Graphene composite electrode and preparation method and application

A graphene composite and graphene technology, which is applied to battery electrodes, circuits, capacitors, etc., can solve the problems of narrow working potential window, difficult industrial use, and high price, so as to save the coating process, shorten the time, and improve the Effects of Stability and Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

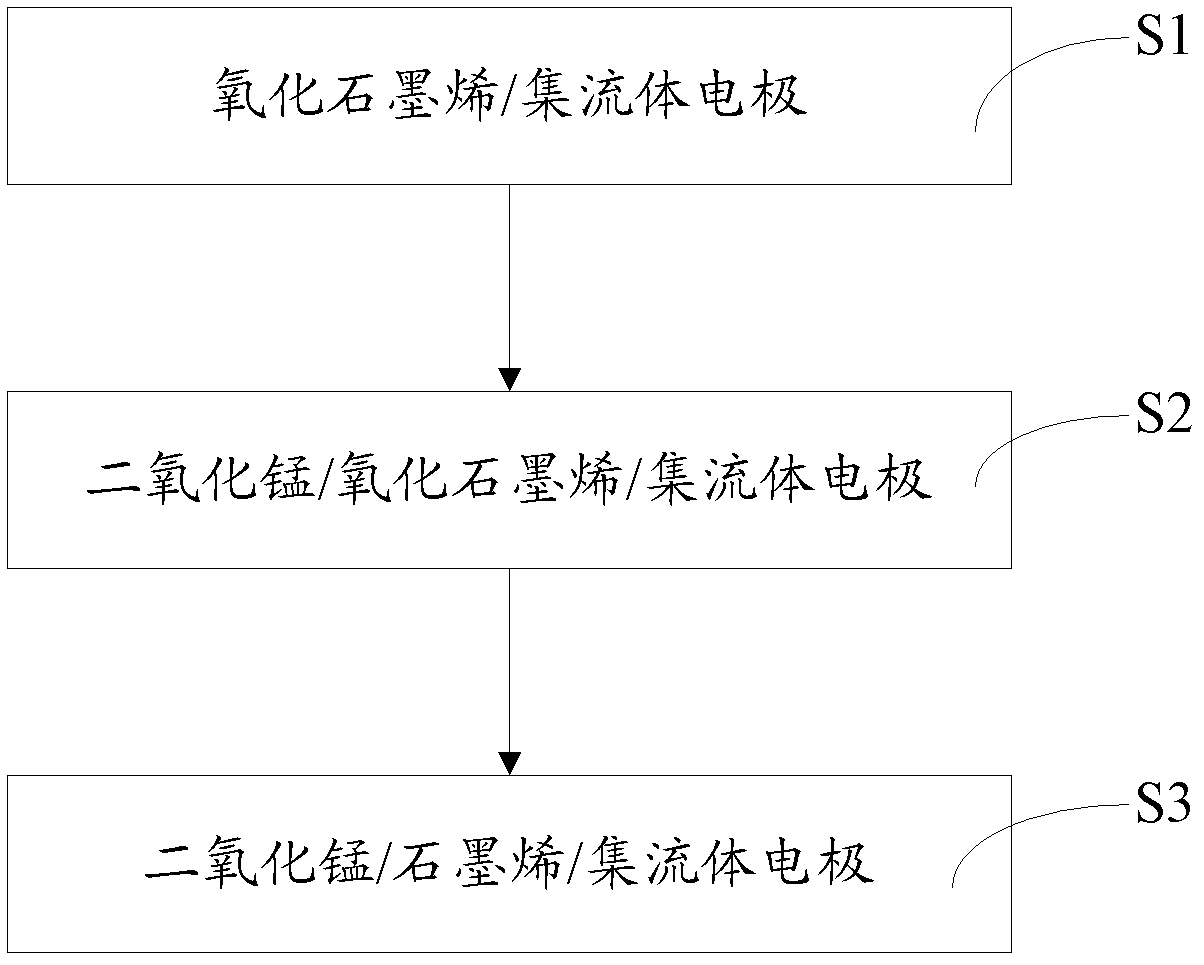

[0026] Such as figure 1 As shown, the preparation method of the graphene composite electrode of the present embodiment comprises the following steps:

[0027] Step S1: ultrasonically disperse graphite oxide in a solvent to prepare a graphene oxide solution, and then deposit graphene oxide on the surface of the current collector by electrodeposition to obtain a graphene oxide / current collector electrode.

[0028] Preferably, the graphite oxide in this step is prepared according to the following steps: add graphite powder to concentrated sulfuric acid at 0°C, then add potassium permanganate, keep the temperature of the system below 10°C, stir for 2 hours, and then cool it at room temperature Stir in a water bath for 24 hours, then slowly add deionized water to the reaction system under ice bath conditions, and then add deionized water containing hydrogen peroxide after 15 minutes until the color of the solution turns bright yellow, suction filter while it is hot, and then use W...

Embodiment 1

[0037] The process flow is as follows:

[0038] Natural flake graphite→graphite oxide→graphene oxide / nickel electrode→manganese dioxide / graphene oxide / nickel electrode→manganese dioxide / graphene / nickel electrode

[0039] (1) Natural flake graphite: 100 mesh.

[0040] (2) Graphite oxide: Add 0.5g of 100 mesh natural flake graphite powder to 0°C, 11.5mL of concentrated sulfuric acid, then add 1.5g of potassium permanganate, keep the temperature of the mixture below 10°C, stir for 2 hours, Then, after stirring in a water bath at room temperature for 24 hours, 46 mL of deionized water was slowly added in an ice bath. After 15 minutes, add 140mL of deionized water (which contains 2.5mL of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow. Suction filtration, then 250mL of 10% hydrochloric acid is used for washing, suction filtration, 60 ℃ vacuum drying for 48 hours to obtain graphite oxide.

[0041] (3) Graphene oxide / nickel electrode: Add the grap...

Embodiment 2

[0046] The process flow is as follows:

[0047] Natural flake graphite→graphite oxide→graphene oxide / aluminum electrode→manganese dioxide / graphene oxide / aluminum electrode→manganese dioxide / graphene / aluminum electrode

[0048] (1) Natural flake graphite: 500 mesh.

[0049] (2) Graphite oxide: Add 0.5g of 500 mesh natural flake graphite powder into 0°C, 11.5mL of concentrated sulfuric acid, then add 1.5g of potassium permanganate, keep the temperature of the mixture below 10°C, stir for 2 hours, then After stirring in a water bath at room temperature for 24 hours, 46 mL of deionized water was slowly added in an ice bath. After 15 minutes, add 140mL of deionized water (which contains 2.5mL of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow. Suction filtration, then 250mL of 10% hydrochloric acid is used for washing, suction filtration, 60 ℃ vacuum drying for 48 hours to obtain graphite oxide.

[0050] (3) Graphene oxide / aluminum electrode: Gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com