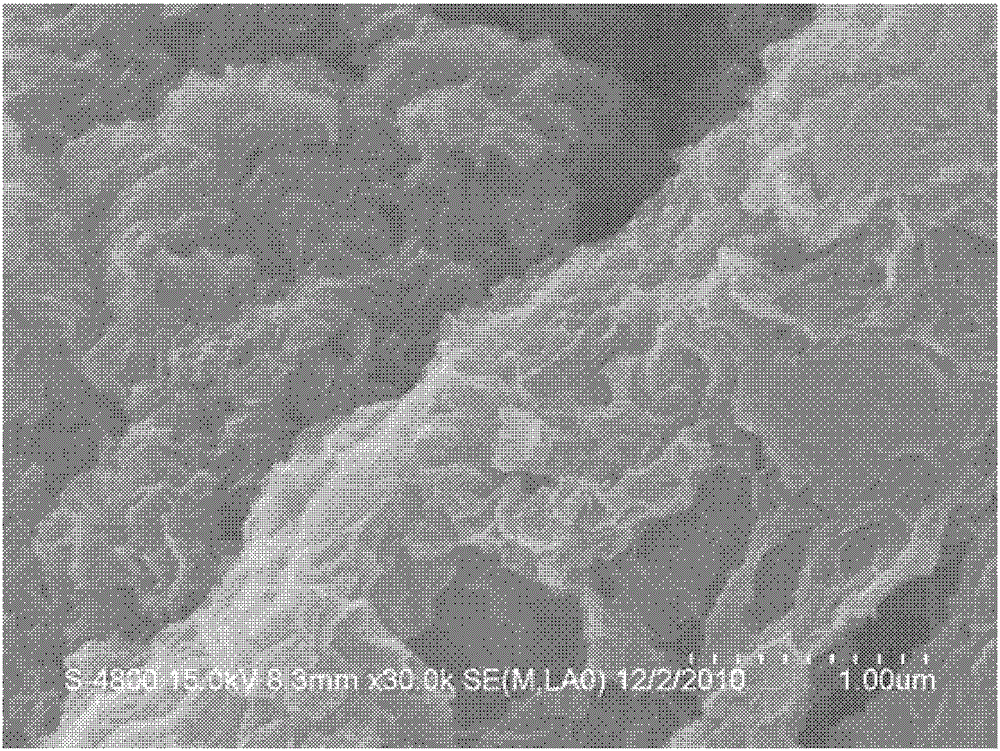

Graphene/carbon nano tube/nickel electrode and preparation method and application of grapheme/carbon nano tube/nickel electrode

ActiveCN102760582AEasy to insertThe effect of complementary performance is goodElectrolytic capacitorsCell electrodesCarbon nanotubeNickel electrode

The invention belongs to the field of electrochemical materials, and discloses a grapheme / carbon nano tube / nickel electrode and a preparation method thereof. The preparation method of the composite material comprises the following steps: a graphene oxide and carbon nano tube mixed solution is prepared; a graphite oxide / carbon nano tube / nickel electrode is prepared through electrophoresis; and the grapheme / carbon nano tube / nickel electrode is prepared. The invention provides the preparation method of the grapheme / carbon nano tube / nickel electrode; as the graphite oxide / carbon nano tube material is directly deposited on an electrode plate, a complicated coating process can be omitted, the process is simple, and the time is short; in addition, equivalent series resistance (ESR) of the graphite oxide / carbon nano tube / nickel electrode is reduced, so that the power density of a super capacitor is increased more efficiently.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

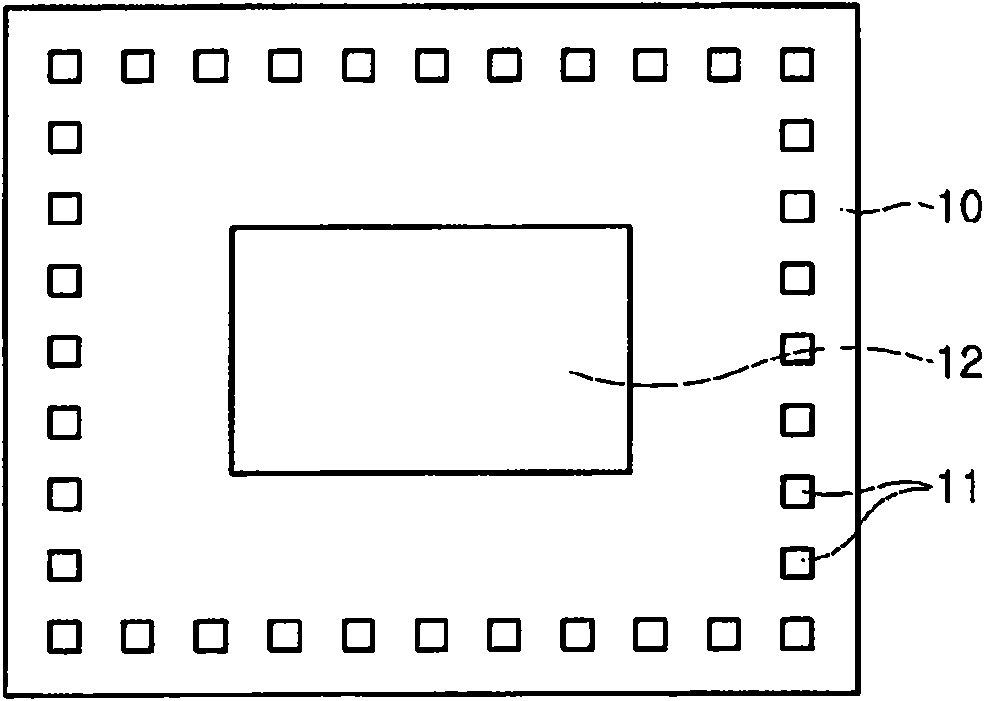

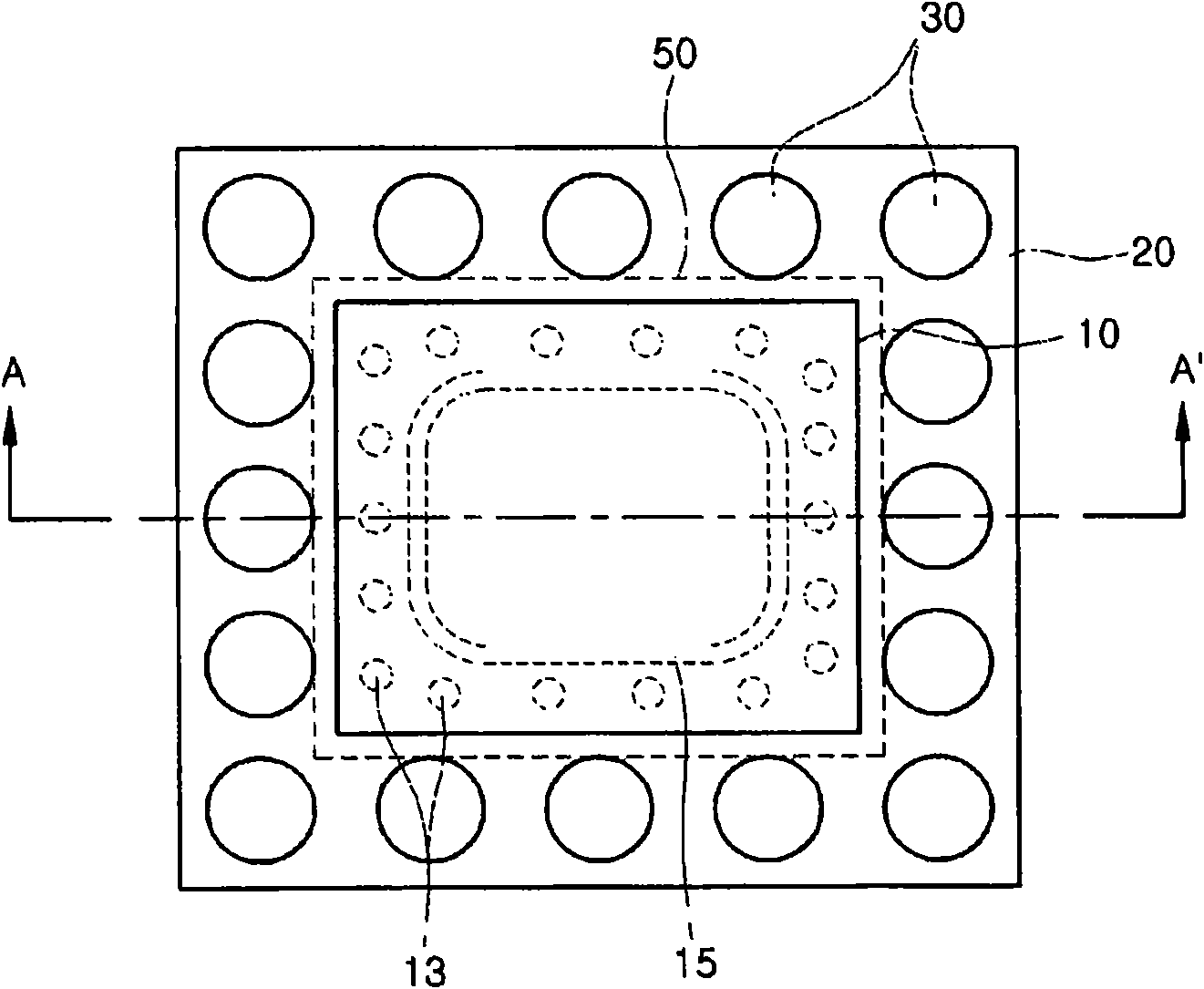

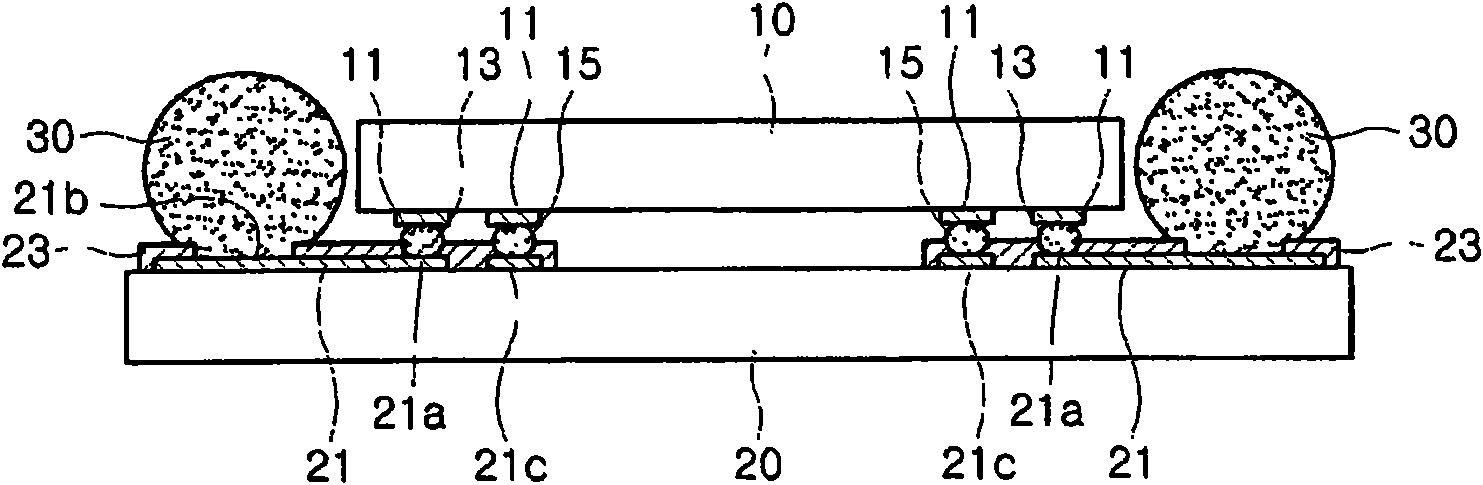

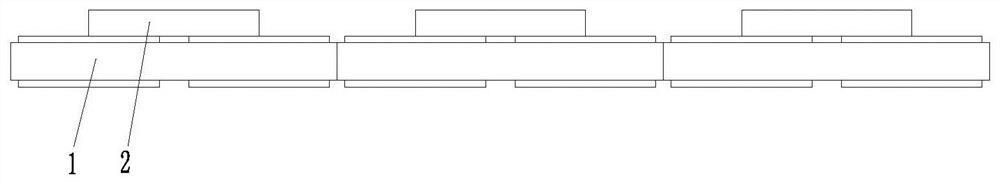

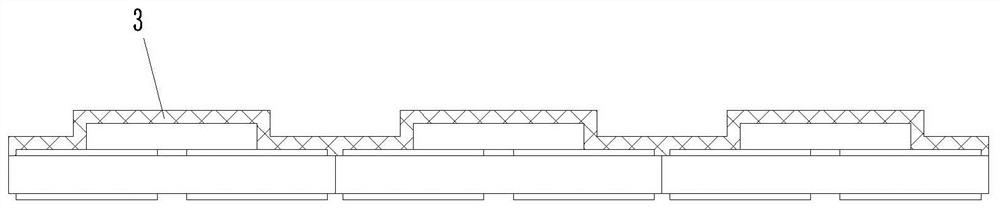

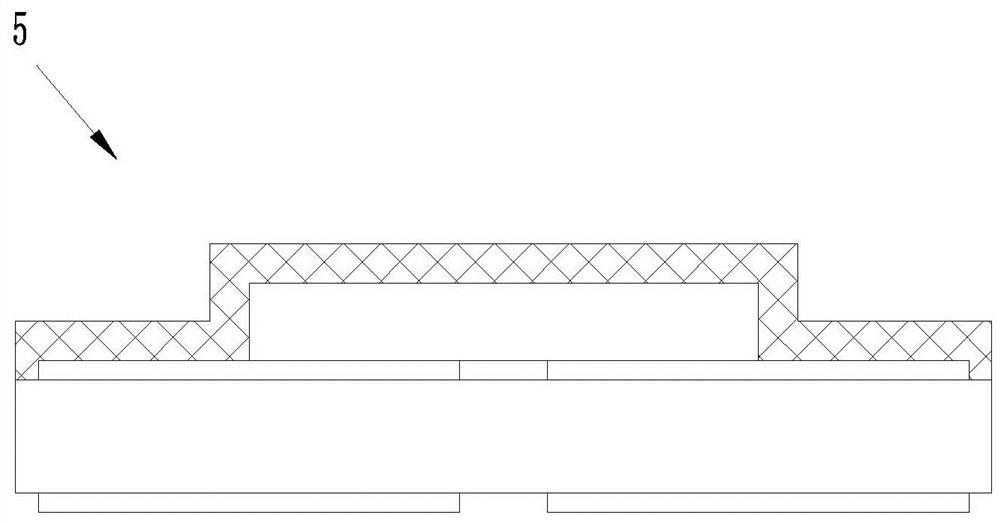

Package for semiconductor device and packaging method thereof

InactiveCN101681854AReduce processing timeEliminates coating processSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device package and a method thereof are able to reliably package a semiconductor device on a substrate without using flux. The semiconductor device package includes a semiconductor device and a substrate reciprocally disposed with respect to the semiconductor device, wherein the substrate includes a side reciprocal to the semiconductor device on which there are formed a plurality of prominences surrounding an accommodation region where the semiconductor device is to be disposed. The method of packaging a semiconductor device includes preparing the semiconductor device, preparing a substrate, forming a plurality of prominences to surround an accommodation region on the substrate where the semiconductor device is to be disposed, dropping the semiconductor device within the accommodation region, and packaging the semiconductor device on the substrate.

