Variable-spacing anti-light curtain and preparation method thereof

A variable pitch and curtain technology, applied in optics, instruments, projection devices, etc., can solve the problem that the reflective surface cannot fully function, and achieve the effects of saving raw materials, improving production efficiency, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

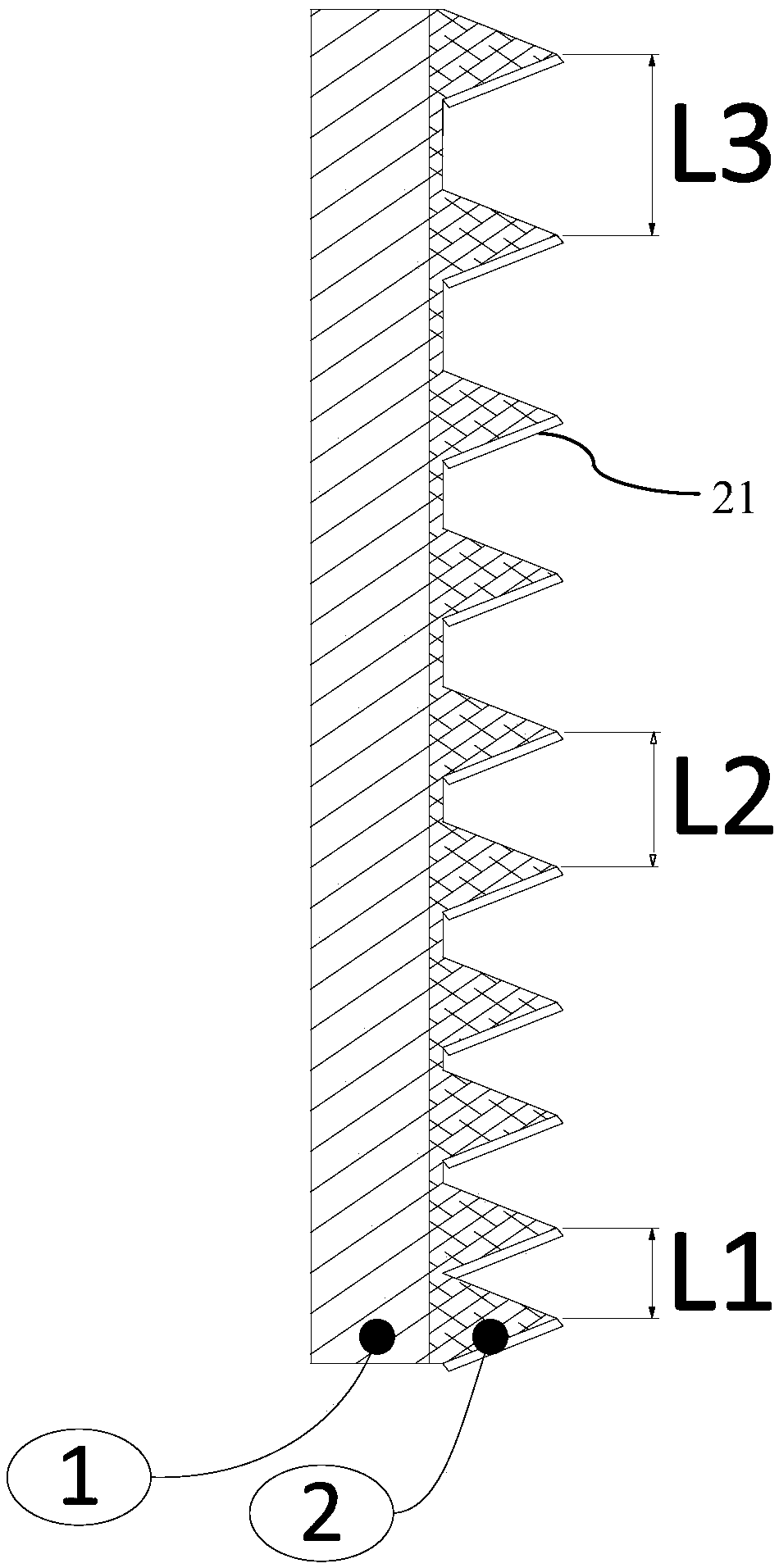

[0064] Figure 4 A schematic side view of a partial structure of the variable-pitch anti-light curtains of preferred embodiments 1 to 6 of the present invention is shown. The light-absorbing surface of the prismatic structure layer 2 is coated with a light-absorbing coating 22 . Table 1 shows the relevant parameters of the variable-pitch anti-light curtains of Examples 1-6.

[0065] The relevant parameters of the anti-light curtain of table 1 embodiment 1~6

[0066]

[0067]

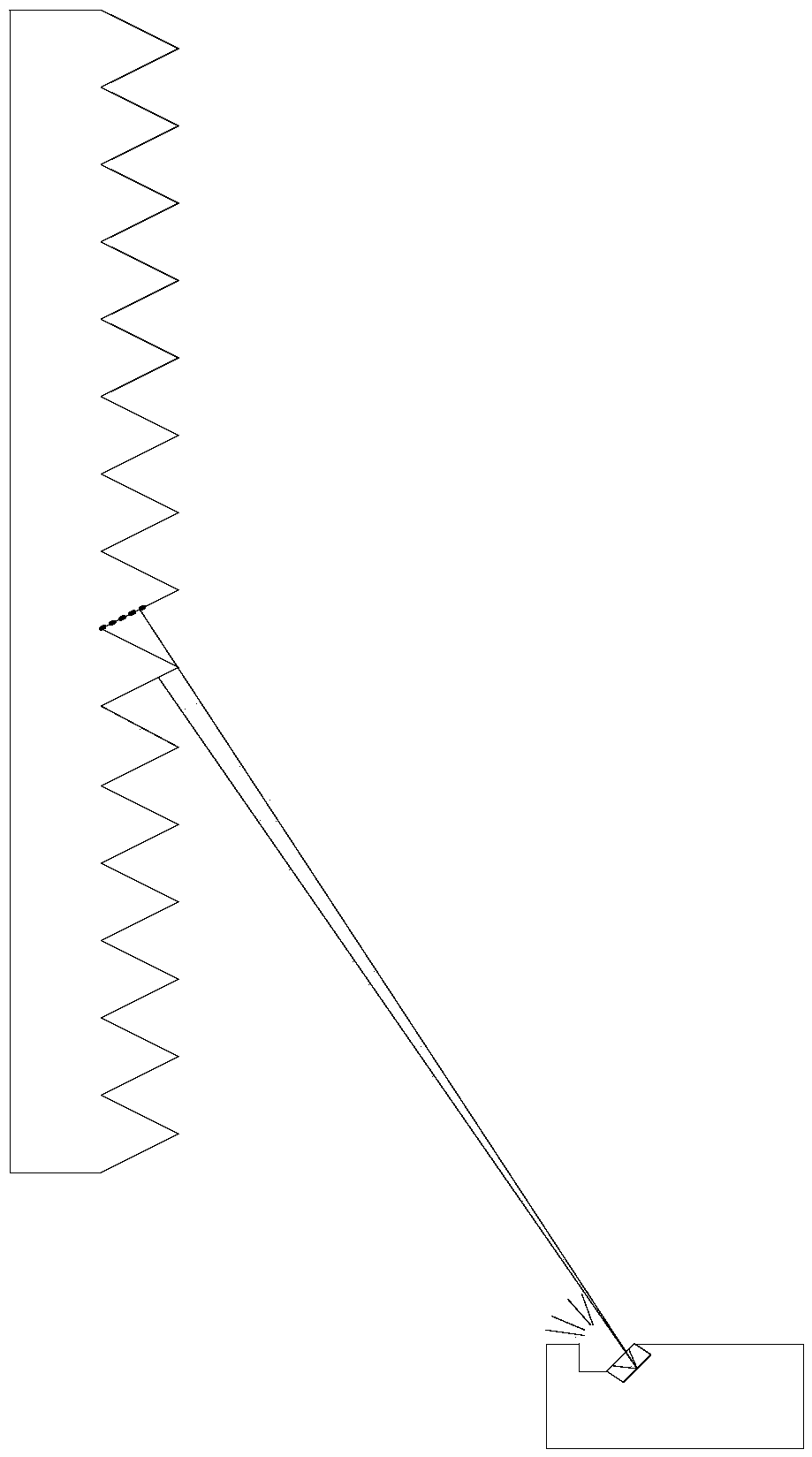

[0068] The preparation process of the variable-pitch anti-light curtain of Embodiment 1 to 6 of the present invention is as follows: Figure 5 As shown, the steps are as follows:

[0069] a) Manufacture the prismatic structure layer through hard mold and soft film technology: apply UV resin on the front of the substrate, and use a mold roller with a striped microstructure on the surface for rolling. During the rolling process, UV curing molding technology is used to coat the substrate. The UV re...

Embodiment 7~8

[0086] Image 6 Shows the local structural schematic diagram of the variable-pitch anti-light curtain of preferred embodiments 7 to 8 of the present invention, the light-absorbing surface of the prismatic structure layer 2 is made into a light-absorbing roughened microstructure 23, and the prismatic structure layer 2 is also uniform Black particles 24 are distributed, and the back of the substrate layer 1 is coated with a black light-absorbing layer 3 .

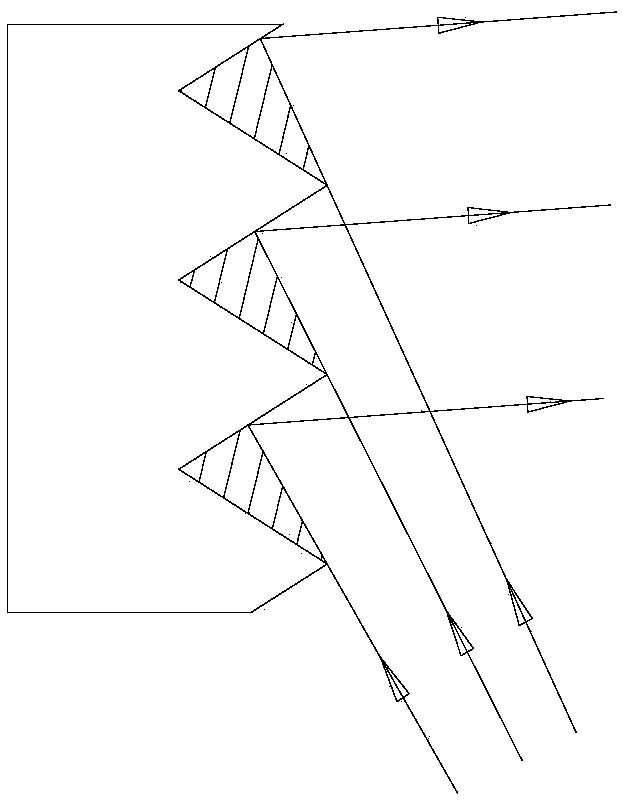

[0087] The surface roughness Rz value of the light-absorbing surface of the prismatic structure layer 2 (the sum of the maximum peak height and the maximum valley depth of the roughness profile) is 1 μm˜7 μm. Roughened microstructure of the light-absorbing surface as the first light-absorbing mechanism, such as Figure 7As shown, it can effectively absorb the light from the environment. Even if no light-absorbing material is coated, it can also reduce the reflected light from the environment to avoid affecting the imaging li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com