Preparation method of active nano porous nickel/nickel oxide load ultra-thin nickel cobaltate nanosheet flexible electrode material

A nanoporous nickel and flexible electrode technology, which is applied in the manufacture of hybrid/electric double layer capacitors, nanotechnology, nanotechnology, etc., can solve the problems of difficult control of the coating process, uneven distribution of active materials, and increased recycling costs. Rich usage scenarios, shortened experiment cycle, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides a method for preparing an active nanoporous nickel / nickel oxide loaded ultra-thin nickel cobaltate nanosheet composite electrode material, which mainly includes the following steps:

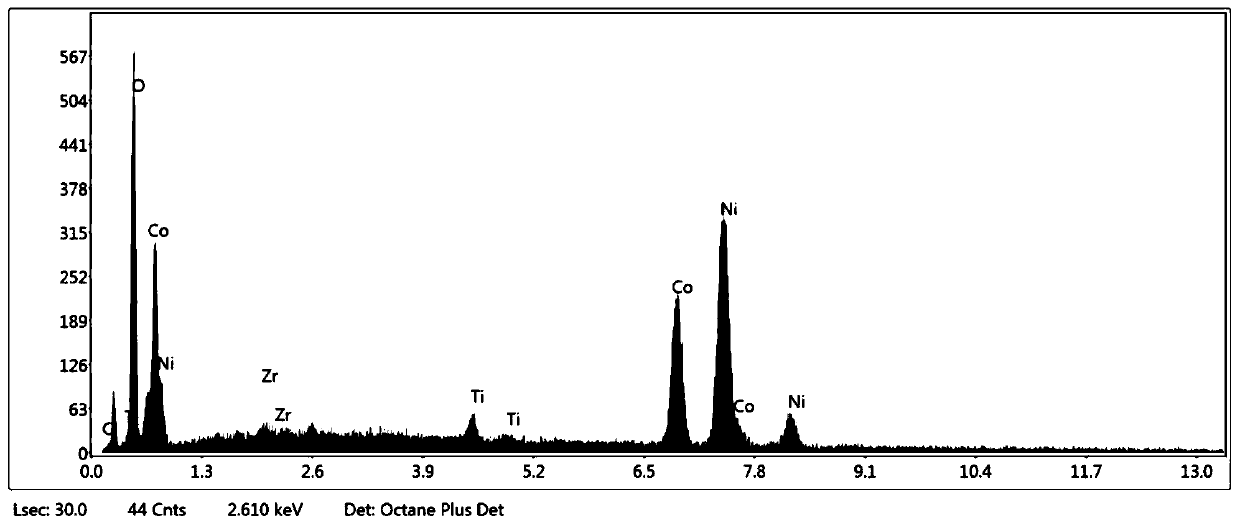

[0040] S1: Select the alloy composition as Ni 40 Zr 20 Ti 40 , the amorphous strip with a size of 2cm × 2mm × 20μm was used as a precursor, which was ultrasonically cleaned with absolute ethanol, and soaked in a mixed solution after cleaning (40ml 0.05M HF solution and 10ml 5% H 2 o 2 After the solution is mixed, obtain) free dealloying for 4h to obtain a nanoscale porous nickel / nickel oxide template;