Owner:OPTOPAC

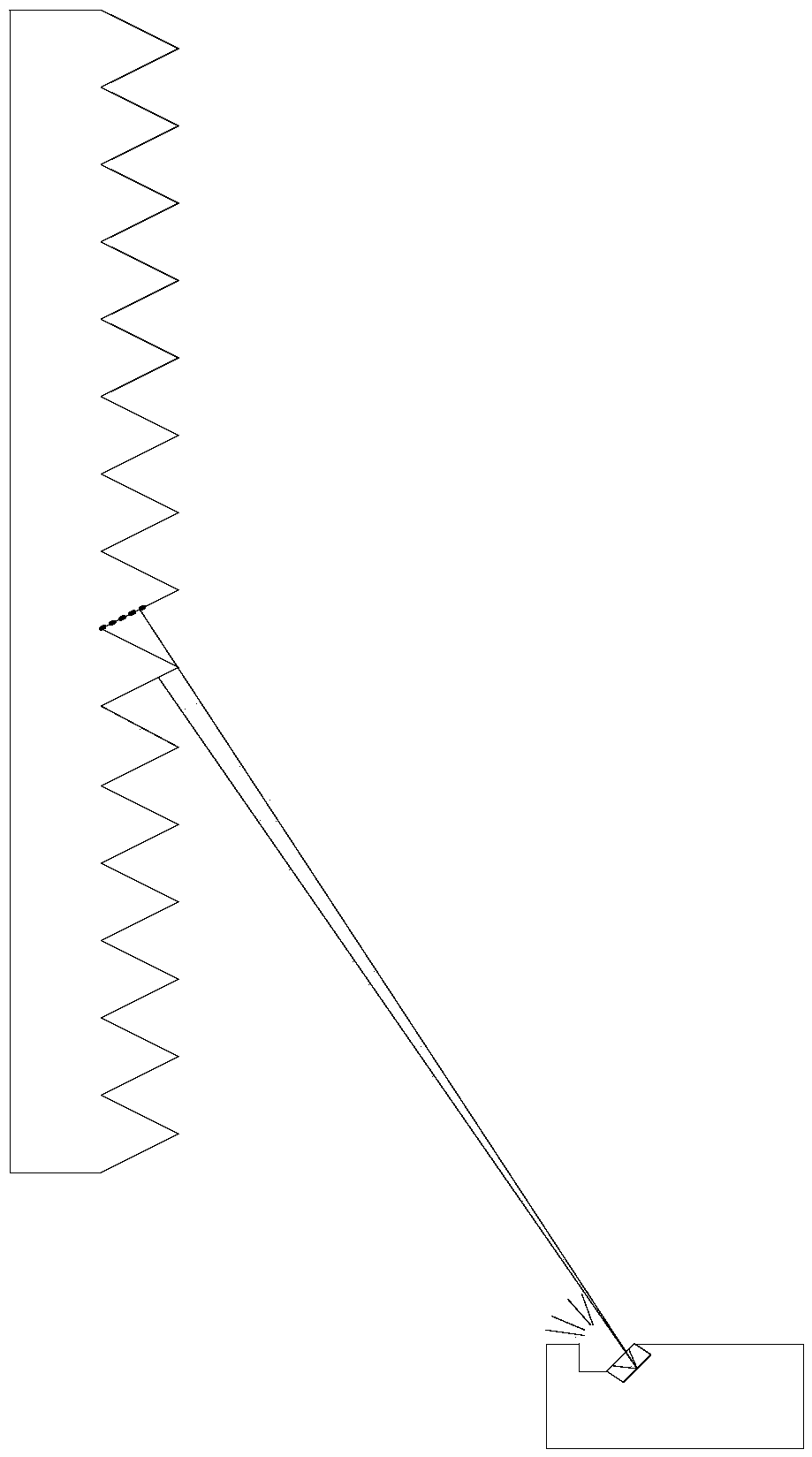

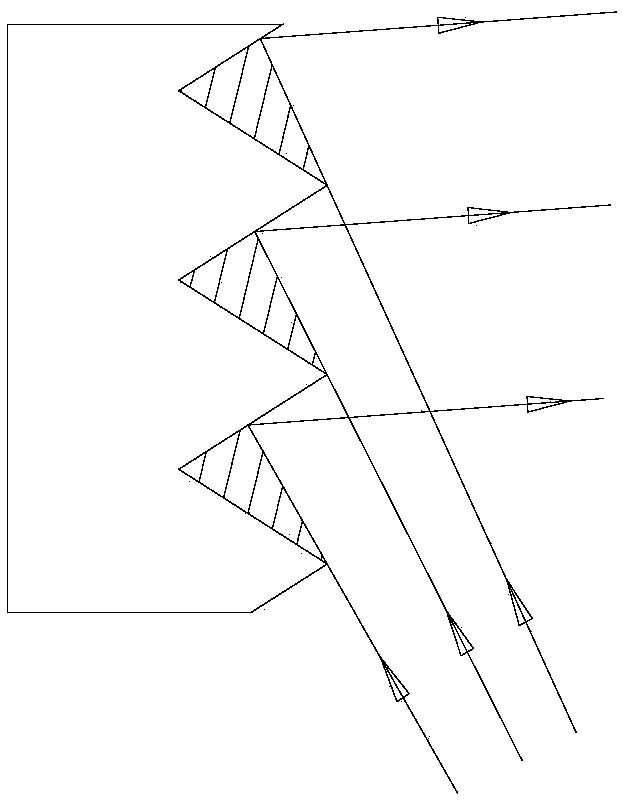

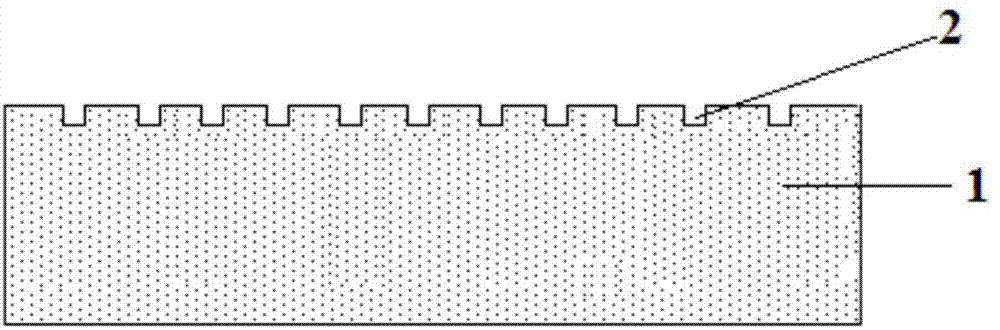

Variable-spacing anti-light curtain and preparation method thereof

PendingCN109634045ASave raw materialsImprove absorption rateProjectorsManufacturing cost reductionPrism

The invention discloses a variable-spacing anti-light curtain and a preparation method thereof. The variable-spacing anti-light curtain comprises a base material layer and a prismatic structure layerarranged on the outer surface of the base material layer, and is characterized in that a plurality of prisms which are parallel to one another in the horizontal direction and have triangular sectionsare arranged on the prismatic structure layer; the distances between the prisms are gradually increased from bottom to top; the upper side surfaces of the prisms are light absorption surfaces; and thelower side surfaces of the prisms are reflective surfaces and are coated with a reflective coating respectively. The distance of the prismatic structure layer in the longitudinal direction of the curtain is adjusted, the distance is gradually increased from bottom to top, the prisms below can be effectively prevented from shielding the prisms adjacent to the prisms above, and the reflecting surfaces of the prisms can completely play a role. According to the structural design, raw materials of the prismatic structure layer are saved, the manufacturing cost is reduced, on the premise that the same reflection area is maintained, the light absorption area is increased, the absorption rate of ambient light is additionally increased, interference of the ambient light is reduced, and the contrast ratio is increased.

Owner:江苏慧智新材料科技有限公司

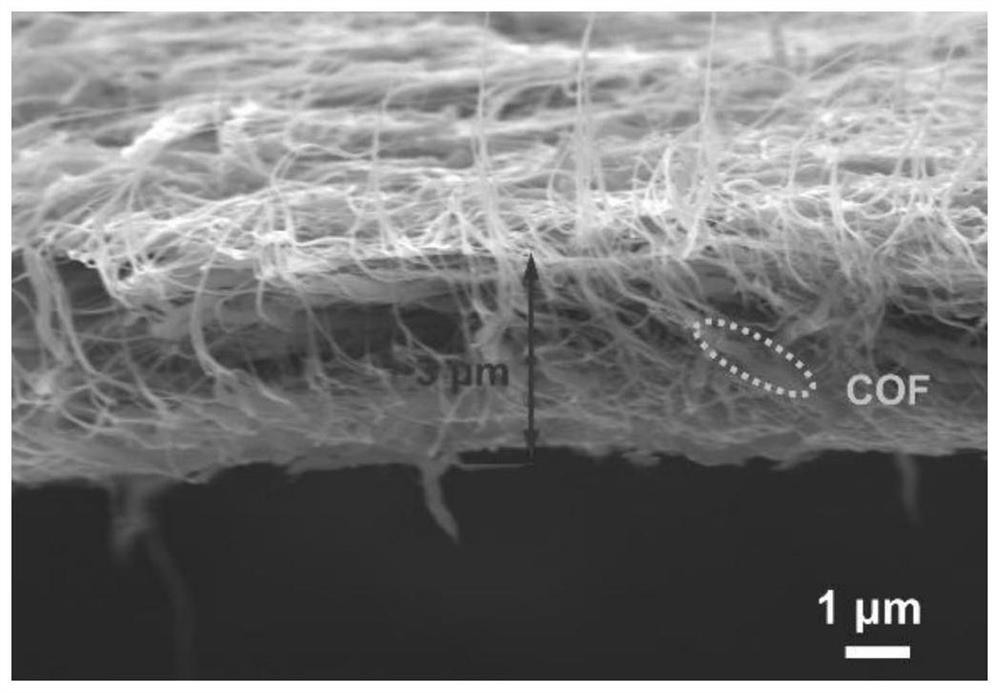

A vulcanized polyacrylonitrile film with hollow tubular nanofibers and a binder-free lithium sulfide battery positive electrode prepared from the film

InactiveCN109192927AIncrease energy densityAlleviate the volume expansion effectMaterial nanotechnologyCell electrodesComposite nanofibersHigh energy

The invention discloses a vulcanized polyacrylonitrile film with hollow tubular nanofibers and a binder-free lithium sulfide battery positive electrode prepared from the film. The process of preparingthe film is as follows: S1, respectively configuring a polyacrylonitrile shell solution and a core layer solution; 2. Prepare composite nanofibers by use coaxial electrospinning technology; S3. The prepared composite nanofiber is washed in solvent, dried and vulcanized to obtain the vulcanized polyacrylonitrile film. A lithium sulfide battery positive electrode is prepare by adopting that nano-fiber in the sulfide polyacrylonitrile film of the invention, which is hollow tubular and has a great specific surface area, without the traditional coat process, and the positive electrode can be fullycontacted with the electrolyte, thereby improving the utilization rate of the electrode; at the same time, sulfide polyacrylonitrile is insoluble in the electrolyte, avoiding the shuttle effect of polysulfide, alleviating the volume expansion effect of the battery, and improving the electrochemical performance of the electrode. The positive electrode of the lithium sulfur battery has a higher energy density and a more stable and lasting cycle life.

Owner:GUANGDONG UNIV OF TECH

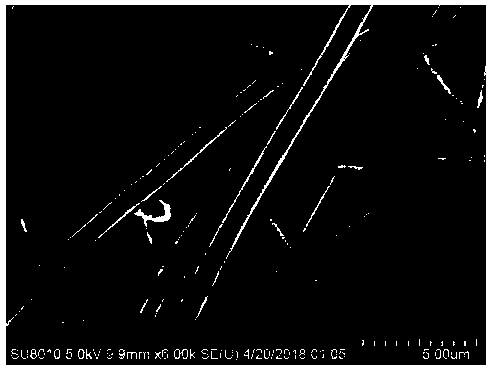

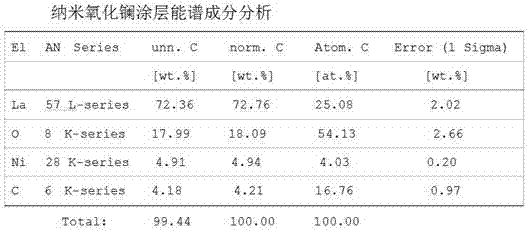

Method for preparing nanometer lanthanum oxide coating on metal carrier

InactiveCN105441999AStrong combinationNot easy to fall offHeterogenous catalyst chemical elementsDispersed particle separationMetal substrateLanthanum

The invention relates to a method for preparing a nanometer lanthanum oxide coating on a metal carrier. The method is characterized in that a lanthanum oxide layer directly grows on a metal substrate through a pulse electrochemical deposition method, and the thickness of the deposition layer is adjustable within the range of 1-50 microns. The prepared lanthanum oxide deposition layer is of a nanometer flaky structure, and the thickness is 5-20 nm. The specific surface area of the deposition layer is large and has a high bonding capacity with the substrate, and the effect is better than a common coating process. Therefore, the method for preparing the nanometer lanthanum oxide coating on the metal carrier has high practical value.

