A preparation method of thin-film electrodes based on covalent organic framework materials

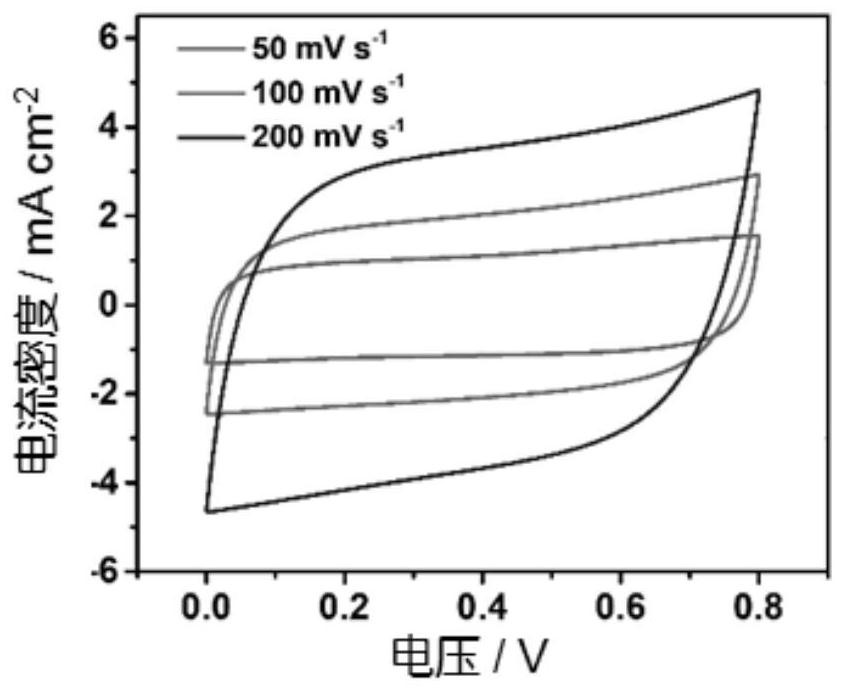

A covalent organic framework and thin-film electrode technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems affecting capacitance performance, decrease in the number of electrochemical active sites, poor conductivity, etc., and achieve excellent capacitance Performance, Elimination of preprocessing steps, Effects of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 42.8 mg of 1,3,5-trimethyl-2,4-dicyanopyridine, 98.4 mg of 2,4,6-tris(p-formylphenyl)-1,3,5-tris to a 15 mL pressure bottle Oxyzine, 130mg of anhydrous piperidine and 10mL of anhydrous N,N-dimethylformamide were heated to 120°C for 48h under the protection of argon. After the reaction, the solid was collected by vacuum filtration, washed with dichloromethane and water, and the collected solid was dried in vacuum for 24 hours to obtain a yellow solid product, a nitrogen-rich covalent organic framework material with fully conjugated carbon-carbon double bonds, about 100 mg.

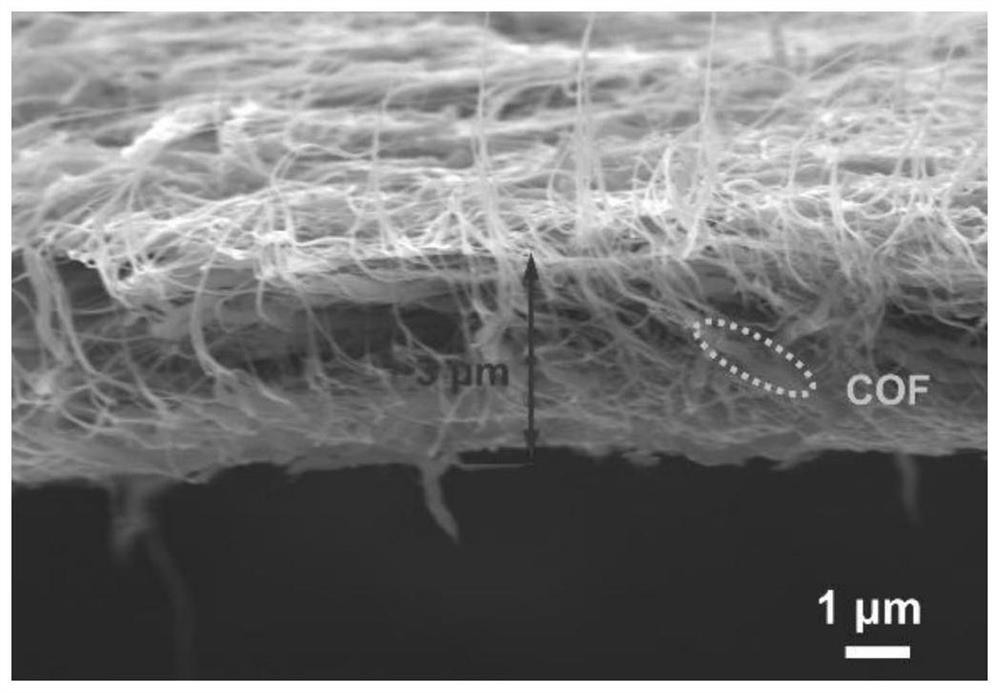

[0035] 14 mg of the prepared covalent organic framework material and 6 mg of commercially available single-walled carbon nanotubes were dispersed with 20 mL of N,N-dimethylformamide, and the dispersion liquid was homogenized using probe ultrasound to obtain a dispersion liquid.

