Graphene electrode plate and preparing method thereof

A graphene electrode and graphene technology, applied in the field of electrochemical materials, can solve the problems of increased contact internal resistance, low power density, high equivalent series resistance of electrode sheets, etc., to reduce contact internal resistance, increase power density, reduce etc. The effect of effective series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method of a graphene electrode sheet provided by the present invention is composed of a graphene film and a current collector. By dispersing graphene in an ionic liquid, a stable graphene suspension is obtained, and then the graphene suspension is electrodeposited The method is deposited on the current collector to obtain a graphene electrode sheet.

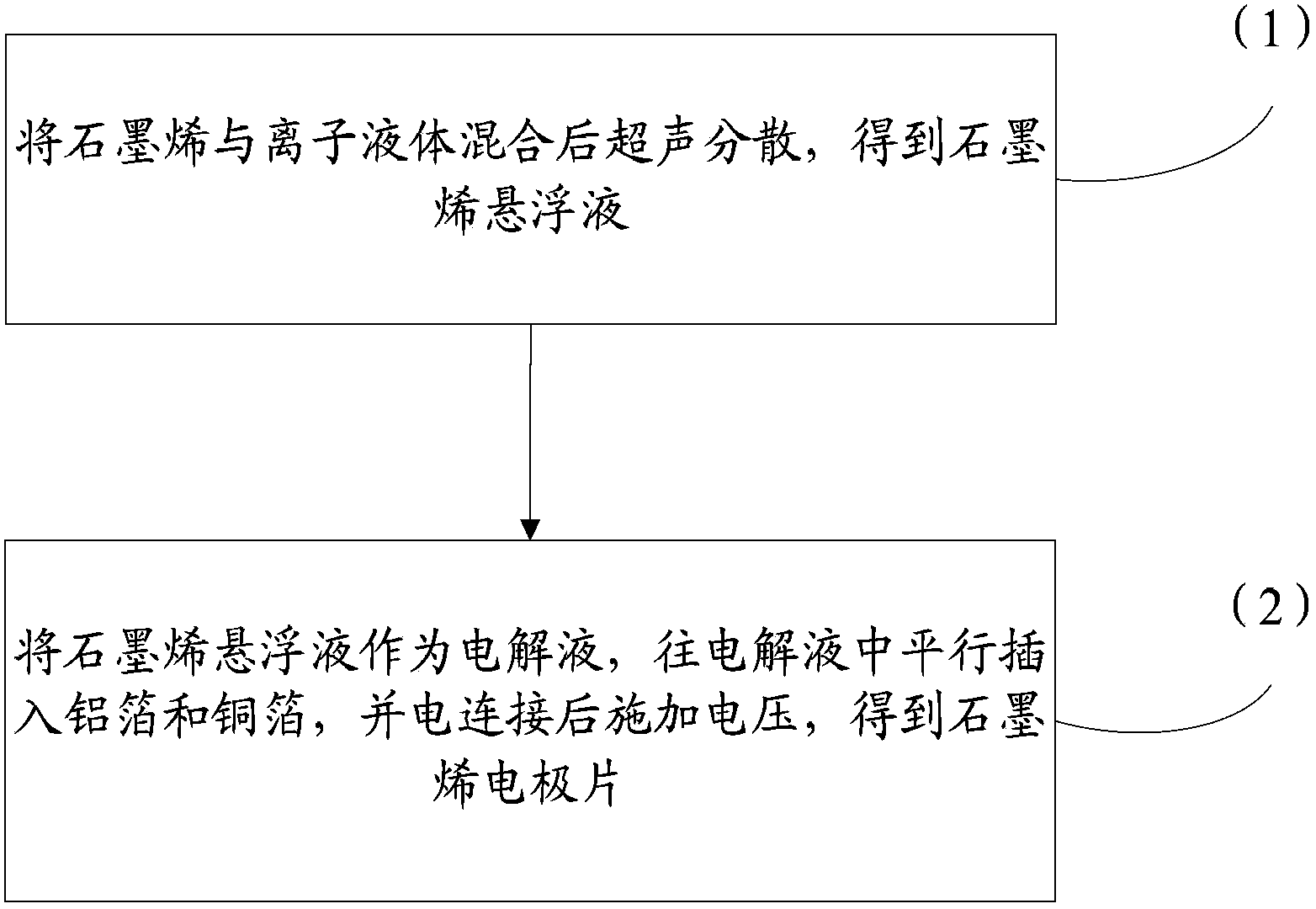

[0018] Such as figure 1 Shown, the preparation technological process of a kind of graphene electrode sheet is as follows:

[0019] (1) Preparation of graphene suspension:

[0020] After mixing the graphene and the ionic liquid, grind it with an agate mortar for 5-20 minutes, and then add the mixture into the solvent for ultrasonic dispersion for 1-5 hours to form a graphene suspension with a concentration of 0.1-5 mg / ml;

[0021] Wherein, the solvent can be water, DMF, DMSO, DMAc or NMP; the ionic liquid can be an imidazole ionic liquid, or a pyrrolidine ionic liquid; the imidazole ionic liquid includes: 1-...

Embodiment 1

[0027] The preparation process of the graphene electrode sheet synthesized by the present invention is as follows:

[0028] (1) Preparation of graphene suspension: Mix 1g of graphene and 1g of 1-ethyl-3-methylimidazolium tetrafluoroborate with an agate mortar for 5min, then add the mixture into DMF solvent for ultrasonic dispersion After 5 hours, a graphene suspension with a concentration of 0.1 mg / ml was formed.

[0029] (2) Preparation of graphene electrode sheet: use the graphene suspension in (1) as the electrolyte, take two copper foils with a diameter of 5 cm as the anode electrode and the cathode electrode respectively, and place the two electrodes in parallel and symmetrically into the electrolyte , the distance between the two electrodes is 0.5cm, a 40V direct current is added to both ends of the electrodes, electrophoresis is carried out for 5min, the copper foil as the cathode is removed, and dried in a vacuum oven at 100°C to obtain a graphene electrode sheet.

Embodiment 2

[0031] (1) Preparation of graphene suspension: Mix 1g of graphene and 3g of 1-butyl-3-methylimidazolium hexafluorophosphate, grind with an agate mortar for 20min, then add the mixture into DMSO solvent for ultrasonic dispersion for 5h , forming a graphene suspension with a concentration of 2 mg / ml.

[0032] (2) Preparation of graphene electrode sheets: use the graphene suspension in (1) as the electrolyte, take two aluminum foils with a diameter of 10 cm as the anode electrode and the cathode electrode respectively, and place the two electrodes in parallel and symmetrically into the electrolyte , the distance between the two electrodes is 0.5cm, add 80V direct current at both ends of the electrodes, electrophoresis for 20min, remove the aluminum foil as the cathode, and dry it in a vacuum oven at 100°C to obtain a graphene electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com