Owner:CHINA FIRST AUTOMOBILE

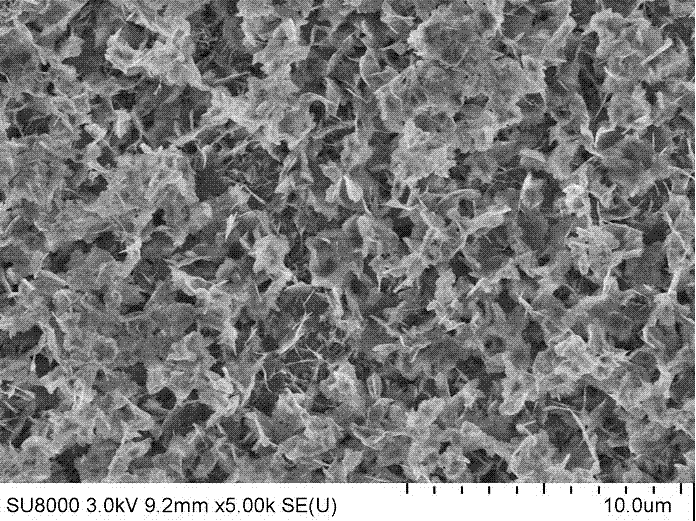

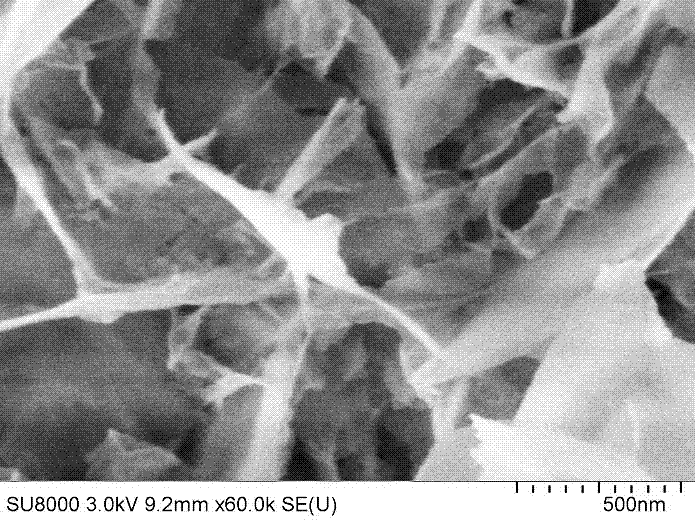

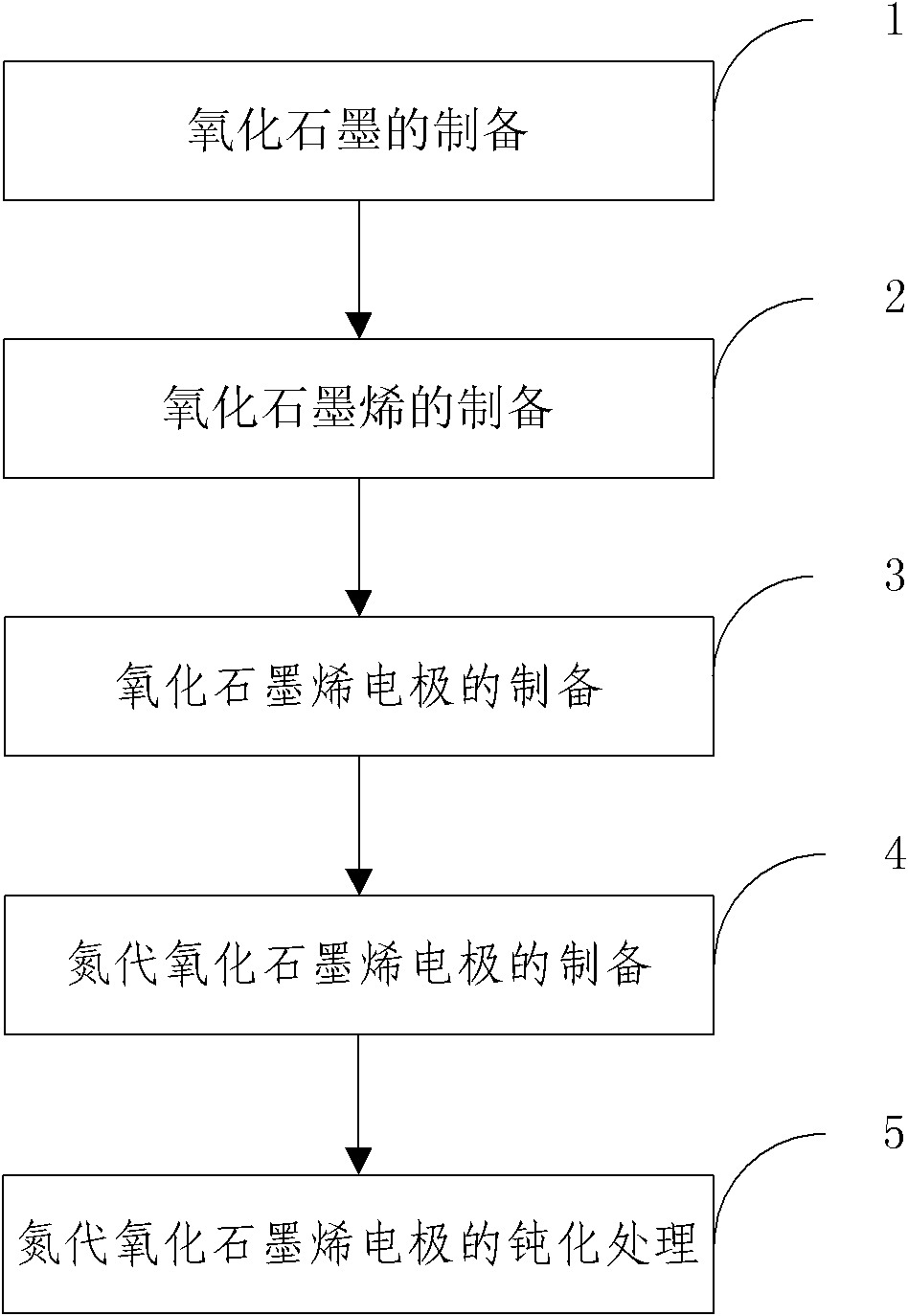

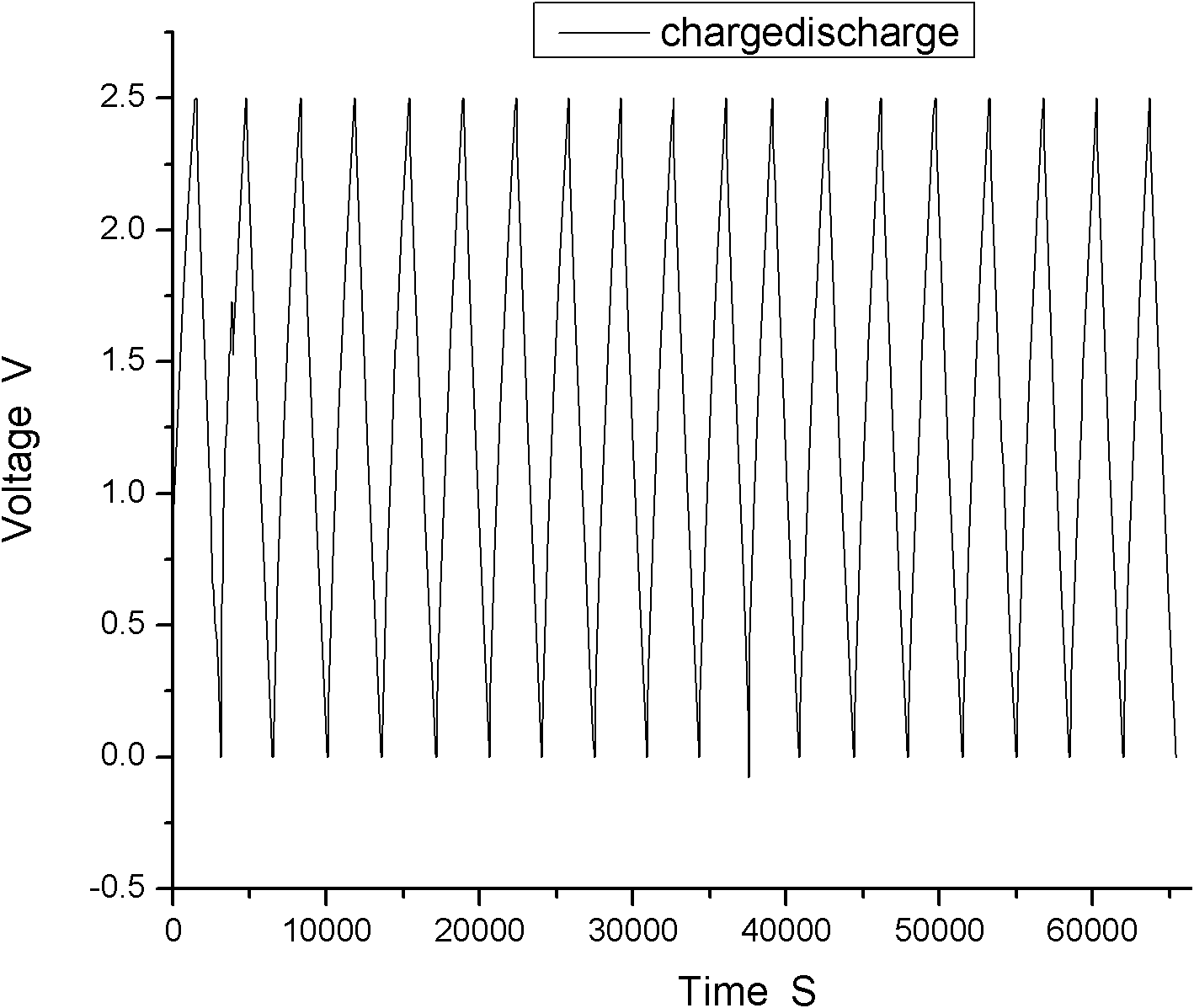

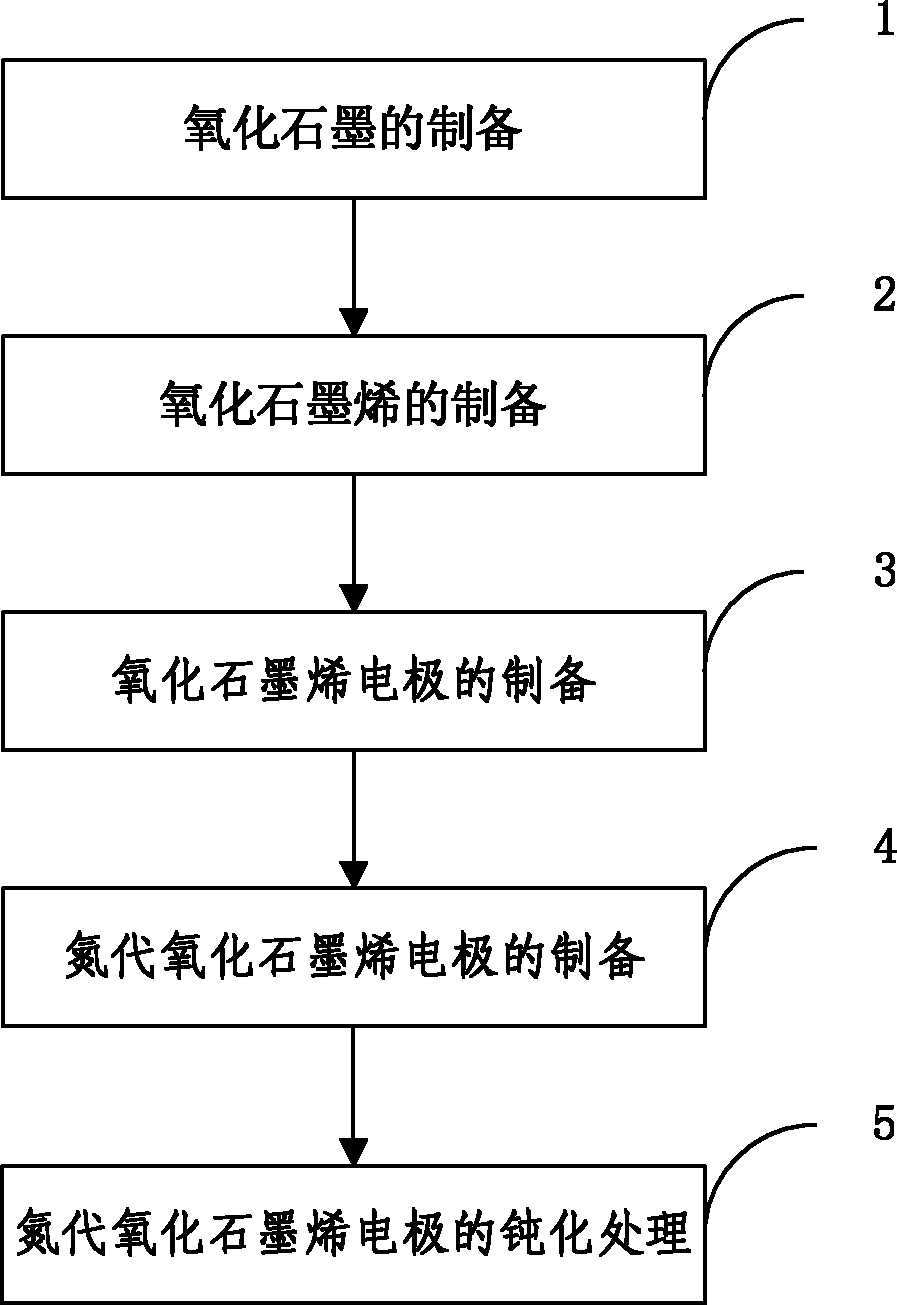

Nitride substituted graphene oxide electrode and preparation method thereof

ActiveCN102610793AReduce processing complexitySimple technologyCell electrodesGraphene electrodeElectrochemistry

The invention belongs to the field of electrochemistry energy sources, and discloses a nitride substituted graphene oxide electrode and a preparation method thereof. The preparation method of the electrode comprises the following steps: adding graphene oxide into a container which is filled with water and the bottom of which is provided with a metal concentrate body, stirring, then standing and carrying out deposition treatment, then taking out the metal concentrate body of the concentrate graphene oxide and drying, thereby obtaining the graphene oxide electrode; and placing the graphene oxide electrode in a reactor, and then introducing the mixed gas of ammonia and argon to the reactor for substitution reaction, thereby obtaining the nitride substituted graphene oxide electrode. The preparation method of the nitride substituted graphene oxide electrode provided by the invention is simple in preparation process, and parameters can be controlled; the application cost is low, and the using is wide; and meanwhile, the normally used coating technology used in the prior art is omitted, fluorination is realized by one step in the process of preparing the electrode sheet, and multiple complex flows in the material fluorination process are omitted.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

