Film material for thermosetting resin molding and molded product thereof

A technology of resin molding and film materials, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the adverse effects on the health of workers, defects at the seams of molded products, and affect the mechanical properties of molded products To achieve the effect of improving material durability and mechanical properties, reducing surface grinding and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

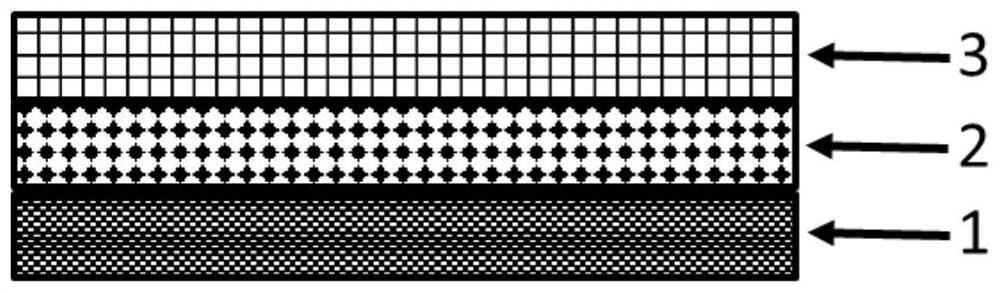

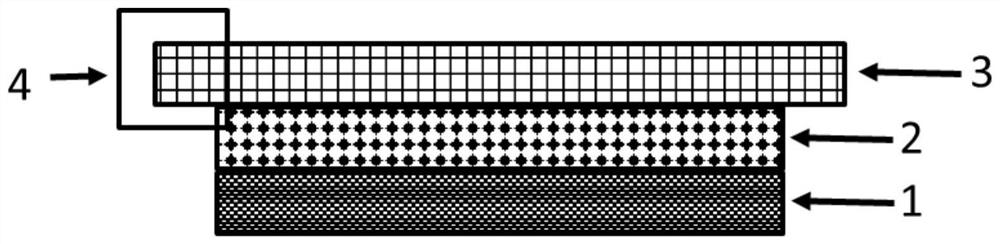

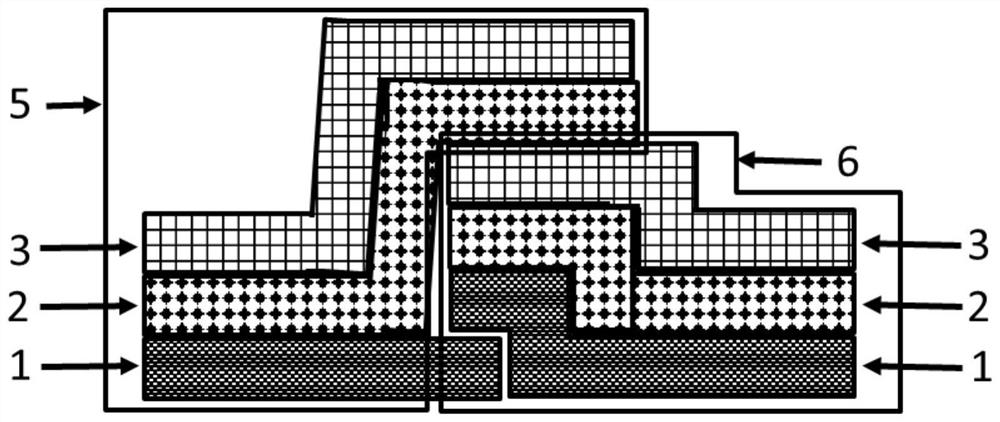

[0093] According to the composition shown in Table 1, use the 170222 series wet film preparation device produced by Shanghai Modern Environmental Engineering to apply the stock solution of the second layer on one side of the first layer, and then cure it under the curing conditions of the second layer used. To obtain the second layer with a thickness of 100 μm, use the MRK-65 model laminating machine produced by MCK Company, set the laminating roller speed of the laminating machine to 15rpm, and coat the third layer on the surface of the second layer, and the edge of the third layer flush with the second layer. Wherein, in embodiment 1-3, the second layer is arranged on the non-release surface of A1; in embodiment 4-6, the second layer is arranged on the release surface of A1; in embodiment 7-9, the second The layer was placed on the self-adhesive surface of A2; in Examples 10-12, the second layer was placed on either side of A3.

[0094] Various performance tests were carrie...

Embodiment 13-19

[0096] According to the composition shown in Table 2, use the 170222 series wet film preparation device produced by Shanghai Modern Environmental Engineering Co., Ltd. to apply the stock solution of the second layer on the release surface of A1, and then cure it under the curing conditions of the second layer used to obtain For the second layer with a thickness of 100 μm, use the MRK-65 model laminating machine produced by MCK Company, set the laminating roller speed of the laminating machine to 15rpm, and coat the third layer of different materials on the surface of the second layer. The edge of the layer is flush with the second layer.

[0097] Various performance tests were carried out on the obtained samples, and the results are listed in Table 2.

Embodiment 20-21

[0099] According to the composition shown in Table 3, use the 170222 series wet film preparation device produced by Shanghai Modern Environmental Engineering to apply the stock solution of the adhesive layer on the non-self-adhesive surface of A2, and then cure it under the curing conditions of the adhesive layer used to obtain Adhesive layer with a thickness of 5 μm.

[0100] Then, according to the composition shown in Table 3, use the 170222 series wet film preparation device produced by Shanghai Modern Environmental Engineering to coat the stock solution of the second layer on the other side of the first layer, and then use the curing conditions of the second layer Curing at the bottom to obtain a second layer with a thickness of 100 μm. Use the MRK-65 model laminating machine produced by MCK Company, set the laminating roller speed of the laminating machine to 15rpm, and coat the third layer on the surface of the second layer. The edge of the third layer is flush with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com