Composition and method for microbial control on material surfaces

a technology of microbial control and material surface, applied in the field of composition and method for microbial control on a material surface, can solve the problems of affecting the aesthetics of treated articles, affecting the temperature of chemicals, and being sensitive to ultraviolet degradation, so as to eliminate the coating process step and increase the durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

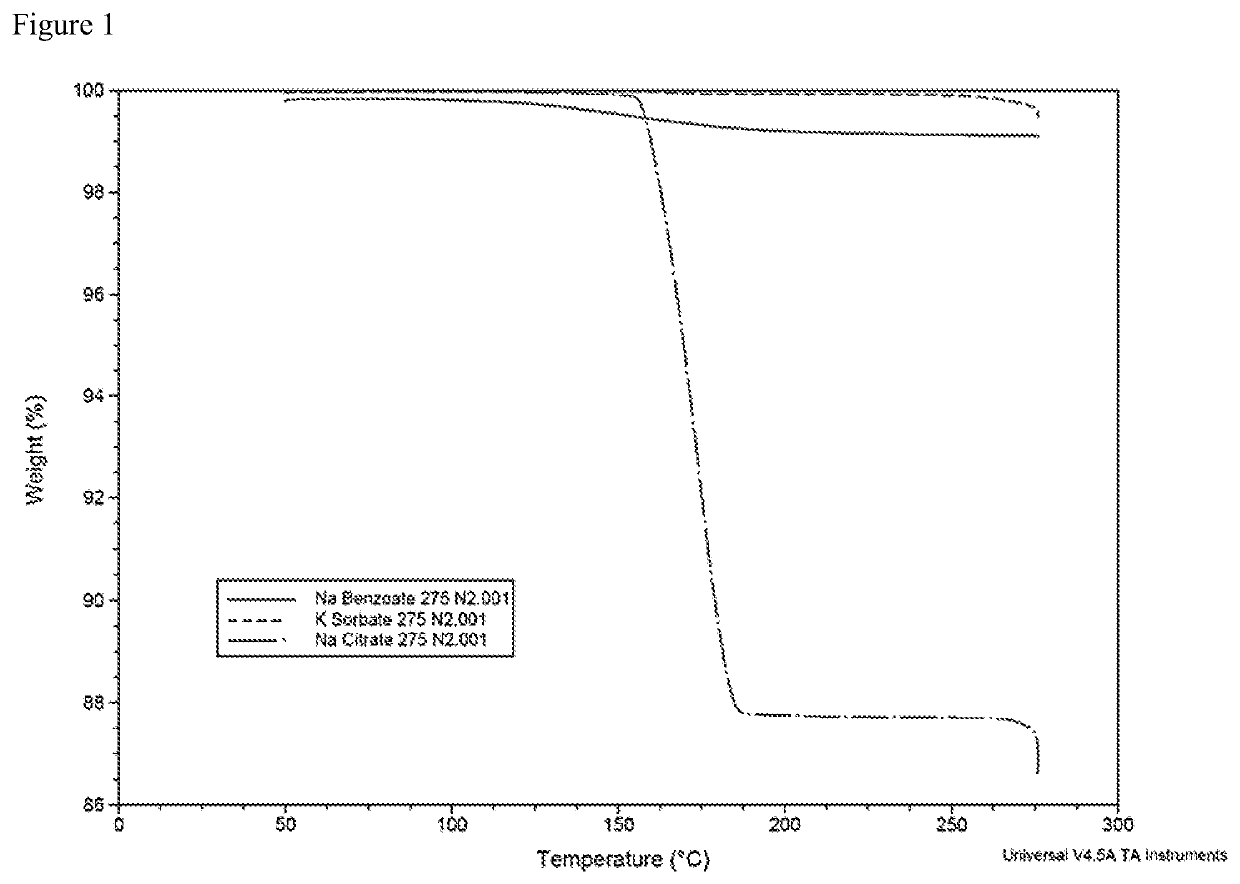

[0033]Initial work focused on three GRAS chemistries, the salts of benzoic acid, sorbic acid, and citric acid. FIG. 1 shows a TGA plot of these salts that indicates all salts are thermally stable to temperatures greater than 300° C.

[0034]In FIG. 1, the TGA Plot at 10° C. / min showed volatization of GRAS salts up to 275° C. The sorbate and citrate salts were stable (did not lose any mass) to temperatures greater than 275° C., while the citrate was approximately 10% water which is why it lost approximately 10% weight then leveled out—the salt itself did not volatize. This thermal stability and reported antimicrobial efficacy made these compounds seemingly ideal for this application.

[0035]Each salt chemistry was evaluated by compounding into a polyolefin carrier at 10% concentrate level, then using that polymer concentrate as a masterbatch to injection mold PP plaques at various end-use levels for testing. Commodity PP and EMA materials in a twin-screw extruder for compounding, and in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com