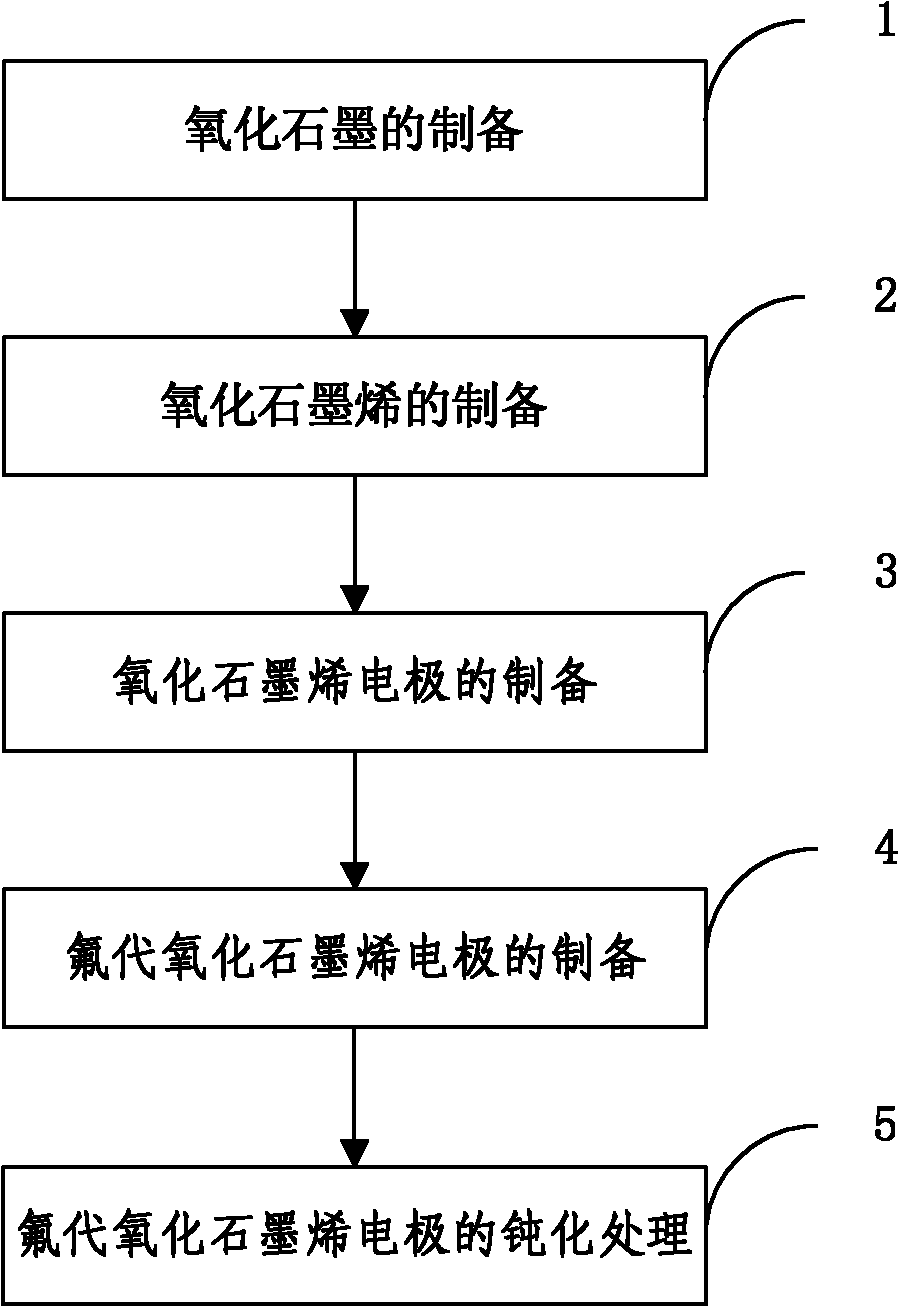

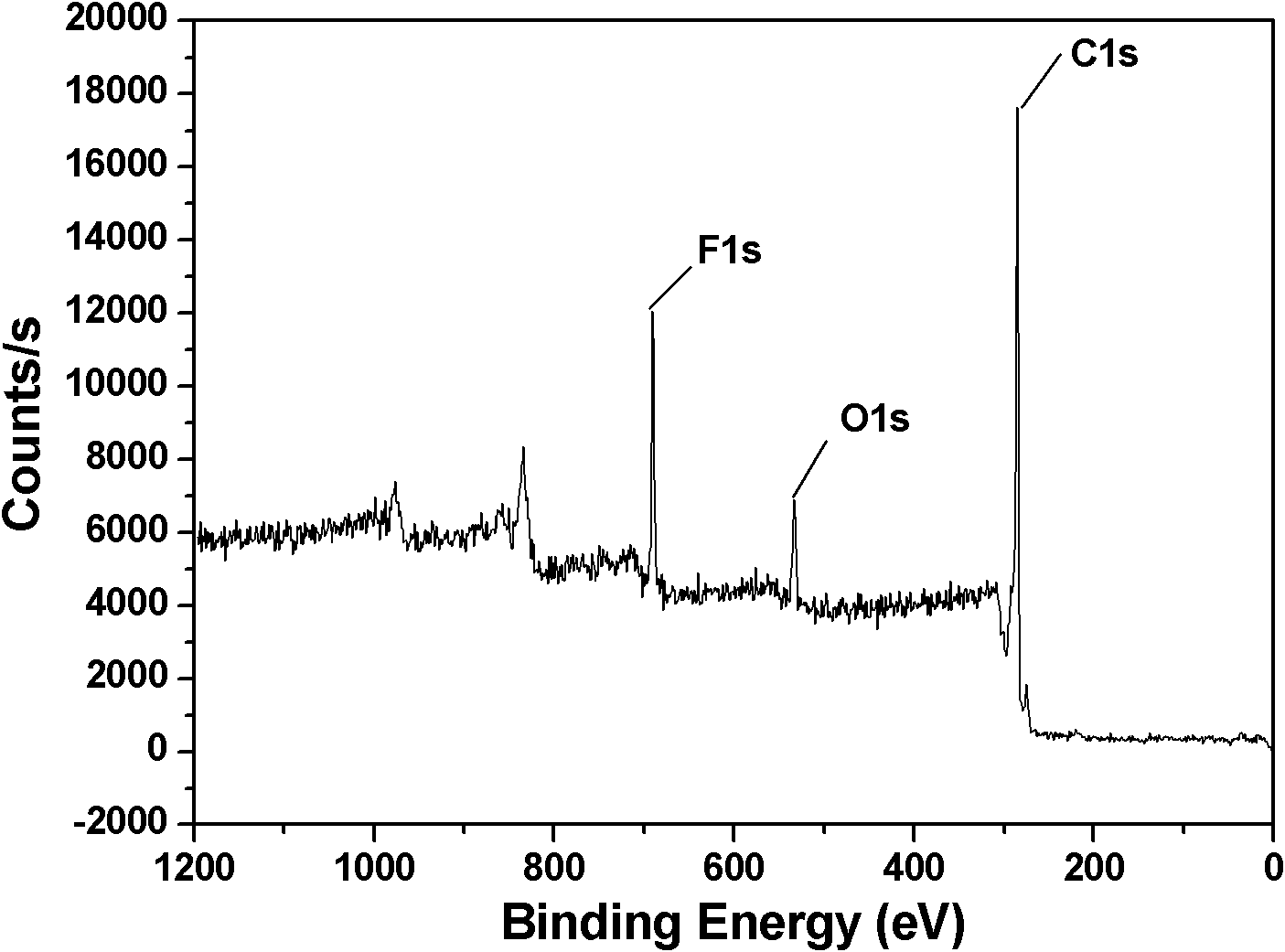

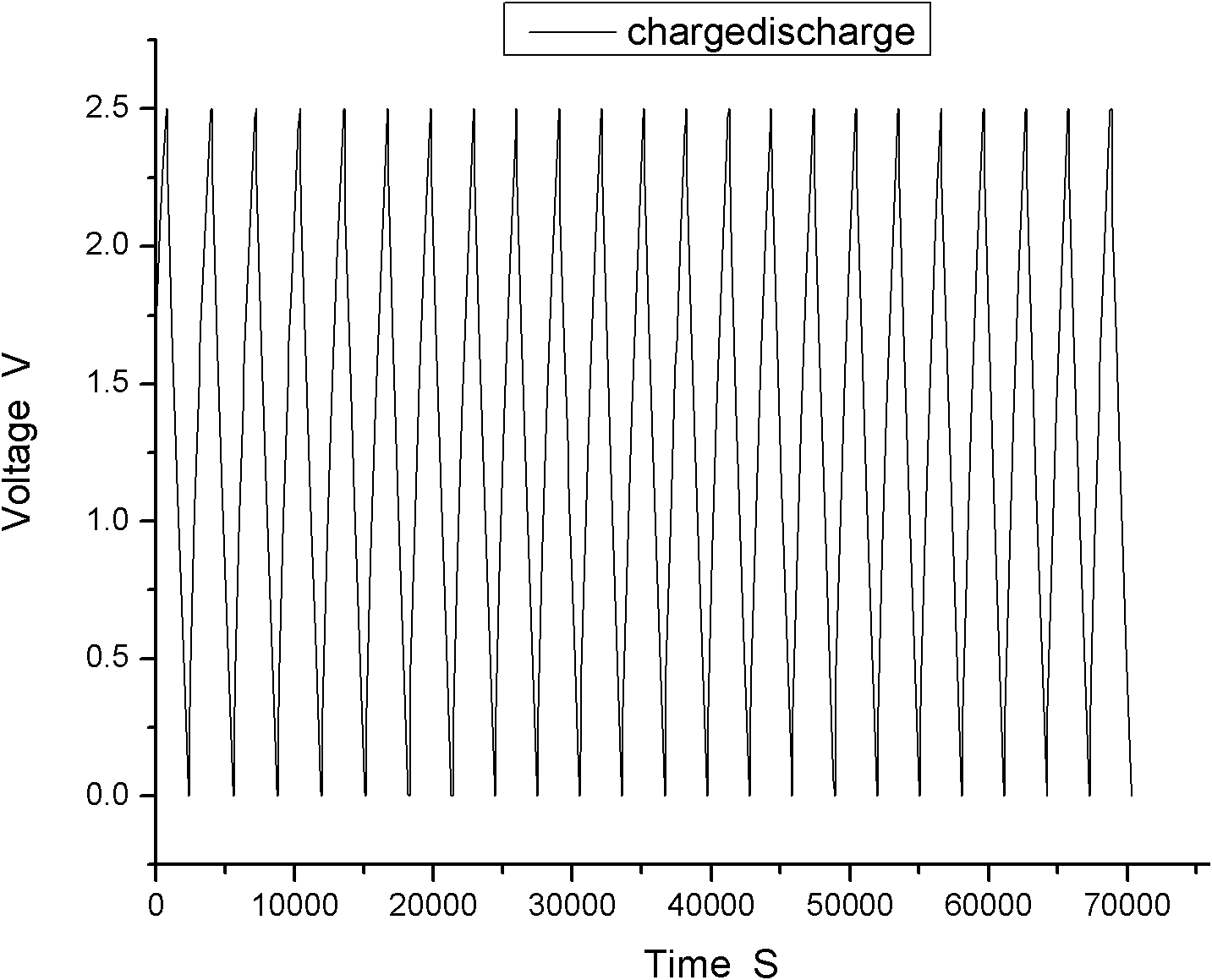

Fluoro graphene oxide electrode and preparation method thereof

ActiveCN102610794ASimple technologyOptimizing Control ParametersElectrolytic capacitorsCell electrodesGraphene electrodeNitrogen gas

The invention discloses a fluoro graphene oxide electrode and a preparation method thereof, belonging to the field of electrochemical energy sources. The preparation method of the fluoro graphene oxide electrode comprises the following steps of: adding graphene oxide to a container, stirring, standing, depositing, then taking out metal concentrates concentrating the graphene oxide to dry to prepare a graphene oxide electrode; and adding the graphene oxide electrode into a reactor, and following charging mixed gas of fluorine and nitrogen into the reactor to carry out a substitution reaction to manufacture the fluoro graphene oxide electrode. The preparation method of the fluoro graphene oxide electrode, disclosed by the invention, has the advantages of simple technical skill, controllable parameters, low implementation cost and wide application; in addition, a common coating process at the present stage is saved, fluorination is implemented in an electrode plate manufacturing process once, and multiple complex flows in a material fluorination process are saved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

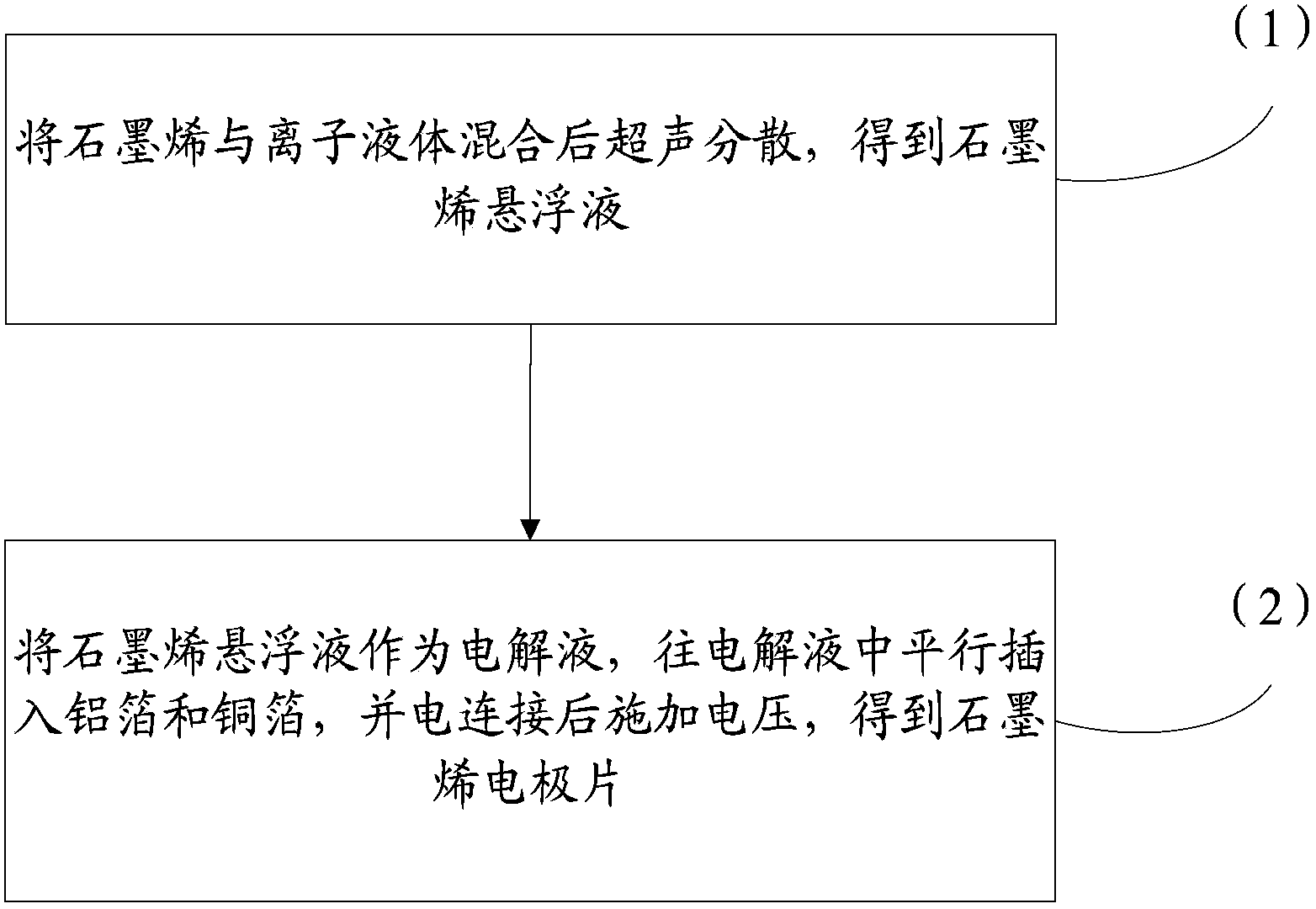

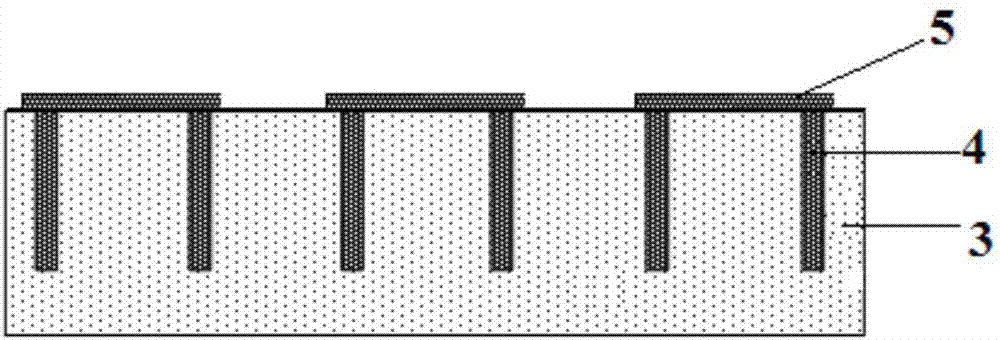

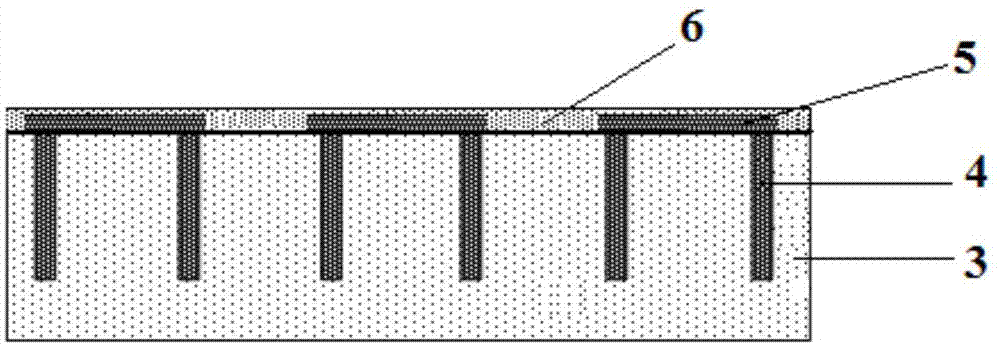

Graphene electrode plate and preparing method thereof

InactiveCN103903878AChange compatibilityIncrease capacityHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneIon

The invention discloses a graphene electrode plate and a preparing method thereof. The method comprises the following steps: graphene and ionic liquid are mixed and then subjected to the ultrasonic dispersion process to obtain stable graphene suspending liquid; and the graphene suspending liquid is used as an electrolyte, two aluminum foils or copper foils which are made from a same material are inserted into the electrolyte in parallel as an anode electrode and a cathode electrode separately, a voltage is applied after electrical connection, and the cathode electrode is taken down to obtain the graphene electrode plate. According to the preparing method provided in the invention, grapheme can be better dispersed by using the ionic liquid, and the ionic liquid exists between layers of the deposited graphene, so the compatibility between the graphene and the electrolyte can be changed, and the capacity can be improved; according to the electrode plate prepared through the electro-deposition method, the complex coating process can be omitted, the process is simple, and binder does not need to be used, so the contact resistance between a current collector and an active material layer can be effectively reduced so as to reduce the equivalent series resistance of a supercapacitor, and improve the power density finally.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Wafer temporary bonding method

ActiveCN103794523AReduce manufacturing costIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyEngineering

The invention discloses a wafer temporary bonding method. The method includes the steps that a silicon through hole and front face manufacturing technology of a wafer is completed; the front face of the wafer is coated with temporary bonding glue; the surface of a supporting piece is roughened; the roughened surface of the supporting piece is bonded with the front face, coated with the temporary bonding glue, of the wafer; the back face of the wafer bonded with the supporting piece is thinned until the thickness of the wafer reaches a needed value; a back face manufacturing technology of the wafer after the back face is thinned is finished; the temporary bonding glue on the wafer after the back face manufacturing technology is removed. According to the method, due to the fact that the surface of the supporting piece is roughened, the contact area between the temporary bonding glue and the supporting piece is increased, and the temporary bonding glue is nested and fixed and prevented from sliding and offsetting at high temperature.

Owner:TSINGHUA UNIV

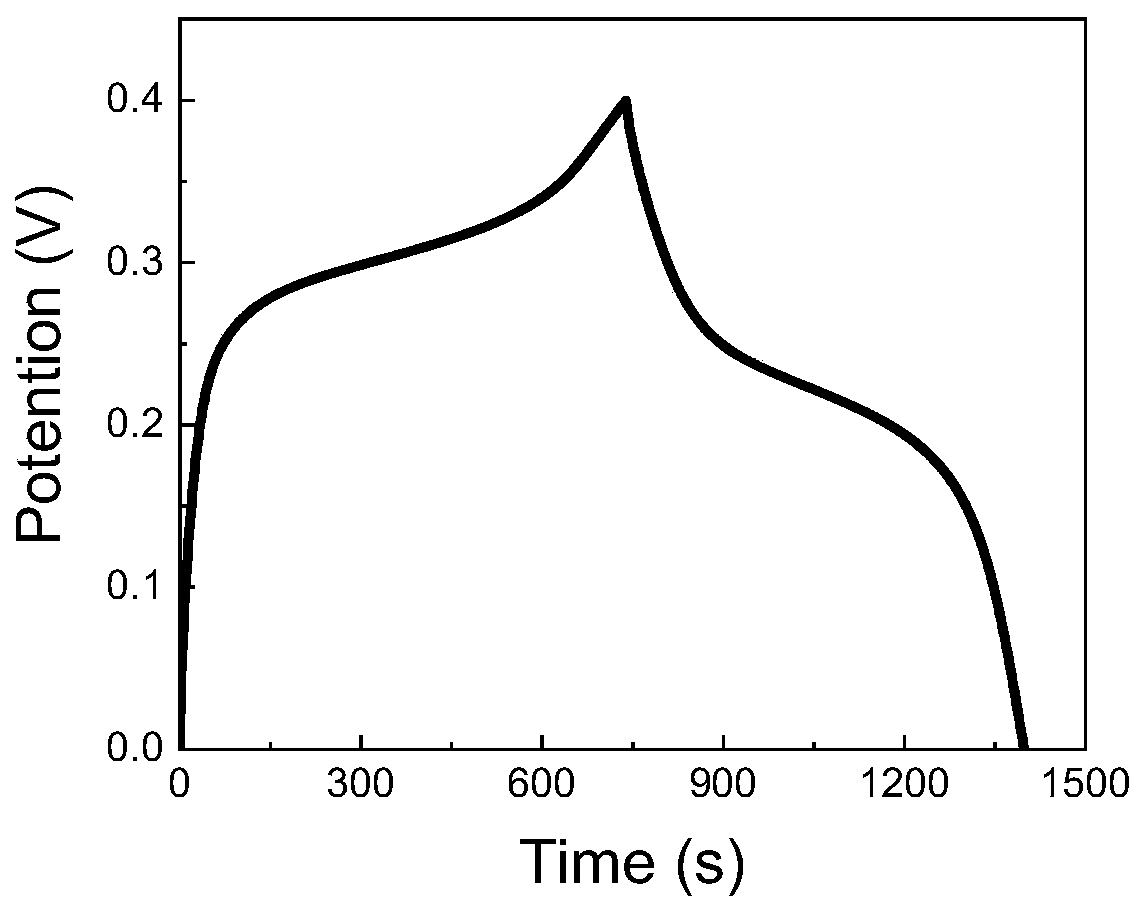

Preparation method of asymmetric supercapacitor based on prussian blue analog/reduced graphene thin film

InactiveCN108847356AIncrease capacitanceRich varietyHybrid capacitor electrodesHybrid/EDL manufactureComposite filmFiltration

The invention discloses a preparation method of an asymmetric supercapacitor based on a prussian blue analog / reduced graphene thin film. The preparation method comprises the following steps of preparing graphene oxide on the basis of a Hummers method, preparing reduced graphene, preparing prussian blue analog with different central metal atoms, and preparing a reduced graphene dispersion liquid and a prussian blue analog dispersion liquid; adopting a vacuum suction filtration method for preparing a composite thin film with the reduced graphene and prussian blue analog with a layer-by-layer stacking structure; and finally, by taking the prepared reduced graphene and prussian blue analog composite thin film as positive and negative materials, preparing the asymmetric supercapacitor. The prepared prussian blue analog / graphene composite material thin film prepared by the method has the layer-by-layer stacking structure, so that the problem that a graphene-based electrode is easily stackedin the preparation process is solved; the advantages of graphene and prussian blue analog are combined, so that a better synergistic effect can be generated; and meanwhile, the preparation method is simple and low in cost.

