Hybrid magnetic suspension knitting needle driving device and control method thereof

A driving device and magnetic levitation technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of small axial displacement of knitting needles, complicated control process, long response time, etc., to achieve simple control, simplified control process, The effect of reducing the response time of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

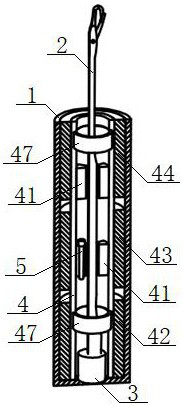

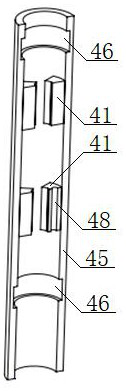

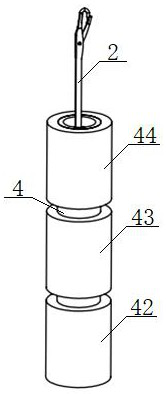

[0049] see Figure 1 to Figure 5 , a hybrid magnetic suspension knitting needle drive device, including a housing 1 and a knitting needle 2, the housing 1 is a cylindrical structure, the head of the knitting needle 2 is composed of a needle head and a needle latch, and the knitting needle 2 The middle section is rectangular, the bottom of the knitting needle 2 is a cylindrical permanent magnet 3, and the casing 1 is provided with a bobbin 4, the bobbin 4 is a cylindrical structure, and the inner circumference of the bobbin 4 is along the coil Two radial support blocks 41 are symmetrically arranged on the central axis of the frame 4, and an optical fiber displacement sensor 5 is installed on the radial support block 41, and the optical fiber displacement sensor 5 is connected with the signal of the control system. A primary coil 42, a secondary coil 43, and a tertiary coil 44 are respectively wound on the outer peripheral surface of the upper part. The primary coil 42, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com