[0036] An organic film with a pore size of 0.22 microns is used as a filter membrane, and the filter membrane is cover...

Embodiment 2

[0039] Add 30 mg of 1,3,5-trimethyl-2,4-dicyanopyridine, 90 mg of 2,4,6-tris(p-formylphenyl)-1,3,5-triazine, 120mg of anhydrous piperidine and 5mL of anhydrous N,N-dimethylformamide were heated to 110°C for 60h under the protection of argon. After the reaction, the solid was collected by vacuum filtration, washed with dichloromethane and water, and the collected solid was vacuum-dried for 20 h to obtain a yellow solid product, a nitrogen-rich covalent organic framework material linked by fully conjugated carbon-carbon double bonds.

[0040] 10 mg of the prepared covalent organic framework material and 1 mg of commercial single-walled carbon nanotubes were dispersed with 10 mL of N,N-dimethylformamide, and the dispersion liquid was homogenized using probe ultrasound to obtain a dispersion liquid.

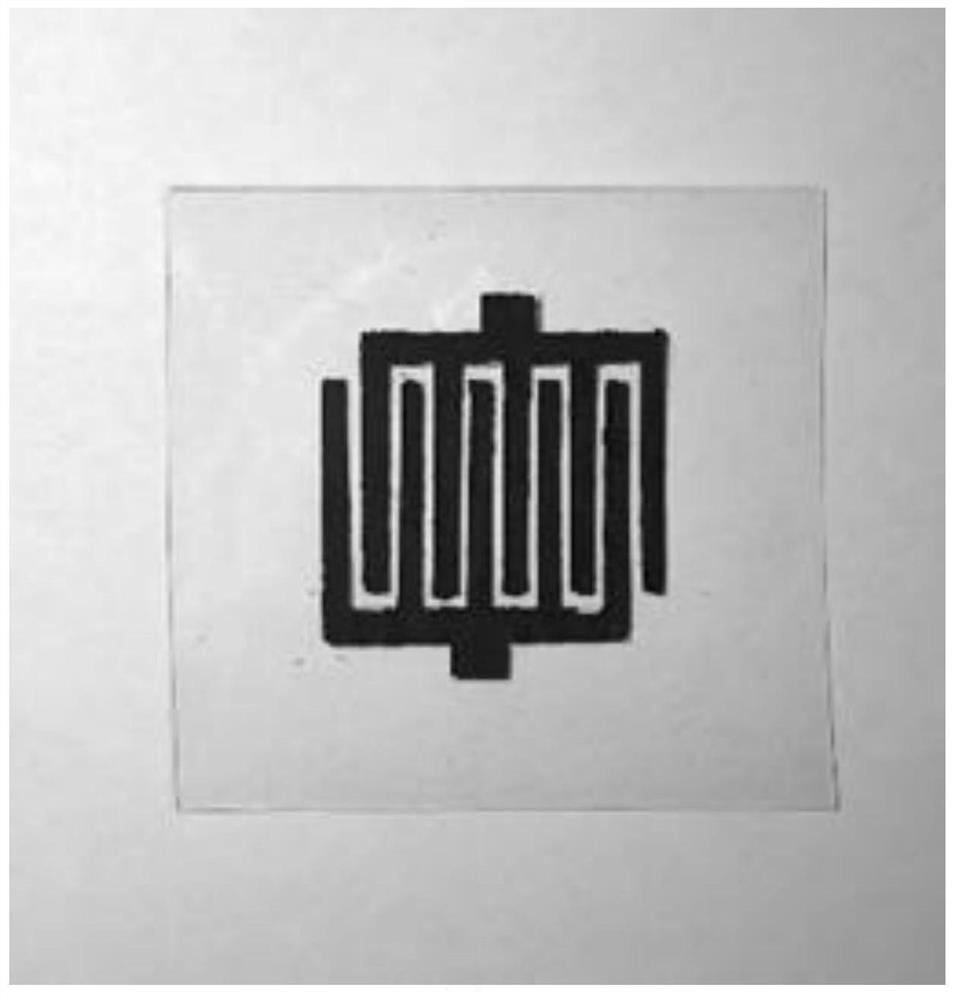

[0041] The organic membrane with a pore size of 0.22 microns is used as a filter membrane, and the electrode template with the shape of fingers (10 finger shapes, width 1.6mm, length...

Embodiment 3

[0043]Add 50 mg of 1,3,5-trimethyl-2,4-dicyanopyridine, 110 mg of 2,4,6-tris(p-formylphenyl)-1,3,5-triazine, 140mg of anhydrous piperidine and 15mL of anhydrous N,N-dimethylformamide were heated to 130°C for 40h under the protection of argon. After the reaction, the solid was collected by vacuum filtration, washed with dichloromethane and water, and the collected solid was vacuum-dried for 30 hours to obtain a yellow solid product, a nitrogen-rich covalent organic framework material linked by fully conjugated carbon-carbon double bonds.

[0044] 20 mg of the prepared covalent organic framework material and 10 mg of commercial single-walled carbon nanotubes were dispersed with 30 mL of N,N-dimethylformamide, and the dispersion liquid was homogenized by using probe ultrasound to obtain a dispersion liquid.

[0045] The organic membrane with a pore size of 0.22 microns is used as a filter membrane, and the electrode template with the shape of fingers (10 finger shapes, width 1.6m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com