Rapid tamping device and construction method

A compaction device and fast technology, applied in the field of building foundation, can solve the problems of shortening construction time, accelerating foundation compaction, low technical requirements, etc., to achieve the effect of improving work efficiency and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

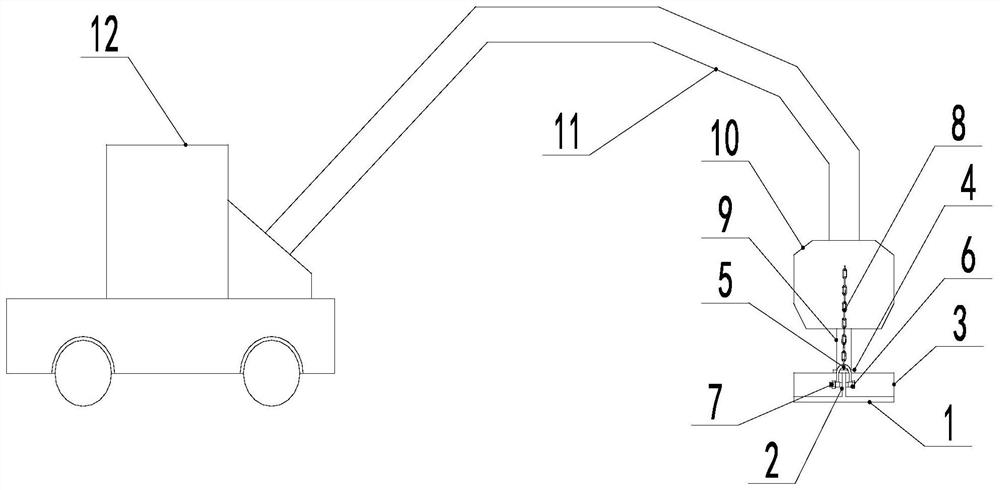

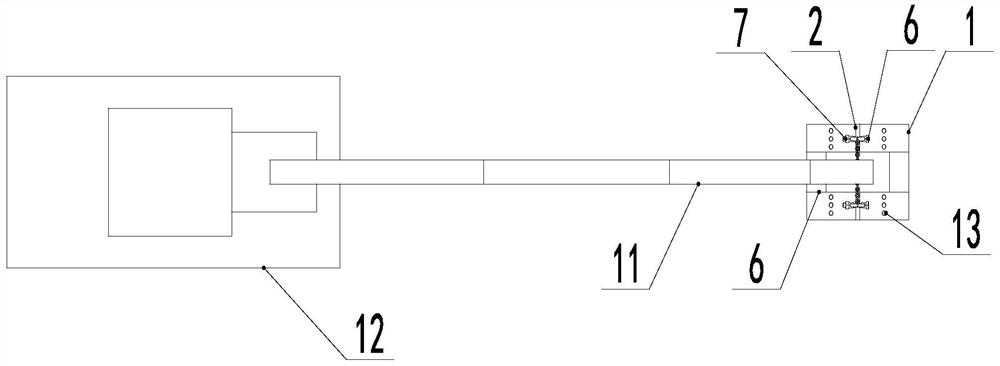

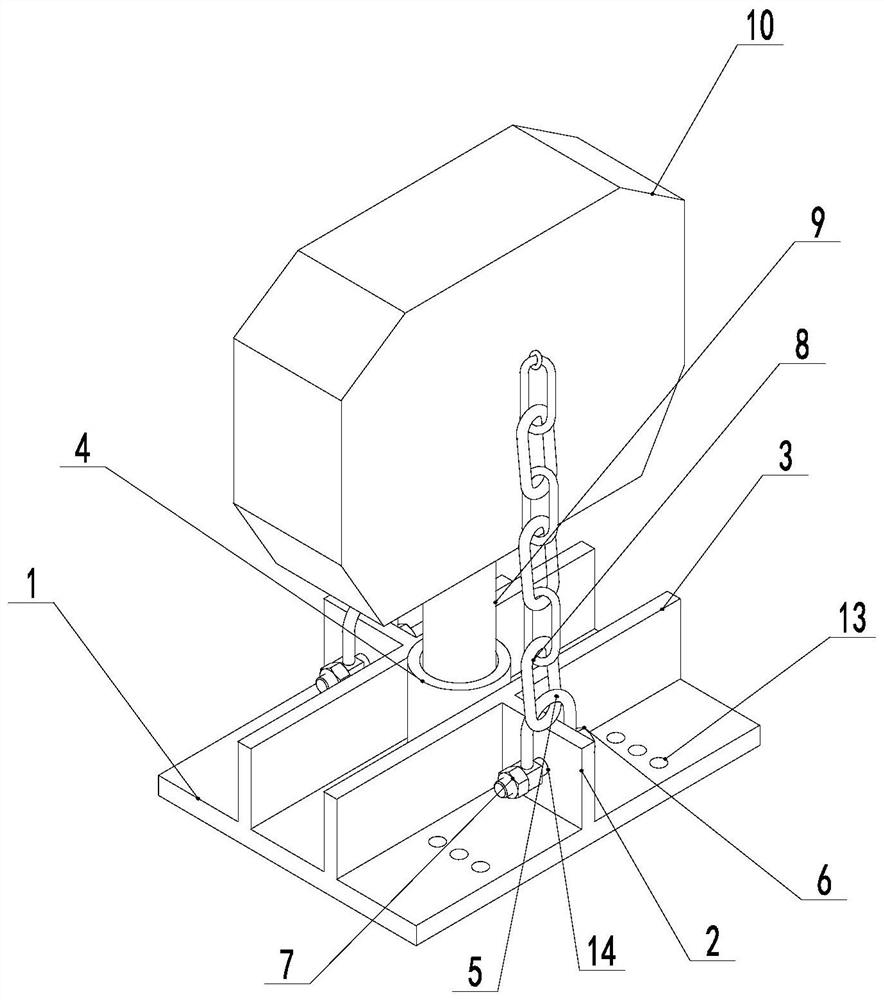

[0029] Such as figure 1 , 2 , 3, a rapid compaction device and method, comprising a compaction plate 1, a lifting plate 2, a reinforcement plate 3, a positioning cylinder 4, a connecting buckle 5, a bolt 6, a nut 7, an iron chain 8, a connecting hammer head 9, an impact Drill 10, the upper half and lower half of the tamping plate 1 are processed with exhaust pressure relief holes 13, and the exhaust pressure relief holes 13 are distributed on the upper and lower sides of the tamping plate 1, so that the tamping can be eliminated during the tamping operation. The air between the plate 1 and the foundation reduces the air resistance during the tamping process, which is beneficial to fully apply the tamping force to the foundation and improve the quality of tamping. The middle position of the tamping plate 1 is welded with the positioning cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com