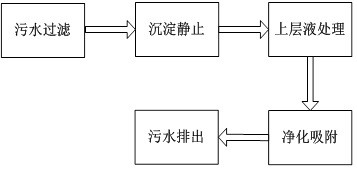

Water-based paint production wastewater post-treatment process

A technology for the production of wastewater and water-based coatings, which is applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of impurities easily accumulating on the surface of the biofilm and damage to the biofilm , can not be protected by biological membranes, etc., to avoid waste water pollution of the environment, prevent secondary pollution, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

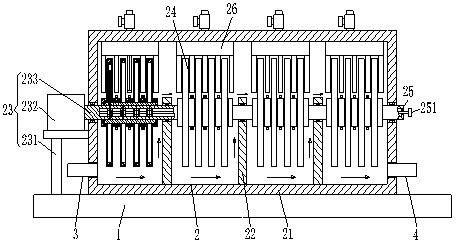

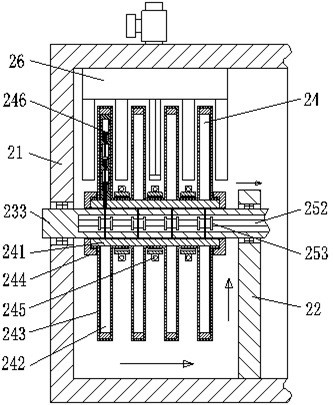

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0034] Such as Figure 1 to Figure 6 As shown, a water-based paint production wastewater post-treatment process, the water-based paint production wastewater post-treatment process adopts the following processing equipment, the processing equipment includes a base plate 1, a filter device 2, a liquid inlet pipe 3 and a liquid discharge pipe 4, the described A filter device 2 is installed in the middle part of the upper end of the bottom plate 1, a liquid inlet pipe 3 is installed at the left lower end of the filter device 2, and a liquid discharge pipe 4 is installed at the right lower end of the filter device 2.

[0035] Described filtering device 2 comprises housing frame 21, dividing plate 22, driving mechanism 23, purifying mechanism 24, adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com