Battery pack pressure relief protection system, design method thereof and vehicle

A protection system and battery pack technology, applied in batteries, electric vehicles, vehicle energy storage, etc., can solve problems such as vehicle or personnel injury, battery system heat spread, limited space structure, etc., to avoid oxygen backflow, good flow direction, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

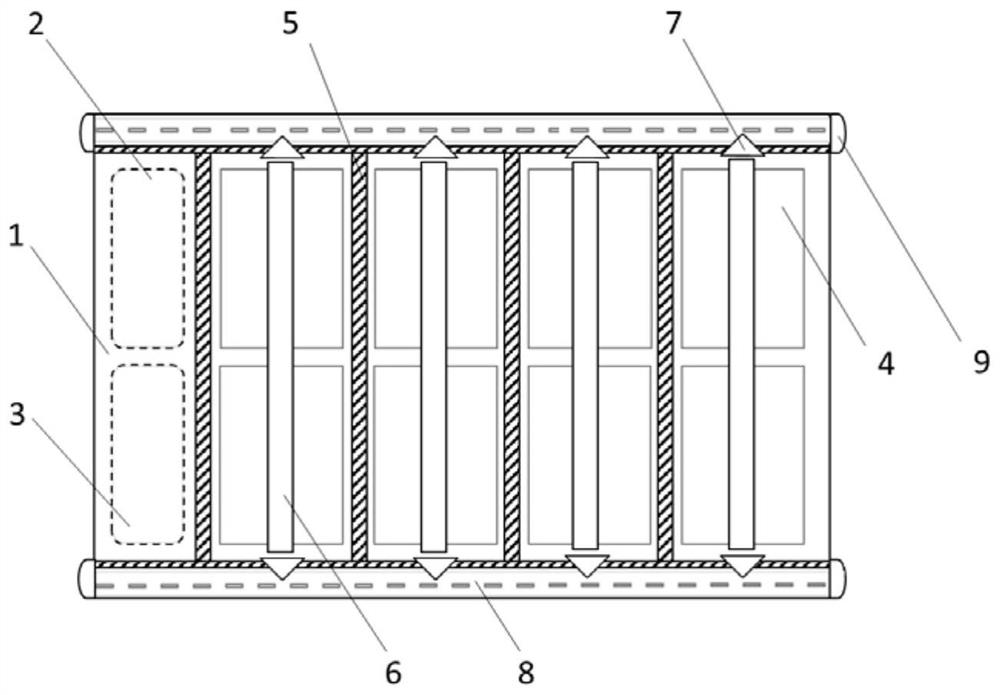

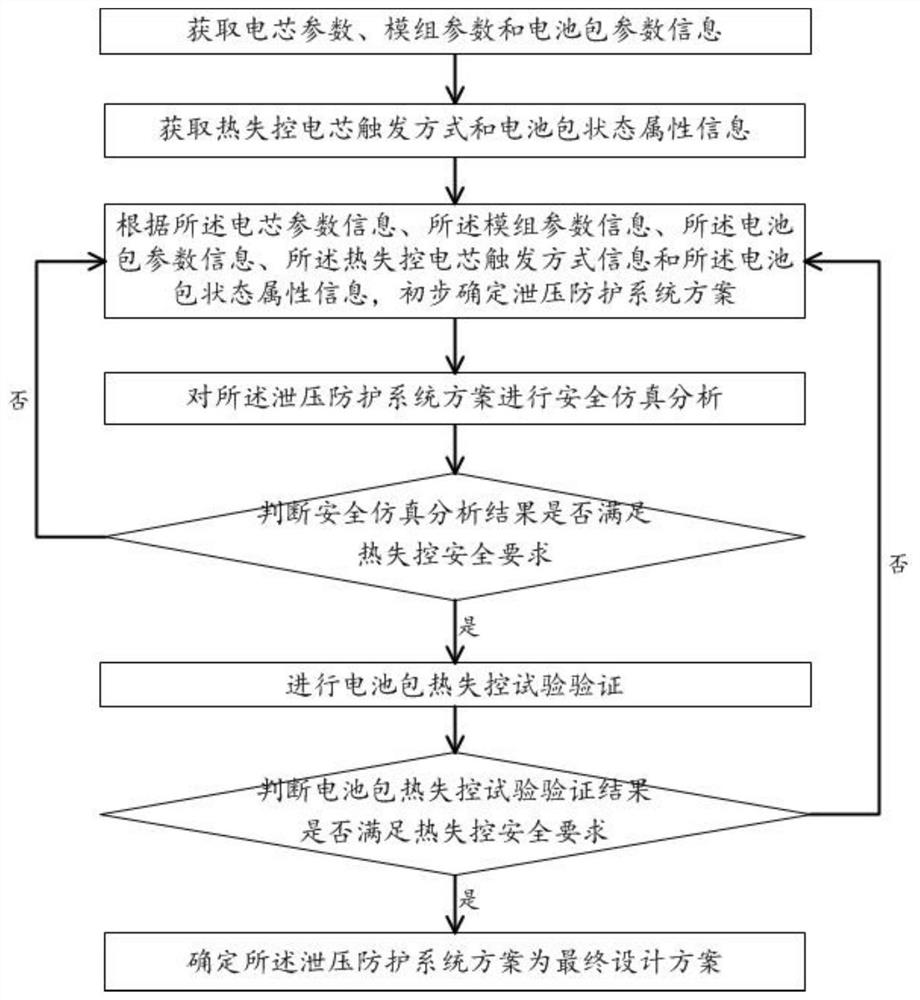

[0029] The existing technology provides a battery pack protection method, which sets up an independent combustion chamber for each module in the battery system. The combustion chamber is mainly made of fiber composite material and equipped with an independent explosion-proof structure. The explosion-proof structure is made of nylon Composite materials are the main material. In this method, the thermal runaway high-temperature gas flame of the battery core is controlled in the combustion chamber, and then evacuated to the outside of the box through the exhaust pipe and the explosion-proof structure.

[0030] Although the above method can slow down the spread of fire to a certain extent, there are still the following problems: (i) in the combustion chamber, the high-temperature flames generated by the thermal runaway of the battery cells will fill the upper space of the entire module, and the surface of the battery cells on the upper part of the module will be burnt. The heat sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com