Owner:SHANGHAI JIAO TONG UNIV

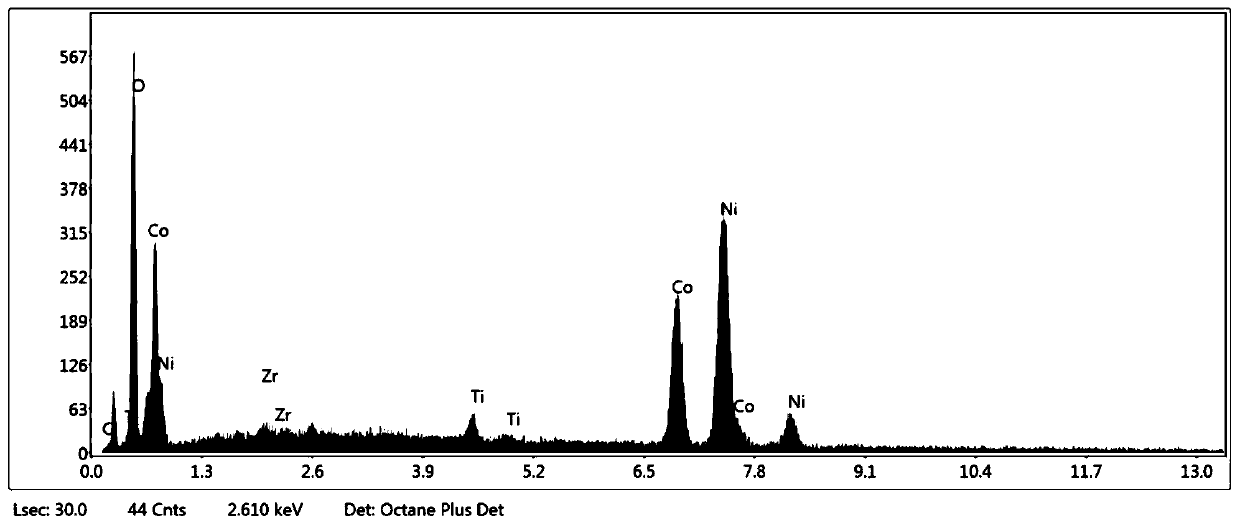

Preparation method of active nano porous nickel/nickel oxide load ultra-thin nickel cobaltate nanosheet flexible electrode material

ActiveCN110379648AHighlight substantiveHighlight substantive featuresMaterial nanotechnologyHybrid capacitor electrodesUltra fineAlloy

The invention relates to a preparation method of an active nano porous nickel / nickel oxide load ultra-thin nickel cobaltate nanosheet flexible electrode material. The method is characterized in that nano porous nickel prepared by natural dealloying is utilized as a template, through three-electrode electrochemical deposition, an ultra-thin ultra-fine nickel cobaltate nanosheet is grown on a surface of the nanoporous nickel and then heated to obtain the ultrathin nickel cobaltate nanosheet flexible electrode material. The method is advantaged in that firstly, the nickel cobaltate nanosheet is constructed on the surface of the nano porous template, close combination of the nickel cobaltate nanosheet and nano pores is achieved, and improvement of cycle stability is facilitated; the prepared nickel cobaltate nanosheet is ultra-thin and ultra-fine, has thickness of only 10-20 nm, has a larger effective specific surface area when participating in electrode reaction, has more active sites andrepresents better electrochemical performance.

Owner:HEBEI UNIV OF TECH

Preparation process of color ink-jet printing photographic paper

ActiveCN107604754AGood ink absorptionHigh glossCoatings with pigmentsSpecial paperPhotographic paperProcessing cost

The invention discloses a preparation process of a color ink-jet printing photographic paper. The process includes the steps of: (1) photographic paper surface treatment, (2) ink absorption layer preparation, and (3) gloss layer preparation. The invention perform reasonable optimization treatment on the existing printing photographic paper preparation technology, eliminates the prime paint coatingprocedure in the original technology, lowers the process complexity, and reduces adding of chemical paints. The preparation process provided by the invention is conducive to lowering the processing cost and reducing the paper thickness, and under the cooperation of the steps together, and the finally prepared printing photographic paper has enhanced ink absorption, glossiness, light resistance, folding resistance and the like, and good comprehensive usage quality, thus having substantial market competitiveness.

Owner:安徽文峰新材料科技股份有限公司

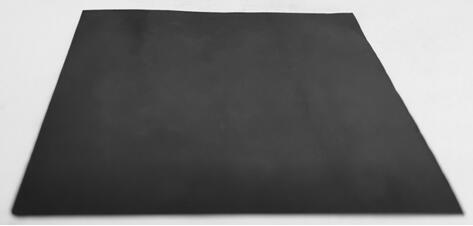

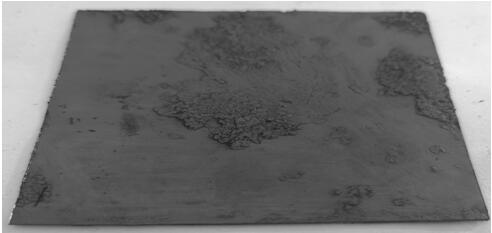

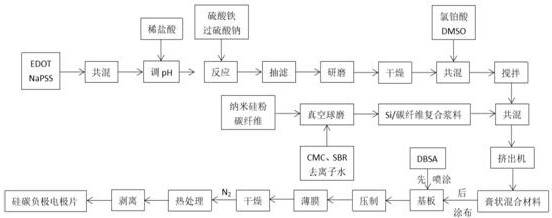

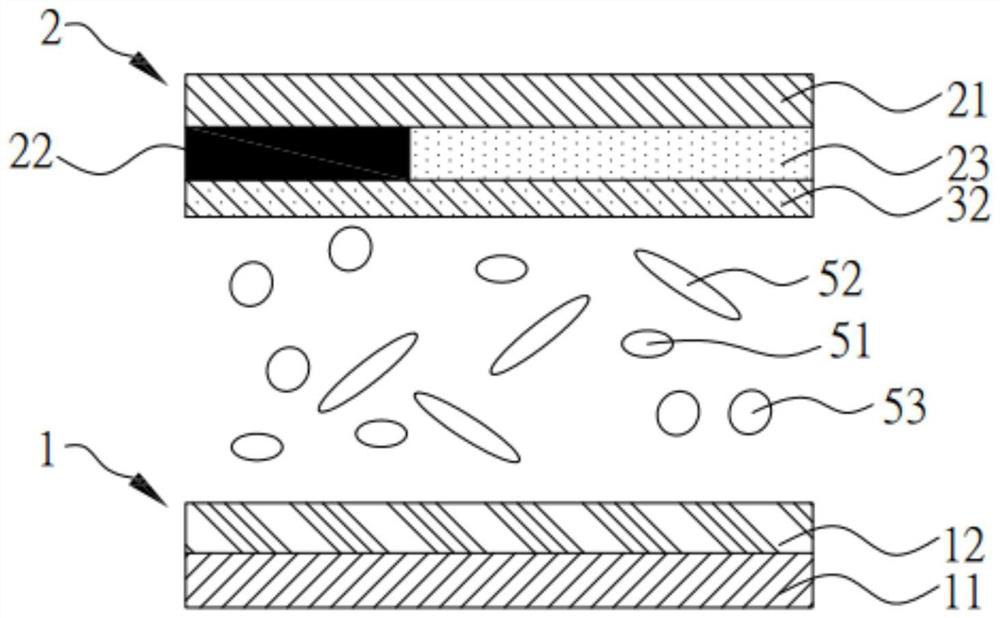

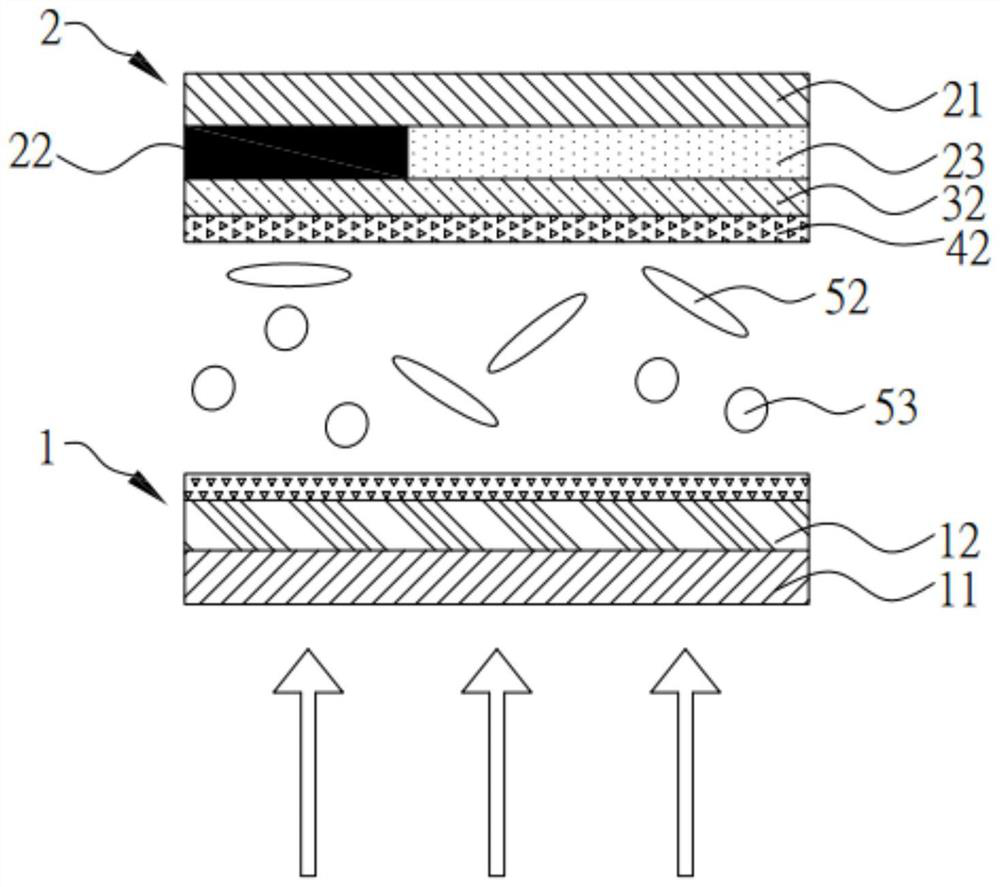

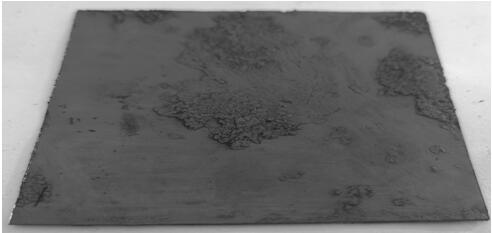

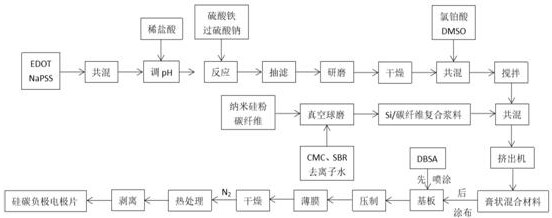

Method for preparing silicon-carbon negative electrode plate by extrusion and calendering and electrode plate

ActiveCN112151768AHigh strengthGood compatibilityElectrode rolling/calenderingSecondary cellsFiberMetal foil

The invention relates to the technical field of battery pole pieces, in particular to a method for preparing a silicon-carbon negative electrode plate by extrusion and calendering, which comprises thefollowing steps: mixing PEDOT:PSS, chloroplatinic acid and dimethyl sulfoxide to obtain modified PEDOT:PSS slurry; mixing nano silicon powder, carbon fibers, sodium carboxymethyl cellulose, styrene-butadiene rubber emulsion with the mass concentration of 30% and deionized water to obtain silicon powder / carbon fiber composite slurry; stirring and extruding the PEDOT:PSS slurry and the silicon powder / carbon fiber composite slurry to obtain paste; and carrying out blade coating on the paste to form a film. According to the invention, the problems of peeling and cracking of the silicon-carbon negative electrode plate in the prior art are solved. According to the preparation method, the flexible PEDOT:PSS thin film is adopted to replace an existing metal foil, and the negative electrode material is directly loaded on an electrode plate, so that the problem of poor compatibility between the negative electrode active material and the electrode plate in a traditional coating process is avoided. The preparation method is simple and controllable in process and suitable for large-scale and continuous production.

Owner:上海鲸孚科技有限公司

LED vacuum packaging process and vacuum pressing device

ActiveCN111640840AUniform excitation light colorGood appearance consistencySolid-state devicesSemiconductor devicesWaferingFluorescence

The invention discloses an LED vacuum packaging process, which comprises the steps of (1) carrying out die bonding on a substrate; (2) pressing the edge of a fluorescent soft film on the substrate ina vacuum environment, wherein the part, which is positioned on the inner side of the pressed edge, of the fluorescent soft film is not pressed, and a wafer mounting area is formed between the substrate and the fluorescent soft film; and (3) unloading vacuum. By adopting the technical scheme, the substrate after die bonding is put into a vacuum pressing device for vacuum pressing of the fluorescentsoft film, only the periphery of the fluorescent soft film is in press fit with the substrate, and the wafer mounting area at the middle position forms a vacuum cavity, so that after the substrate ismoved out of the vacuum cavity, the fluorescent soft film is tightly pressed on the wafer and the substrate under the action of external pressure, the fluorescent film uniformly covers the surface ofthe wafer, the appearance consistency is good, the excitation light color is more uniform, the original coating and dispensing processes are also omitted, and the production efficiency is greatly improved. In addition, the invention further provides a corresponding vacuum pressing device.

Owner:HONGLI ZHIHUI GRP CO LTD

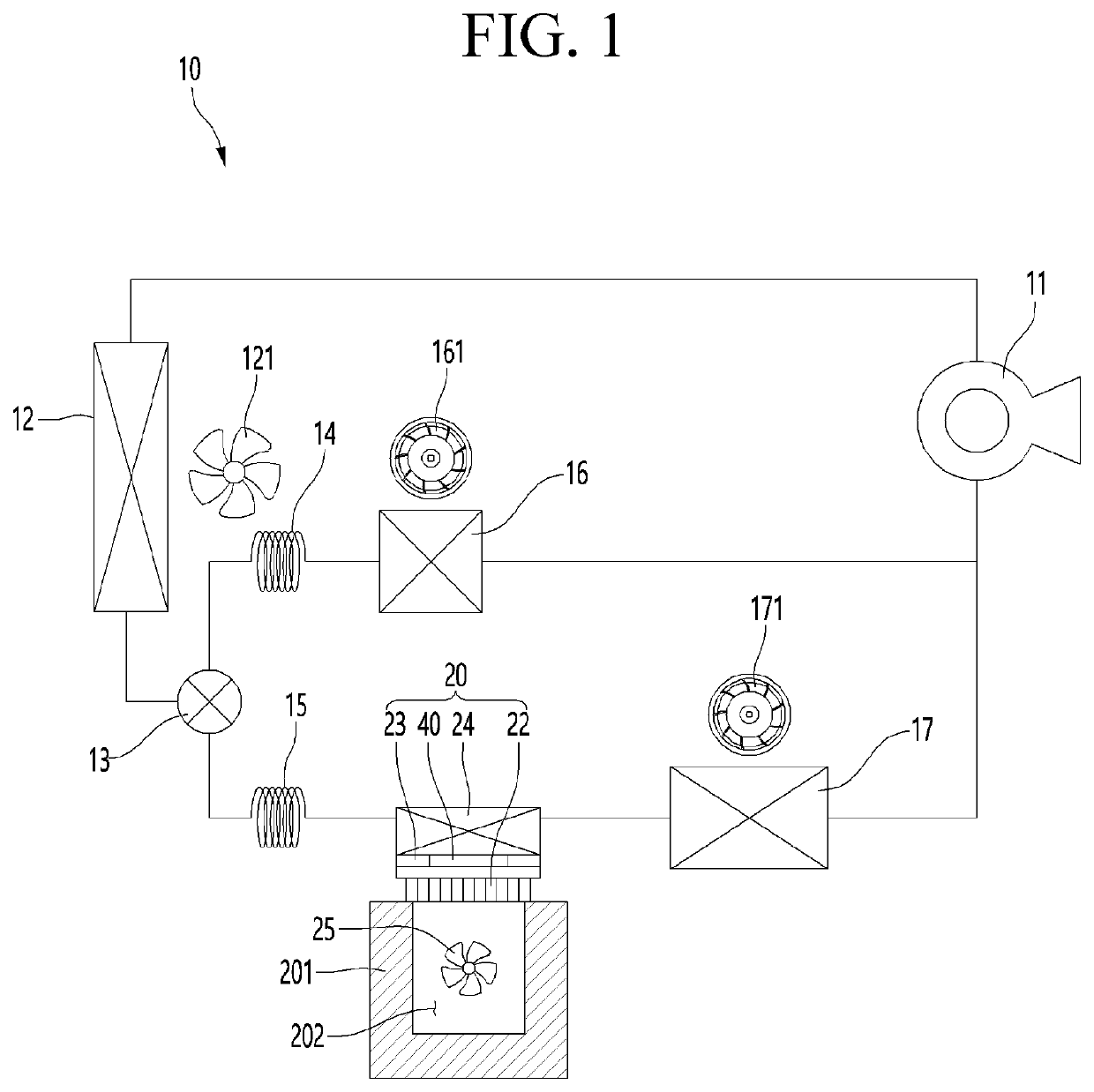

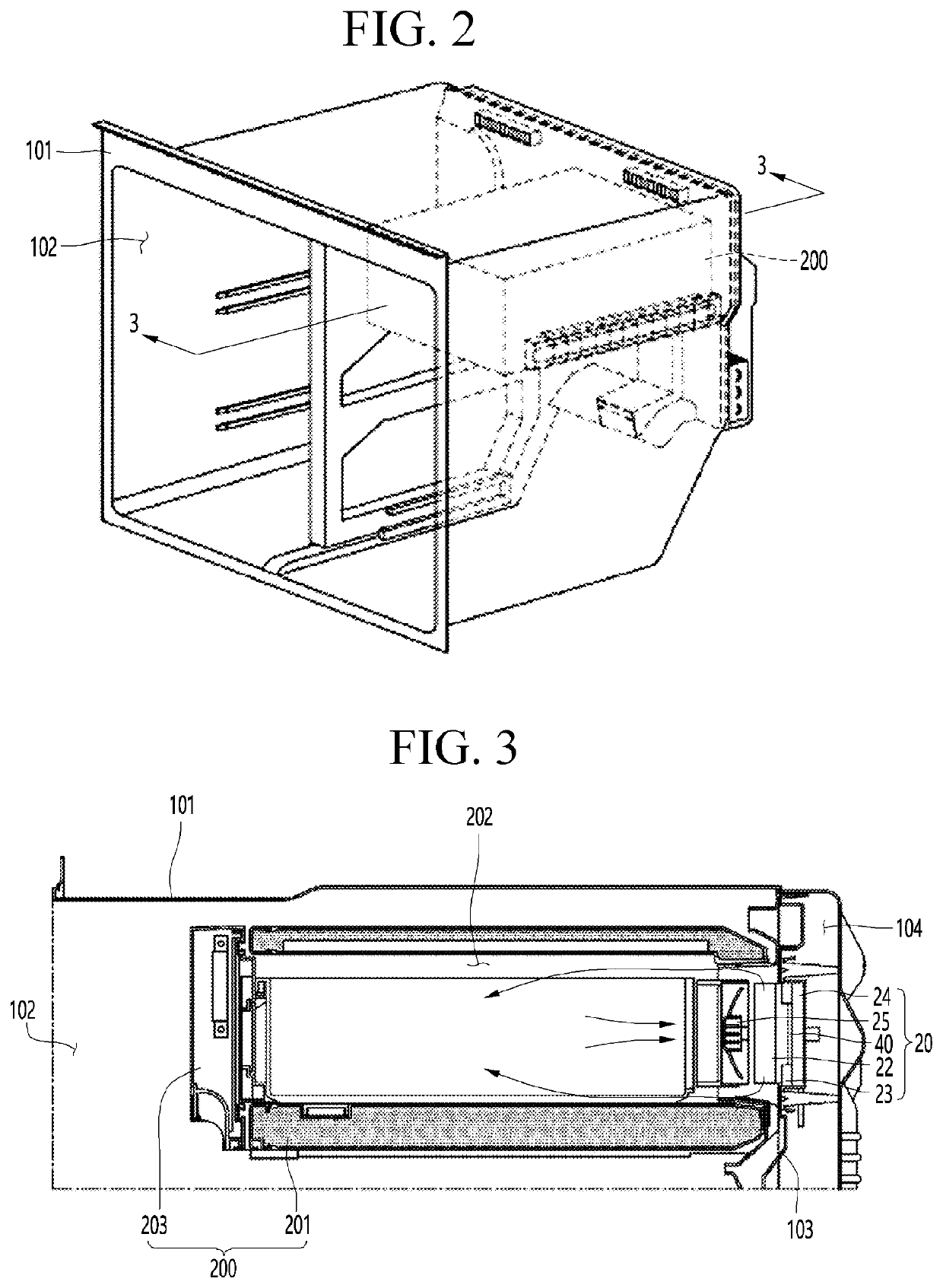

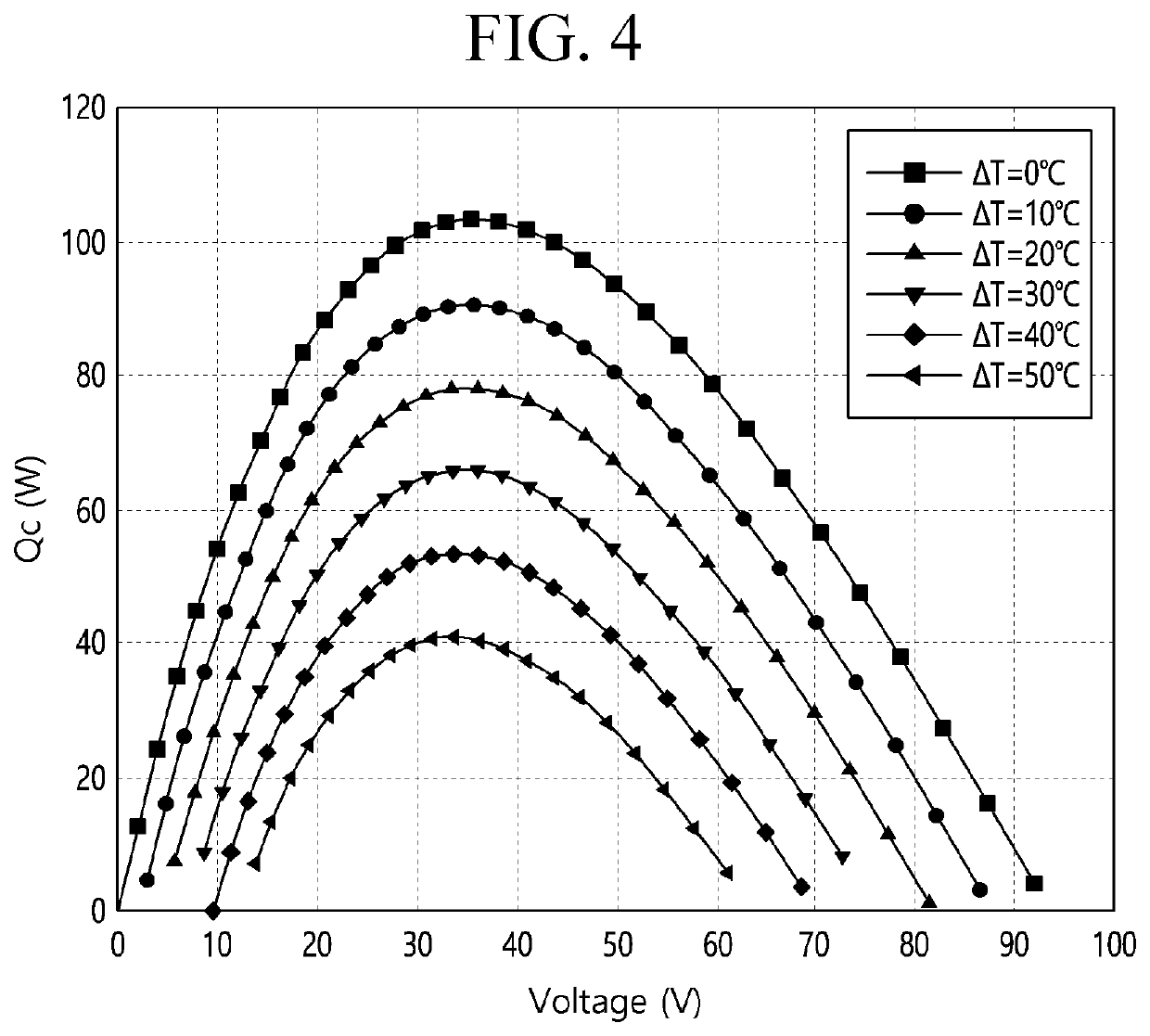

Thermoelectric module and refrigerator comprising same

PendingUS20220238777A1Reduce thicknessImprove stabilityMechanical apparatusThermoelectric device with peltier/seeback effectIceboxEngineering

A thermoelectric module according to an embodiment of the present invention may comprise: a cold sink; a thermoelectric element having a heat absorption surface coupled to the cold sink; a heat sink coupled to a heating surface of the thermoelectric element to dissipate heat transferred from the cold sink to the outside of the thermoelectric element; and a sealing cover for connecting the edge of the cold sink and the edge of the heat sink to surround the thermoelectric element, wherein the cold sink, the heat sink, and the thermoelectric element may be integrally formed by the sealing cover.In addition, the thermoelectric element may be a cascade type thermoelectric element in which two thermoelectric elements having the same or different specifications are coupled to each other.

Owner:LG ELECTRONICS INC

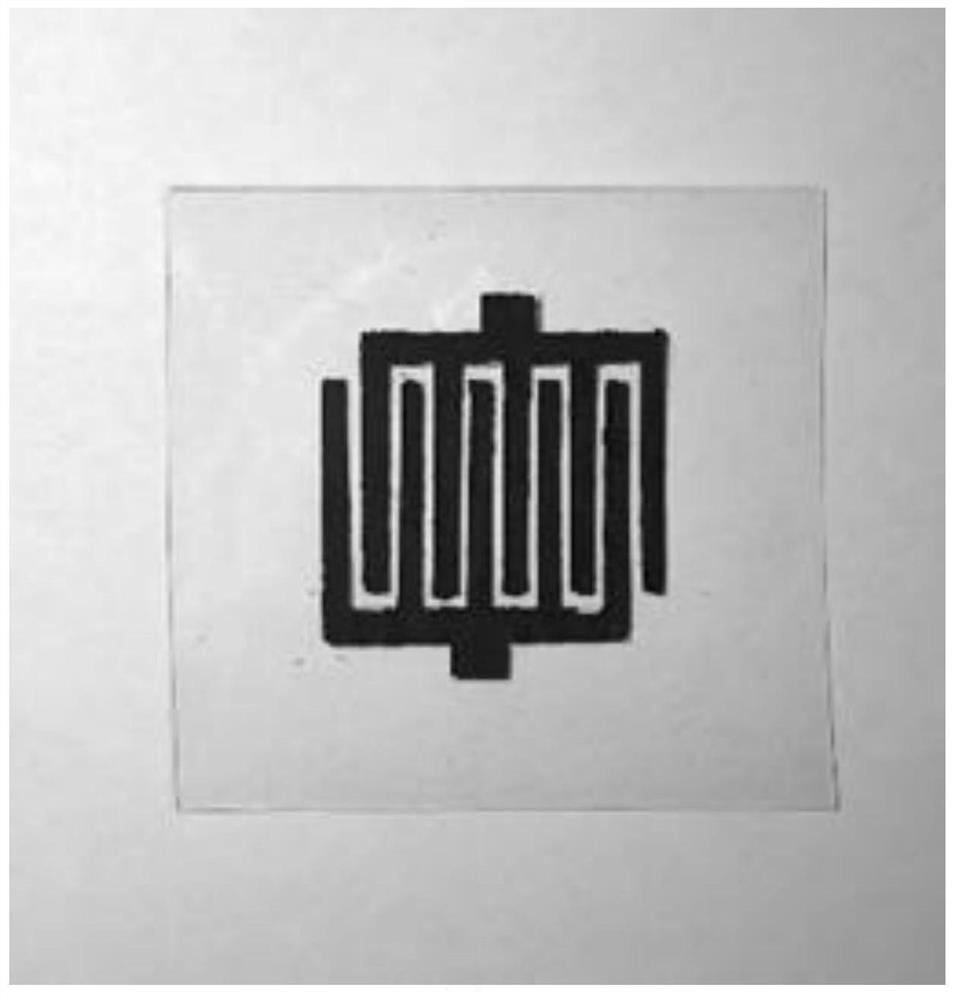

A preparation method of thin-film electrodes based on covalent organic framework materials

ActiveCN110164716BEasy to operateReduce spacingHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceThin film electrode

The invention discloses a preparation method of a thin film electrode based on a covalent organic frame material, and relates to the field of material preparation. The method comprises the following steps: firstly a nitrogen-rich covalent organic frame material with fully conjugated carbon-carbon double bonds is synthesized; then the prepared covalent organic frame material and the commercializedsingle-walled carbon nanotube are dispersed by N, N-dimethylformamider to obtain a dispersion; then the dispersion is added to an electrode template and the thin film electrode is obtained by vacuum pumping and filtering; and finally the obtained thin film electrode is transferred to a flexible substrate, and vacuum drying is performed so as to obtain a flexible electrode which can be used for manufacturing a flexible micro supercapacitor. The preparation method has the advantages of easy operation, simple equipment and large-scale preparation. The shape of interposer finger is applied to makethe electrode spacing as small as possible and the device as miniaturized as possible; and the specific area capacitance can be up to 15.2 mF.cm<-2> so as to have great application potential in supercapacitors.

Owner:SHANGHAI JIAOTONG UNIV

A kind of graphene/carbon nanotube/nickel electrode, its preparation method and application

ActiveCN102760582BEasy to insertThe effect of complementary performance is goodElectrolytic capacitorsCell electrodesGraphite carbonElectrophoreses

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of wafer temporary bonding method

ActiveCN103794523BIncrease profitIncrease contact areaSemiconductor/solid-state device manufacturingManufacturing technologyWafer bonding

The invention discloses a wafer temporary bonding method. The method includes the steps that a silicon through hole and front face manufacturing technology of a wafer is completed; the front face of the wafer is coated with temporary bonding glue; the surface of a supporting piece is roughened; the roughened surface of the supporting piece is bonded with the front face, coated with the temporary bonding glue, of the wafer; the back face of the wafer bonded with the supporting piece is thinned until the thickness of the wafer reaches a needed value; a back face manufacturing technology of the wafer after the back face is thinned is finished; the temporary bonding glue on the wafer after the back face manufacturing technology is removed. According to the method, due to the fact that the surface of the supporting piece is roughened, the contact area between the temporary bonding glue and the supporting piece is increased, and the temporary bonding glue is nested and fixed and prevented from sliding and offsetting at high temperature.

