A vulcanized polyacrylonitrile film with hollow tubular nanofibers and a binder-free lithium sulfide battery positive electrode prepared from the film

A technology of vulcanized polyacrylonitrile and nanofiber, which is applied in battery electrodes, lithium batteries, nanotechnology, etc., can solve the problems of reducing battery energy density, making no contribution to battery capacity, and increasing battery cost, so as to improve utilization rate and save The effect of coating process and long-lasting cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

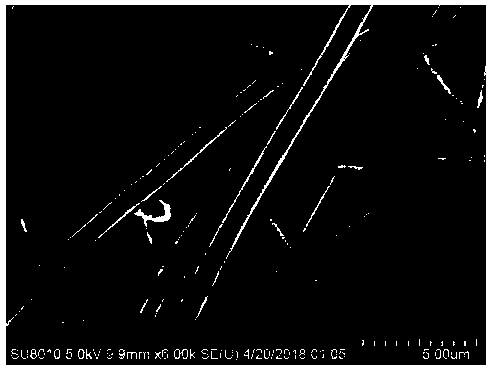

Image

Examples

Embodiment 1

[0037] 1. A vulcanized polyacrylonitrile film with hollow tubular nanofibers, the specific preparation process is as follows:

[0038] (1) According to the mass ratio of 1:9, prepare a polyacrylonitrile solution with a mass fraction of 10% from polyacrylonitrile and dimethylformamide, and perform magnetic stirring for 12 hours; similarly prepare a polyacrylonitrile solution with a mass fraction of 10%. Polyethylene oxide solution, the solvent is dimethylformamide, stirred at 60°C for 3h; then, the two solutions were sonicated for 30min;

[0039](2) Composite nanofibers were prepared by coaxial electrospinning technology, in which the polyethylene oxide solution was the core layer spinning solution, the polyacrylonitrile solution was the shell layer spinning solution, and the spinning solution flow rate of the inner and outer shafts was 20uL / min , the spinning voltage is 15KV, the receiving distance of the roller is 15cm, and the rotating speed of the roller is 500r / min, the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com