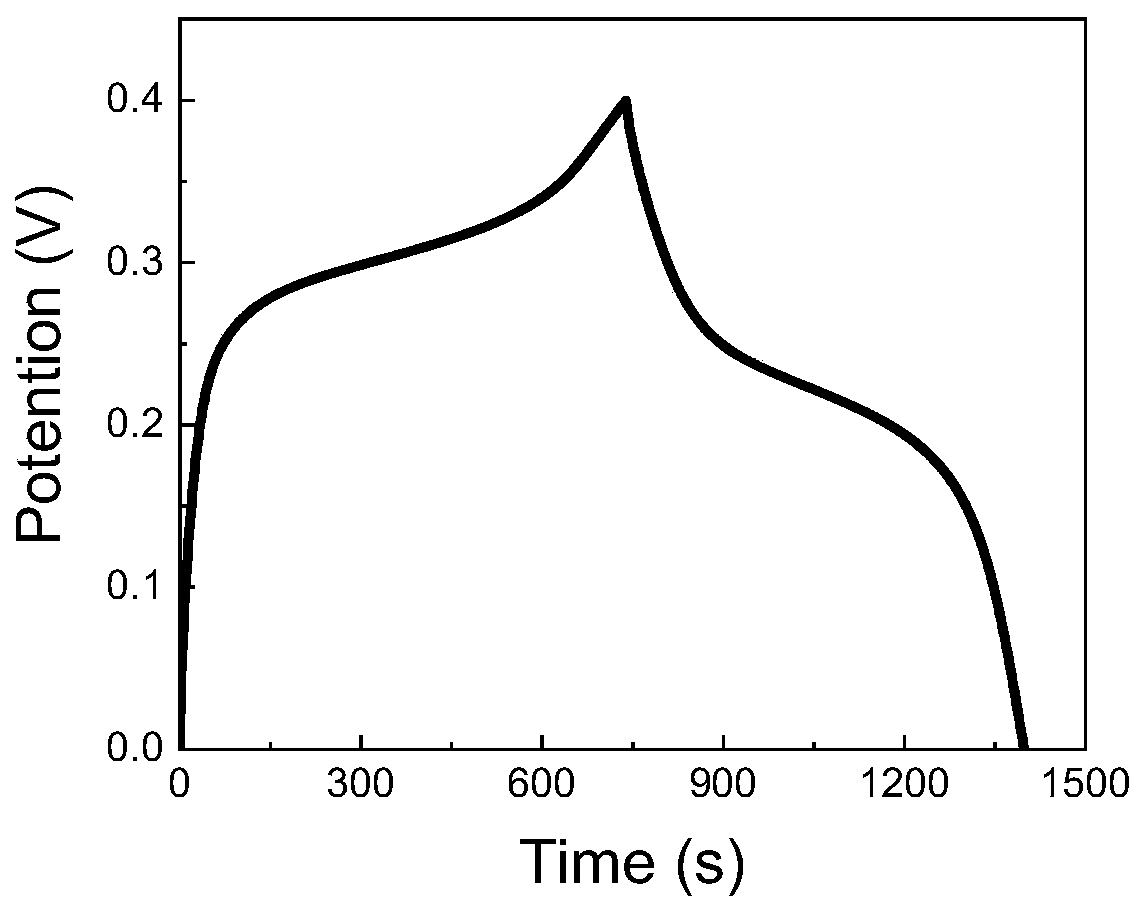

[0041] S2: Under the three-electrode system, the template prepared in S1 was used as the working electrode, the metal Pt sheet was used as the counter electrode, and the Ag / AgCl electrode was used as the reference electrode, and the solution mixed with cobalt nitrate hexahydrate and urea at a concentration ratio of 10:1 was used as The electrolyte, wherein the mol...

Embodiment 2

[0048] S1: Select Ni with a size of 1cm×1.5mm×25μm 40 Zr 20 Ti 40 The amorphous strip is the precursor, and it is ultrasonically cleaned with absolute ethanol. After cleaning, it is soaked in 40ml of 0.05M HF solution and 10ml of 5% H 2 o 2 Free dealloying in the mixed solution for 4 hours to obtain a nanoscale porous nickel / nickel oxide template;

[0049] S2: Under the three-electrode system, the template made in S1 is used as the working electrode, the metal Pt sheet is used as the counter electrode, the Ag / AgCl electrode is used as the reference electrode, and the solution mixed with cobalt nitrate hexahydrate and urea at a ratio of 8:1 is used as the electrolysis solution, wherein the molar concentration of cobalt nitrate hexahydrate is 6mM, and cobalt hydroxide nanosheets are deposited on the surface of nanoporous nickel. The deposition potential is -1.2V, and the time is 30min;

[0050] S3: Rinse the material prepared in S2 with deionized water for 3 to 4 times, pla...

Embodiment 3

[0054] S1: Select Ni with a size of 5cm×3mm×30μm 40 Zr 20 Ti 40 The amorphous strip is the precursor, and it is ultrasonically cleaned with absolute ethanol. After cleaning, it is soaked in 40ml of 0.05M HF solution and 10ml of 5% H 2 o 2 Free dealloying in the mixed solution for 4 hours to obtain a nanoscale porous nickel / nickel oxide template;

[0055] S2: Under the three-electrode system, the template made in S2 is used as the working electrode, the metal Pt sheet is used as the counter electrode, and the Ag / AgCl electrode is used as the reference electrode, and the ratio of cobalt nitrate hexahydrate, nickel nitrate hexahydrate, and urea is 5:1. The mixed solution is an electrolyte, wherein the molar concentration of cobalt nitrate hexahydrate is 3mM, and cobalt hydroxide nanosheets are deposited on the nanoporous nickel surface. The deposition potential is -1.5V, and the time is 60min;

[0056] S3: Rinse the material prepared in S2 with deionized water for 3 to 4 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com