Owner:TSINGHUA UNIV

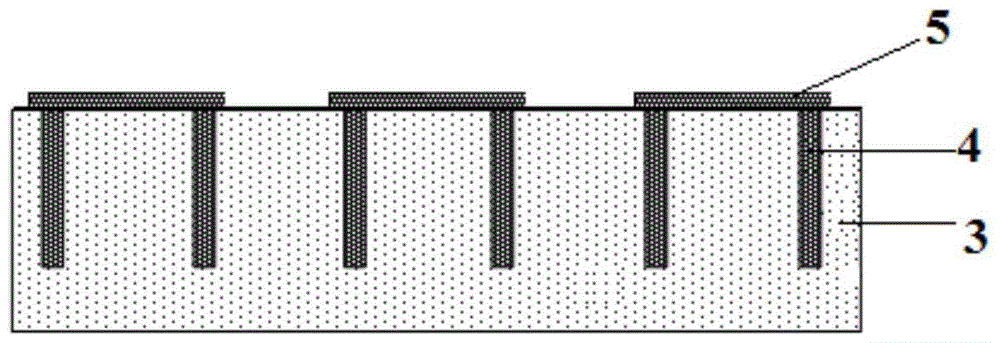

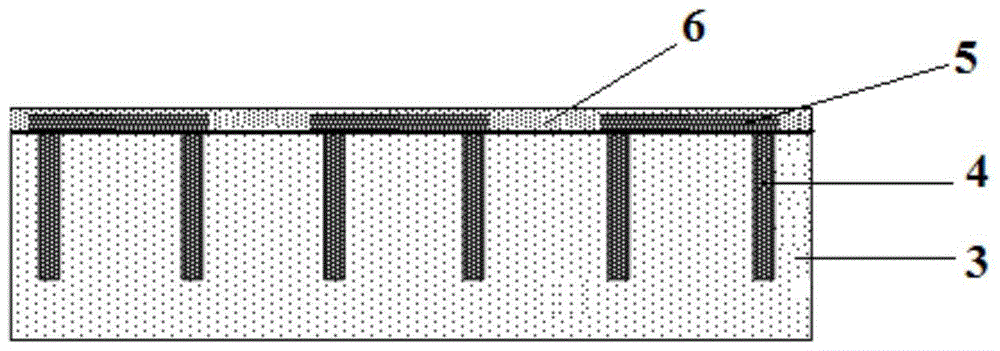

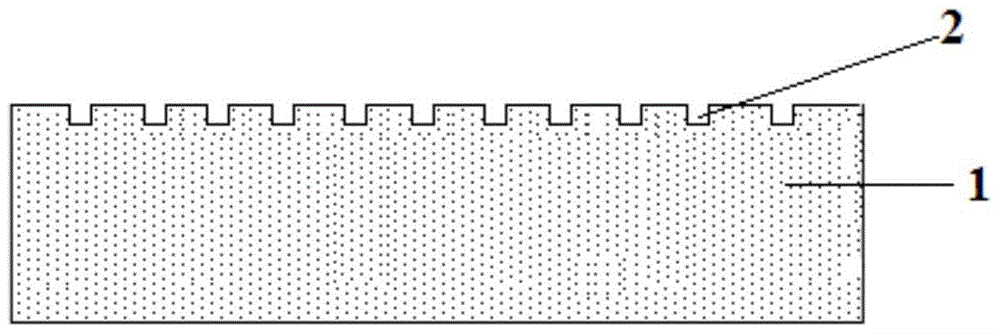

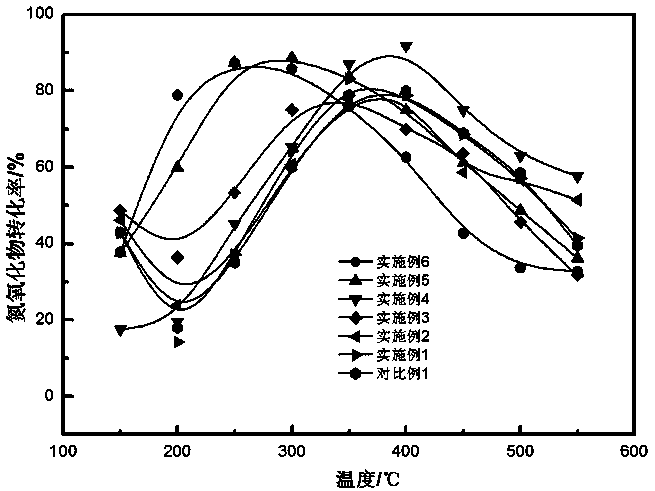

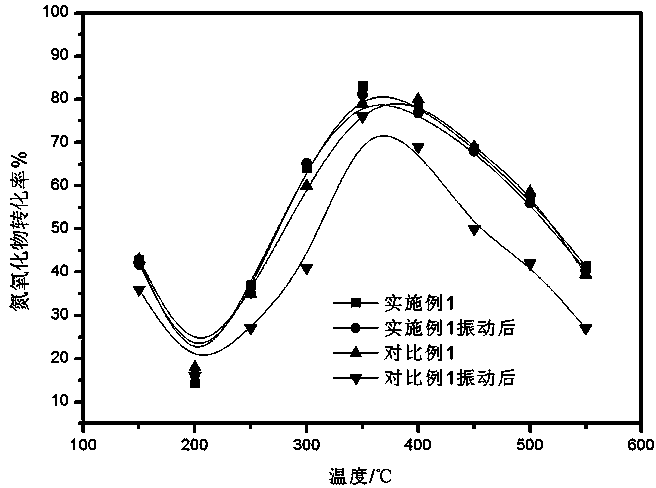

A kind of preparation method of monolithic molecular sieve SCR catalytic reactor

ActiveCN107362822BIncreased durabilityNo downside of sheddingMolecular sieve catalystsDispersed particle separationMolecular sieveSynthesis methods

The invention relates to a preparation method of an integral molecular sieve SCR catalytic reactor, which is characterized in that the preparation method is as follows: adding molecular sieve original powder and metal oxide powder to the raw materials for making ceramic honeycomb carriers to form an outer surface Ceramic honeycomb catalyst carrier with molecular sieve powder. The molecular sieve powder in the carrier is used as a seed crystal, and the catalyst is grown on the honeycomb carrier by a direct synthesis method to make an integral SCR catalytic reactor. The raw materials are cheap, the sintering temperature is low, and the preparation method is simple. The molecular sieve and clay are blended and extruded. After being extracted, the molecular sieve is evenly distributed in all parts of the honeycomb body and serves as a seed crystal in the subsequent reaction of supporting the catalyst, which shortens the reaction time and increases the reaction yield; the metal salt solution used can be reused, reducing production costs. ; At the same time, the metal oxides in the pores of the honeycomb catalyst can serve as sulfur poisoning active centers to improve the durability of the honeycomb catalyst.

Owner:CHINA FIRST AUTOMOBILE

Transfer membrane specially used for environment-friendly rubber based on vulcanization process and vulcanizing transfer printing method

InactiveCN102285267BEliminates coating processAvoid playingDuplicating/marking methodsInksVulcanizationPolymer science

Owner:吕贵棠

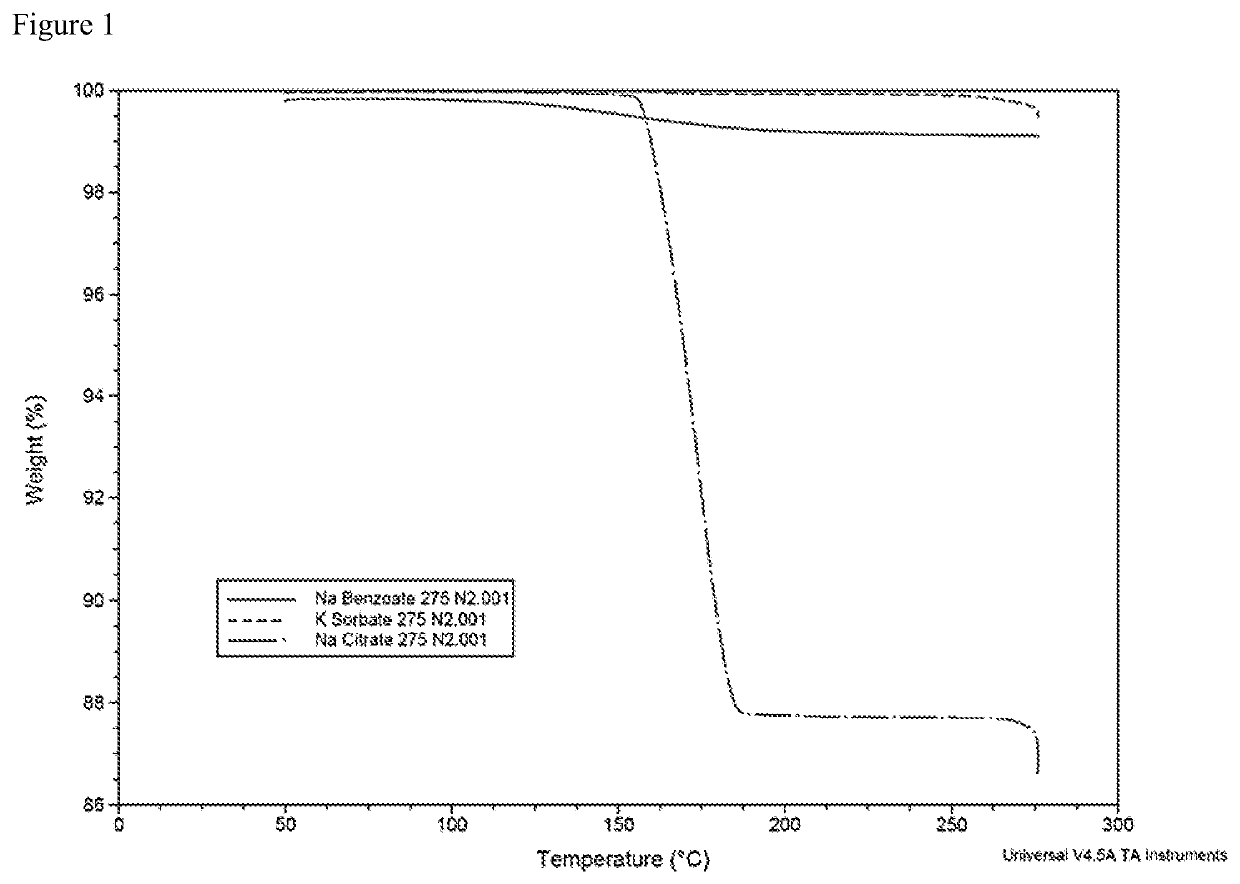

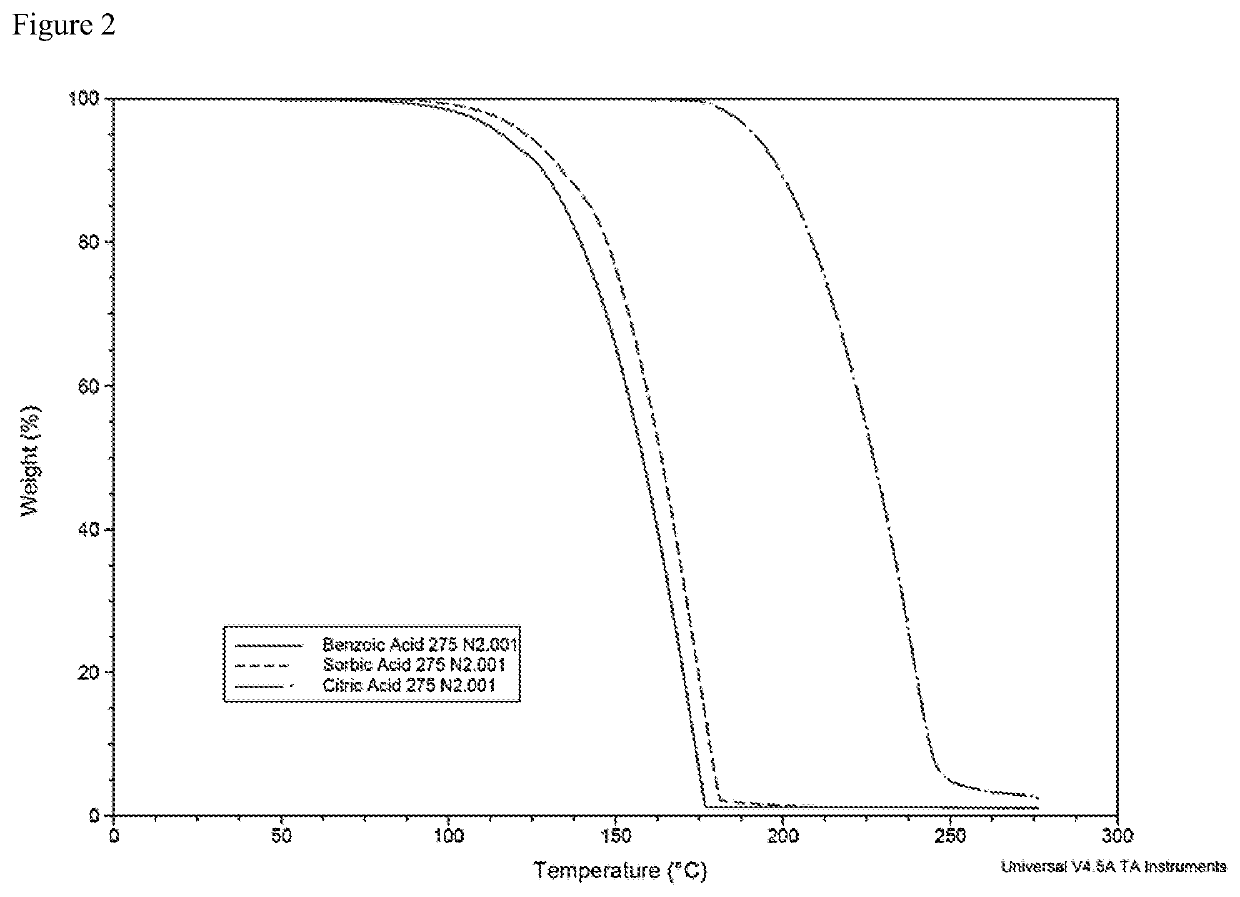

Composition and method for microbial control on material surfaces

PendingUS20210195892A1Increased durabilityElimination of coating process stepBiocideBiochemical fibre treatmentOrganic acidMicroorganism

A composition and method for microbial control on a material surface using a minimum risk pesticide such as a GRAS antimicrobial / preservative component. The GRAS antimicrobial / preservative component is preferably an organic acid.

Owner:MICROBAN PROD CO INC

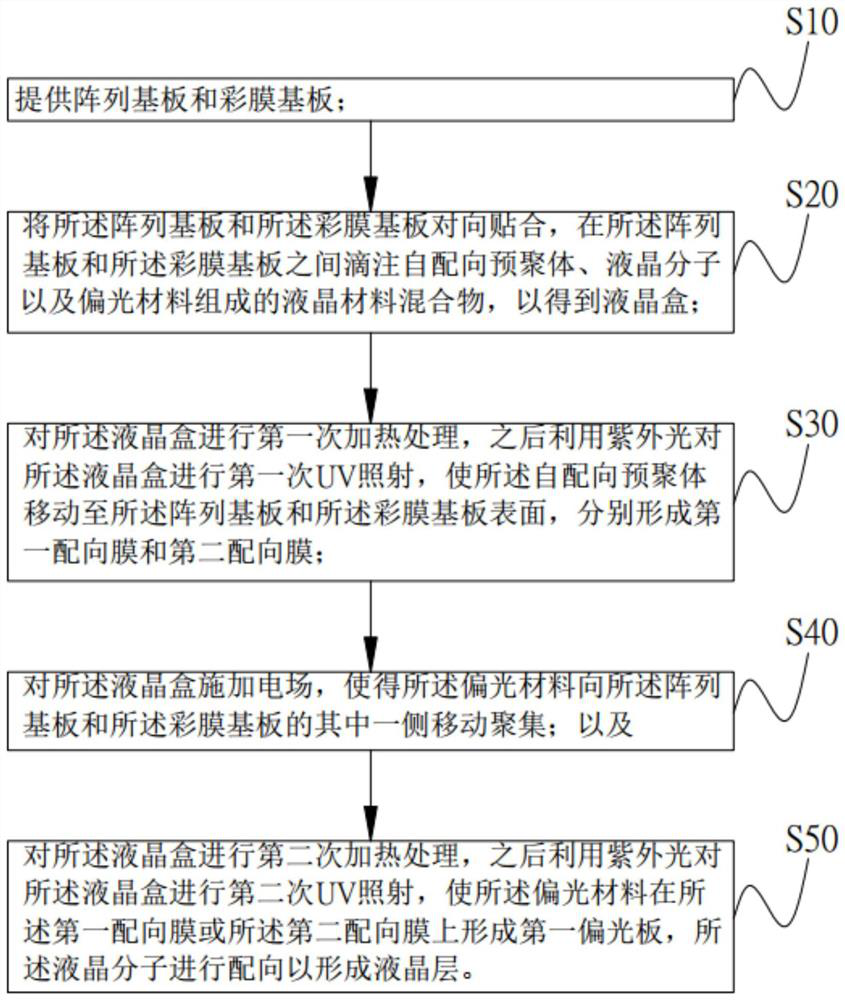

Manufacturing method of liquid crystal display panel, liquid crystal display panel

ActiveCN110703506BMeet the needs of one-shot moldingAvoid destructionNon-linear opticsCrystallographyQuantum dot

This disclosure provides a method for manufacturing a liquid crystal display panel and a liquid crystal display panel. The method for manufacturing a liquid crystal display panel includes injecting a mixture of a self-aligned liquid crystal material and a polarizing material into a liquid crystal cell, and after two times of UV irradiation, an alignment film is realized. And the requirement of one-time molding of the coating type polarizer saves the coating process of the alignment film and avoids the damage to the stability of the quantum dot material caused by the high temperature process.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A method for preparing silicon carbon negative electrode sheet by extrusion calendering and electrode sheet

ActiveCN112151768BHigh strengthGood compatibilityElectrode rolling/calenderingSecondary cellsFiberMetal foil

The present invention relates to the technical field of battery pole pieces, in particular to a method for preparing silicon-carbon negative electrode pieces by extrusion calendering, comprising: mixing PEDOT:PSS, chloroplatinic acid, and dimethyl sulfoxide to obtain modified PEDOT: PSS slurry; mix nano silicon powder, carbon fiber, sodium carboxymethyl cellulose, styrene-butadiene rubber emulsion with a mass concentration of 30%, and deionized water to obtain a silicon powder / carbon fiber composite slurry; PEDOT: PSS slurry Stir with silicon powder / carbon fiber composite slurry and extrude to obtain a paste; scrape and coat the paste to form a film. The invention solves the problem that the silicon-carbon negative electrode sheet is prone to peeling and cracking in the prior art. The above preparation method uses a flexible PEDOT:PSS film to replace the existing metal foil, and directly loads the negative electrode material on the pole piece, avoiding the problem of poor compatibility between the negative electrode active material and the pole piece in the traditional coating process. The procedure of the above preparation method is simple and controllable, and is suitable for large-scale and continuous production.

