Steel bar bundling structure and bundling method

A technology of steel bar and opening structure, which is applied to the parts and packaging of bundling machinery, can solve the problems of unsuitable steel bars, roughness, and difficulty in realizing the accumulation of steel bars, so as to achieve the effect of convenient bundling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

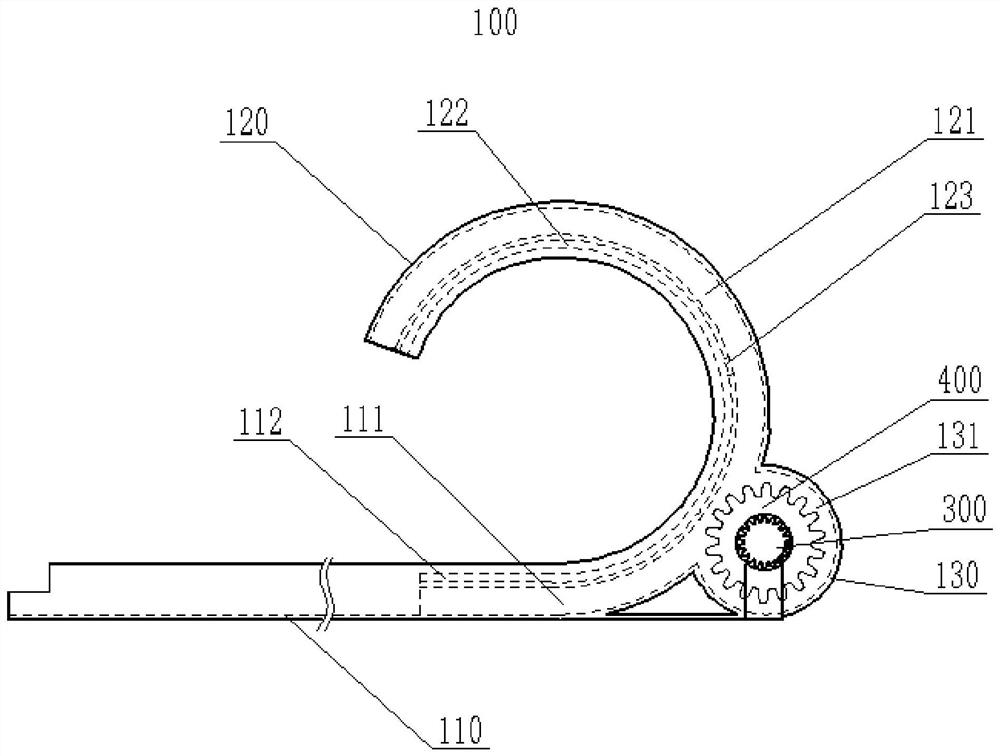

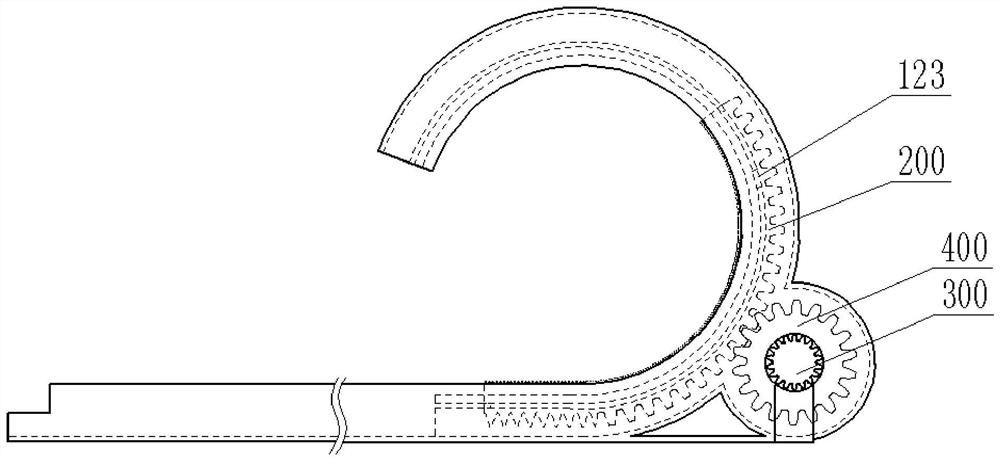

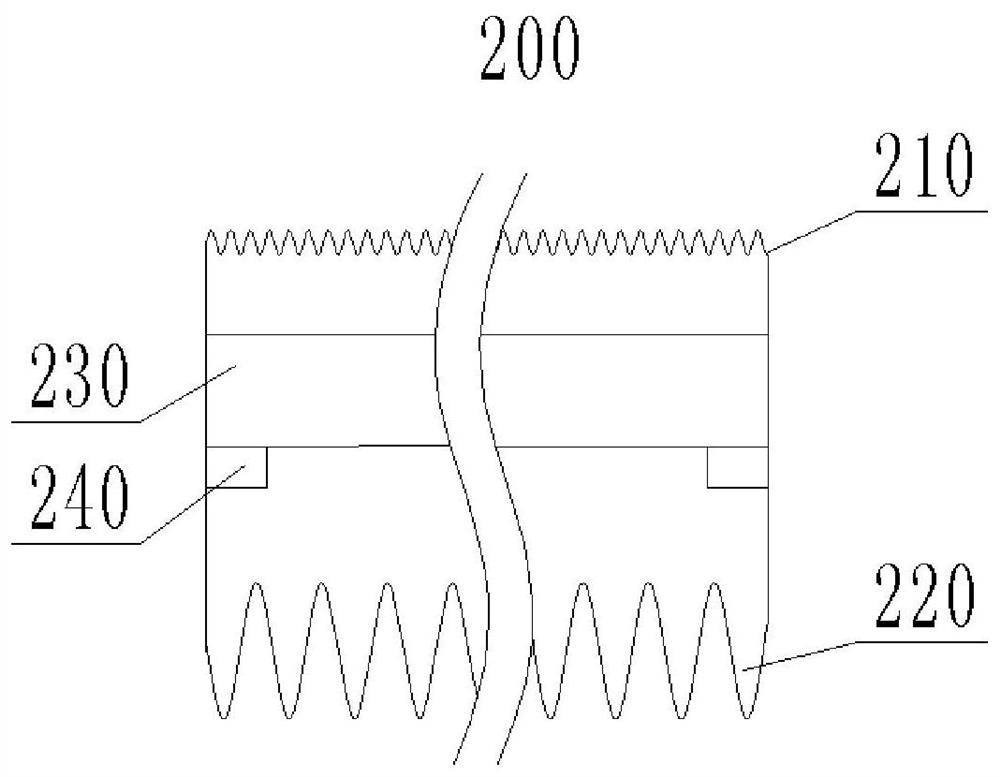

[0029] Such as figure 1 , 2 As shown, a steel bar binding structure includes a frame body 100, a driving strip 200, a binding assembly and a driving assembly; 120 connection, the upper surface of the docking bracket 110 is a smooth surface, and the regular bracket 120 is an arc-shaped structure; the docking bracket 110 and the regular bracket 120 are provided with accommodating chambers connected to each other, and the driving strip 200 can be movably installed In the accommodating cavity, the driving bracket 130 is provided with a driving cavity 131, the driving cavity 131 communicates with the accommodating cavity, the driving assembly is installed on the driving bracket 130, and the driving assembly drives the strip 200 in the accommodating cavity move; the upper surface of the docking support 110 near the end of the regular support 120 is an open structure, the contact surface between the regular support 120 and the steel bar is an open structure, and the driving strip 20...

Embodiment 2

