A kind of LED vacuum encapsulation process and vacuum pressing device

A vacuum packaging and vacuum pressing technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven distribution of fluorescent films, affecting luminous effects, and low production efficiency, so as to achieve good appearance consistency, improve production efficiency, The effect of stimulating light color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 , 2 , 3, and 5, a vacuum packaging process for LEDs, comprising the following steps:

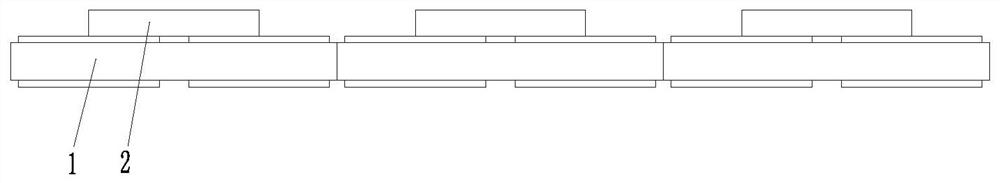

[0027] (1) Die bonding on the substrate 1, and the chip 2 is flipped on the substrate 1;

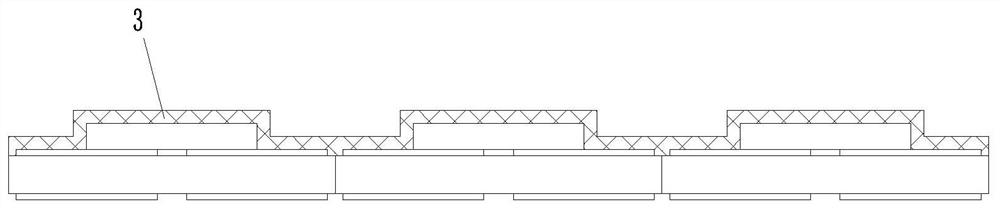

[0028] (2) Press the edge of the fluorescent soft film 3 on the substrate 1 in a vacuum environment, and the inner part of the fluorescent soft film 3 located at the pressed edge is not pressed, and the chip mounting area 4 is formed between the substrate 1 and the fluorescent soft film 3 ;

[0029] (3) Unload the vacuum;

[0030] (4) Baking and curing the fluorescent soft film 3;

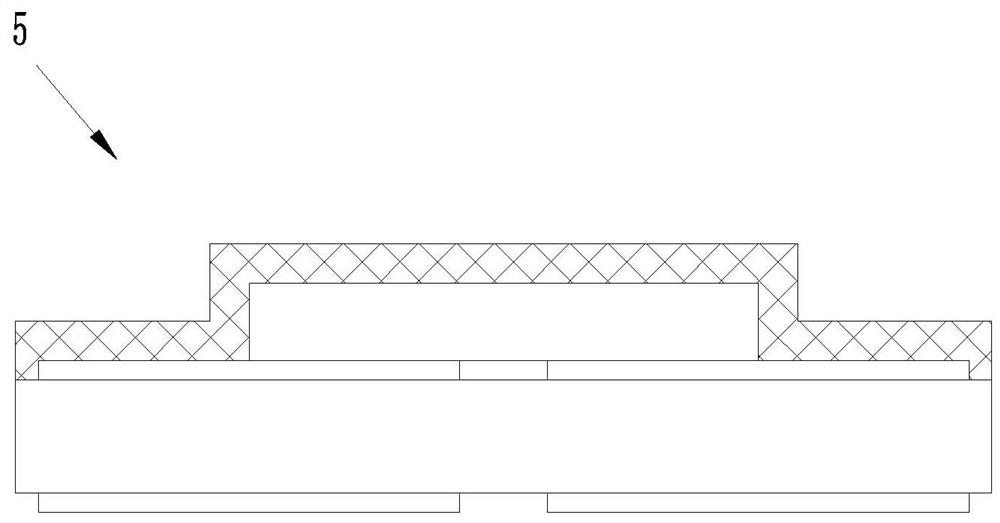

[0031] (5) Segmentation and cutting of the substrate 1 to form a single packaged LED 5 .

[0032] Such as Figure 4 As shown, the structure of the vacuum pressing device used in the above step (2) is as follows: the vacuum pressing device includes a vacuum chamber 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com