Owner:上海鲸孚科技有限公司

Film material for thermosetting resin molding and molded product thereof

PendingCN112238664AIncreased durabilityImprove mechanical propertiesSynthetic resin layered productsPaper/cardboard layered productsOrganic solventThin membrane

The invention provides a film material for thermosetting resin molding, wherein the film material at least comprises a first layer, a second layer and a third layer, an interface having a peel strength of 0.02-30 N / cm exists between the first layer and the second layer at the temperature of 23 DEG C, and the third layer is a porous body. The film material for thermosetting resin molding has the characteristics that the operation is easy, the removal is easy, the size precision of the surface of a mold is not damaged, the film material functional layer is transferred to the surface of thermosetting resin after the thermosetting resin is molded, the surface of a film joint is flat and free of concave and convex, and a molded product is endowed with functionality. The problems of volatilization of an organic solvent caused by use of a liquid release agent, high dust generation and polishing technical difficulty caused by subsequent molded body surface polishing, difficulty in ensuring design precision after repeated use of the mold and the like can be solved.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

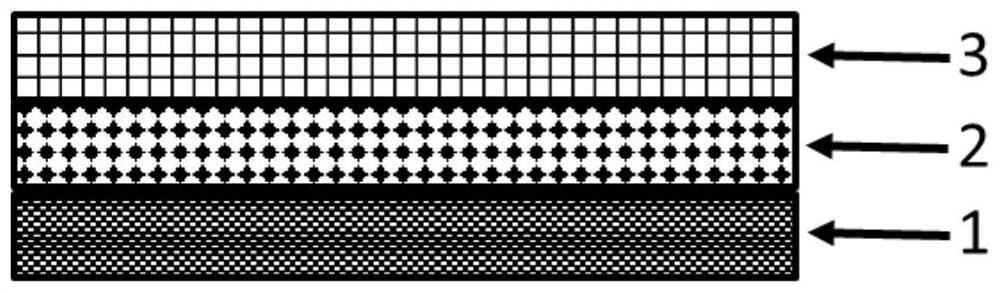

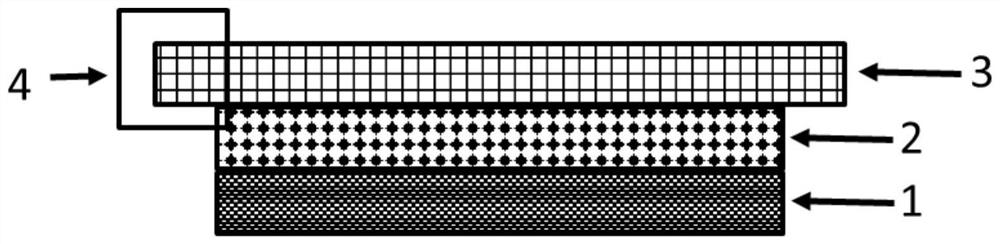

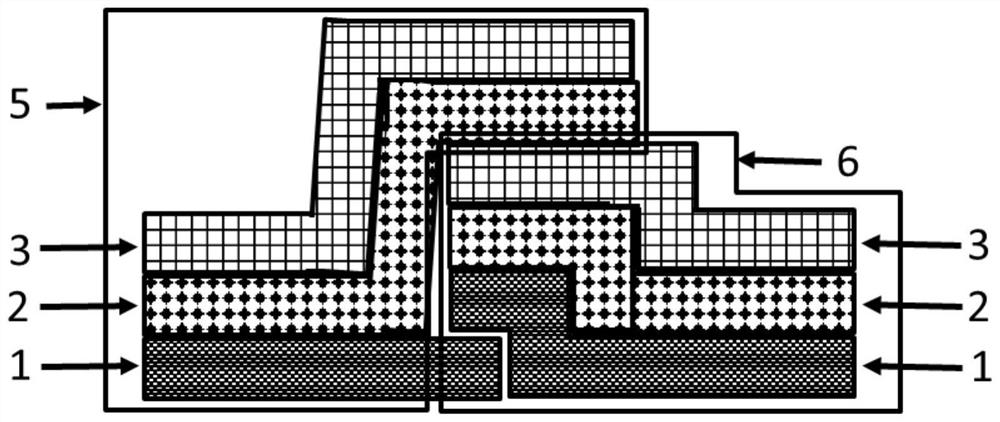

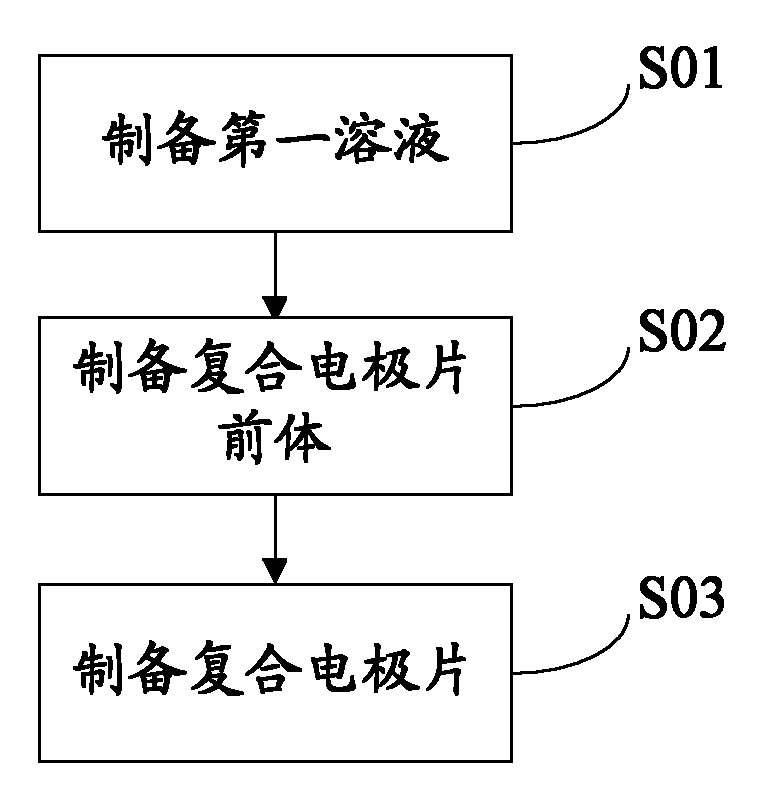

Preparation method and application of compound electrode slice

ActiveCN102956872BLower equivalent series resistanceLow costCell electrodesCapacitor electrodesComposite electrodeAlcohol

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of preparation technology of color inkjet printing photographic paper

ActiveCN107604754BGood ink absorptionHigh glossCoatings with pigmentsSpecial paperProcess engineeringPhotographic paper

The invention discloses a preparation process of a color ink-jet printing photographic paper. The process includes the steps of: (1) photographic paper surface treatment, (2) ink absorption layer preparation, and (3) gloss layer preparation. The invention perform reasonable optimization treatment on the existing printing photographic paper preparation technology, eliminates the prime paint coatingprocedure in the original technology, lowers the process complexity, and reduces adding of chemical paints. The preparation process provided by the invention is conducive to lowering the processing cost and reducing the paper thickness, and under the cooperation of the steps together, and the finally prepared printing photographic paper has enhanced ink absorption, glossiness, light resistance, folding resistance and the like, and good comprehensive usage quality, thus having substantial market competitiveness.

Owner:安徽文峰新材料科技股份有限公司

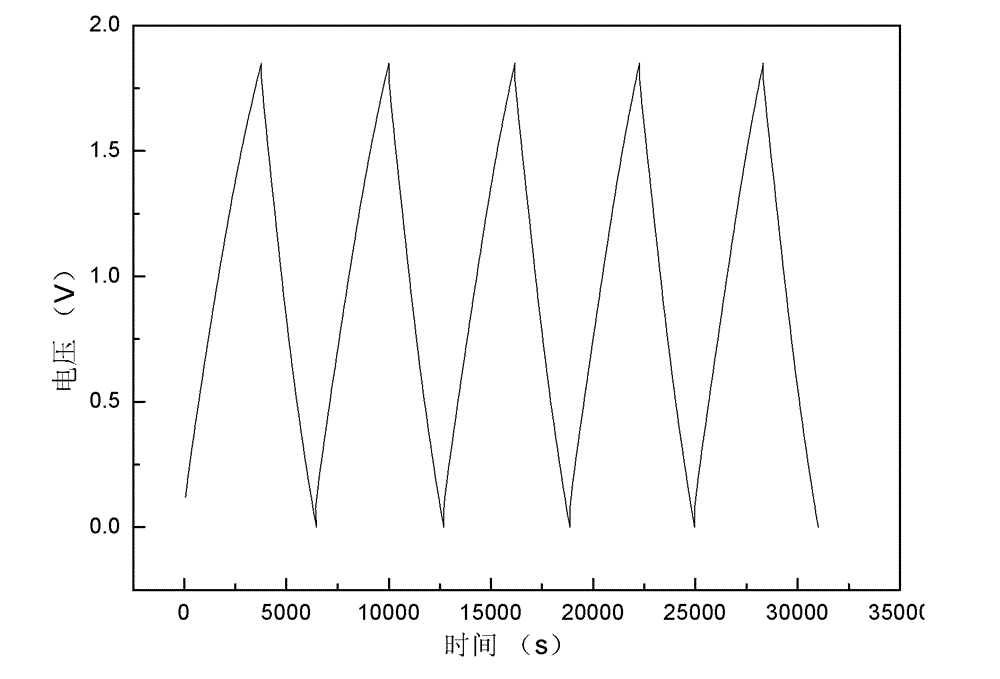

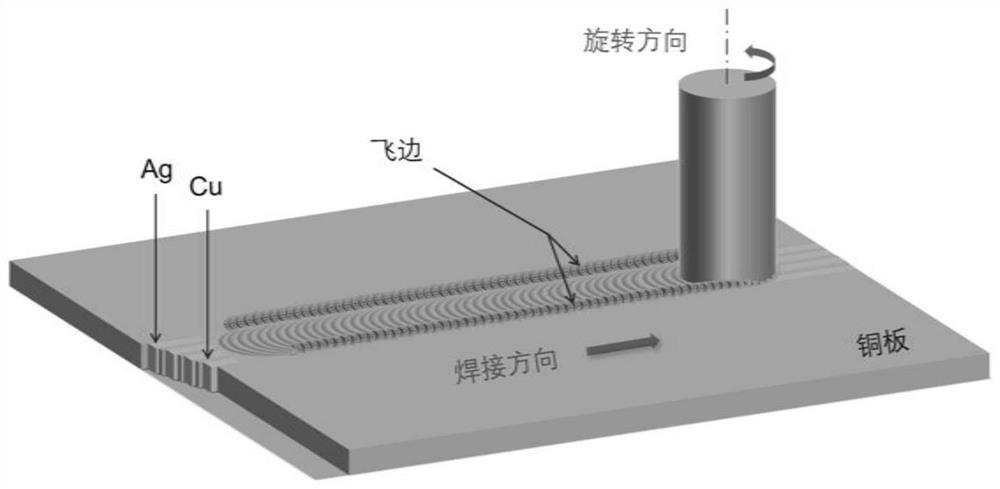

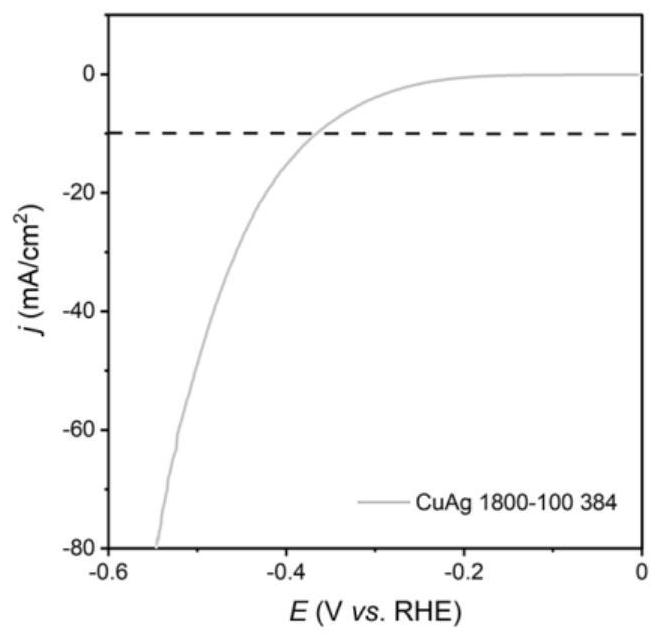

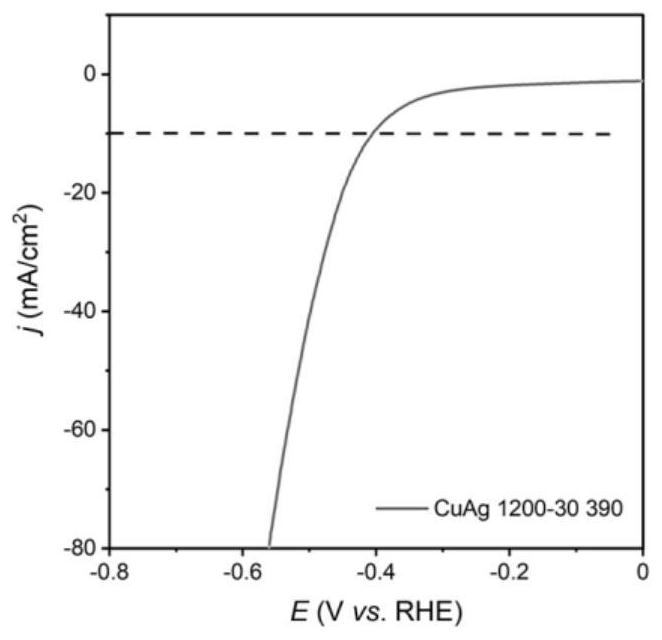

Method for preparing copper-silver alloy hydrogen evolution catalyst through friction stir processing

ActiveCN114289854AOvercoming problems not applicable to bulk materialsEliminates coating processNon-noble metal oxide coatingsNon-electric welding apparatusPtru catalystMetal alloy

The invention relates to a method for preparing a copper-silver alloy hydrogen evolution catalyst through friction stir processing. A blocky metal copper plate, a copper sheet and a silver sheet are used as raw materials; the metal copper plates and the copper-silver sheets arranged in a staggered mode are fixed to a workbench of a friction stir welding machine through a clamp, the silver sheets and the copper sheets are clamped between the two copper plates in a staggered mode, and the overlapping width of the copper-silver sheets is smaller than the diameter of a stirring head; a stirring head with a shaft shoulder is used; when machining begins, the stirring head is aligned with the copper-silver sheet, the stirring head is adjusted to be pressed downwards until the stirring needle is completely immersed into machining metal, and the stirring head automatically rotates and advances to the other end along one end of the copper-silver sheet for mixing once; the surface copper-silver boundary disappears; a metal strip extruded by a cut stirring head is directly used as a catalyst. The problem that an existing non-solid-solution metal alloying method is not suitable for block materials is solved. Friction stir processing is applied to the field of electro-catalysis for the first time, the process is simple and convenient to operate, toxic reaction raw materials are not used, and the method is an environment-friendly green synthesis process.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com