[0035] Such as figure 1 , 2As shown, the accommodating cavity of the docking bracket 110 is a closed structure at one end away from the regular bracket 120, thereby facilitating the limitation of the starting position of the driving strip 200, and the accommodating cavity of the docking bracket 120 is open at one end away from the docking bracket 110. Structure, when in use, the driving strip 200 can extend out of the regular support 120, and when it extends to a certain extent, it can limit the height of the steel bars that are subsequently transported to the end of the docking support 110, or can help to regularize the steel bars that have already been located in the regular support 120, which is convenient for follow-up Bundle actions using bundle components.

Embodiment 3

[0037] In order to ensure that the driving strip 200 has enough space for movement, preferably, the length of the driving strip 200 is smaller than the length of the accommodation cavity. In order to avoid protruding out of the regular support 120 once the driving bar 200 moves, affecting subsequent use.

[0038] In the steel bar binding structure and binding method provided by the present invention, the drive assembly drives the belt bar 200 to generate displacement, so that the steel bars accumulated or gathered at the starting end of the belt bar 200 move to the root of the regular support 120, so that the aggregated shape of the steel bars tends to be arc-shaped and because the upper surface of the docking support 110 is a smooth surface, after the driving bar 200 shifts, the reinforcing bar will continue to move towards the root of the regular support 120 under the thrust of the follow-up reinforcing bar, thereby facilitating the use of a binding structure to bind the rein...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap