Fluoro graphene oxide electrode and preparation method thereof

A fluorinated oxygen and fossil technology, applied in the field of electrochemical energy, can solve the problems of lower specific surface area, lower performance of supercapacitors and lithium-ion batteries, lower specific capacity, etc., achieve simple process technology, save coating process and parameters controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

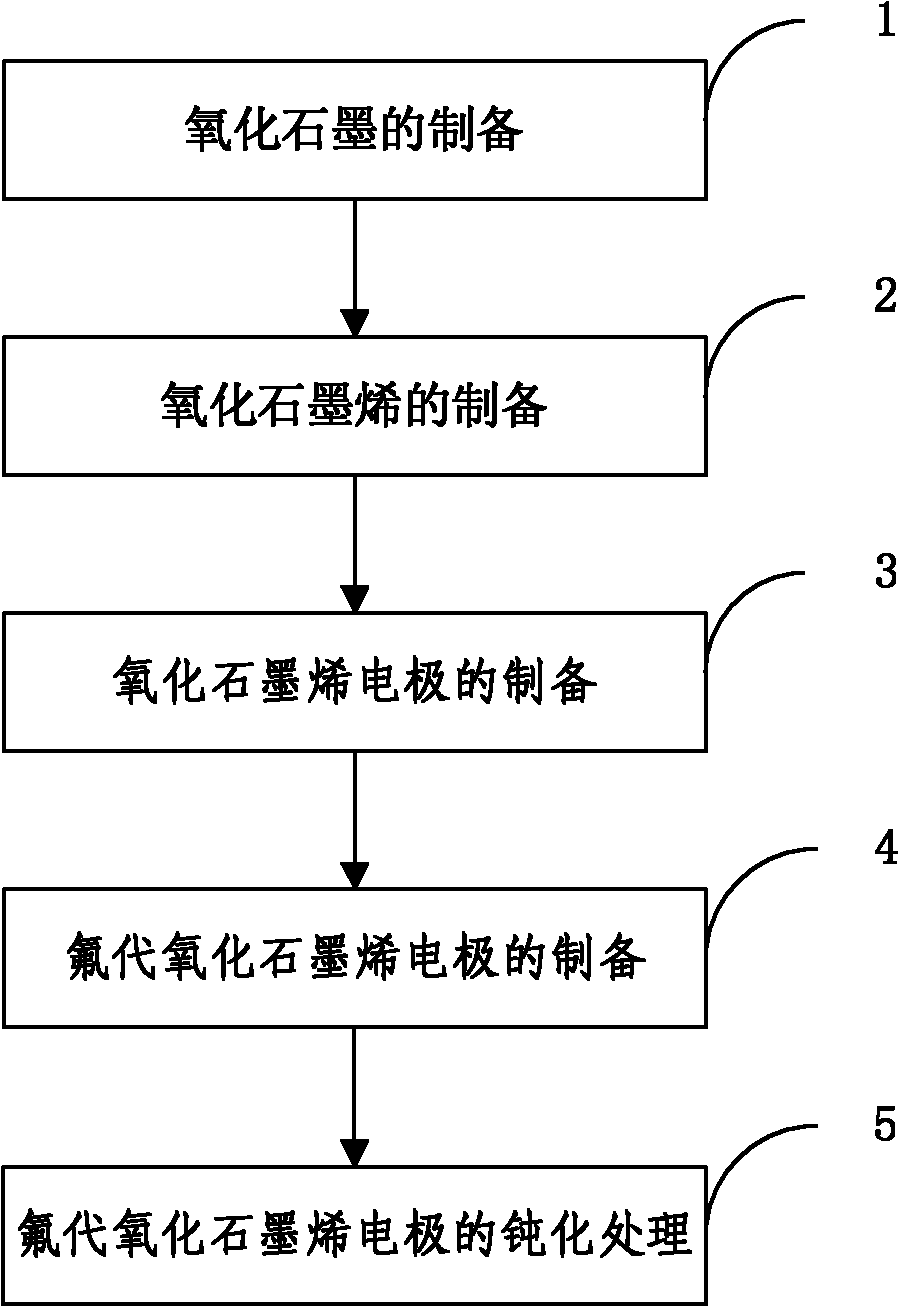

[0020] The preparation process of the above-mentioned fluorinated graphene oxide electrode is as follows:

[0021] Graphite → graphite oxide → graphene oxide → graphene oxide electrode → fluorinated graphene oxide electrode → passivated fluorinated graphene oxide electrode.

[0022] like figure 1 As shown, the preparation process steps of the fluorinated graphene oxide electrode are as follows:

[0023] Step 1, preparation of graphite oxide: utilize graphite flakes, such as natural flake graphite with a purity of 99.5%, to prepare graphite oxide by the Hummers method (extracted from JACS, 1958, 80, 1339);

[0024] Step 2, preparation of graphene oxide: adding the prepared graphite oxide into water for ultrasonic dispersion to form a graphene oxide solution uniformly dispersed in a single layer, filtering and drying to obtain graphene oxide;

[0025] Step 3, preparation of graphene oxide electrode: Add graphene oxide to a container filled with water or NMP (N-methylpyrrolidon...

Embodiment 1

[0040] The preparation technological process of fluorinated graphene oxide electrode among the present invention is as follows:

[0041] Graphite → Graphene Oxide → Graphene Oxide Electrode → Fluorinated Graphene Oxide Electrode

[0042] (1) Graphite: purity 99.5%;

[0043] (2) Graphene oxide: Utilize graphite with a purity of 99.5%, to obtain graphene oxide through the improved Hummers method (extracted from JACS, 1958, 80, 1339);

[0044] (3) Ultrasonic disperse the prepared graphene oxide into water, place a current collector aluminum foil at the bottom of the container, stand still and deposit for 12 hours, take out the pole piece, dry, and obtain a graphene oxide electrode;

[0045] (4) fluorinated graphene oxide electrode: the graphene oxide electrode obtained in (3) is passed through with F2 React to obtain a fluorinated graphene oxide electrode; put the dried graphene oxide electrode into the reactor and pass through dry nitrogen for 0.5h, then pass through fluorine g...

Embodiment 2

[0048] The preparation technological process of fluorinated graphene oxide electrode among the present invention is as follows:

[0049] Graphite → Graphene Oxide → Graphene Oxide Electrode → Fluorinated Graphene Oxide Electrode

[0050] (1) Graphite: purity 99.5%;

[0051] (2) Graphene oxide: with embodiment 1;

[0052] (3) Graphene oxide electrode: ultrasonically disperse the prepared graphene oxide into water, place a current collector aluminum foil at the bottom of the container, stand still and deposit for 48 hours, take out the pole piece, and dry;

[0053] (4) Fluorinated graphene oxide electrode: put the dried graphene oxide electrode into the reactor and pass through dry nitrogen gas for 0.5h, then pass through fluorine gas and react with graphene oxide at 20°C for 24h, then you can Obtain fluorinated graphene oxide; continue to feed the mixed gas of fluorine and nitrogen into the reactor, and in the whole reactor, fluorine accounts for 5% (volume ratio) of the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com