LNG multi-stage immersed pump

A submersible pump and pump casing technology, applied in the field of LNG multi-stage submersible pumps, can solve the problems of uneven operation of the pump, axial slippage of the shaft sleeve and the snap ring, etc., so as to reduce the error and ensure the circumferential positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0030] For the convenience of description, the figure 1 The left end is the front, and the right end is the back.

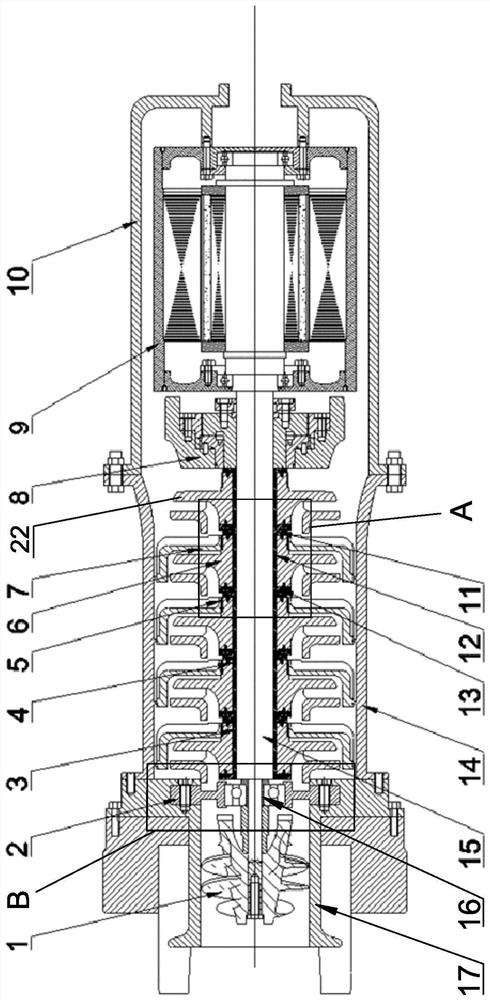

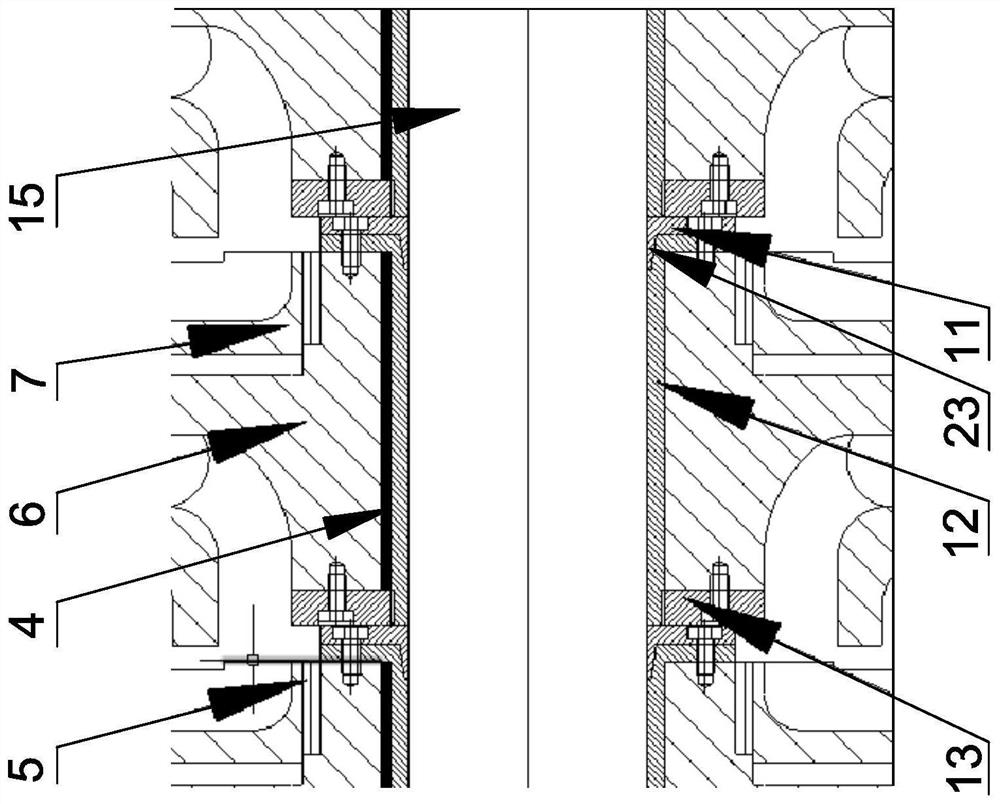

[0031] Such as figure 1 The LNG multi-stage submersible pump shown includes coaxially arranged front section pump casing 17, middle section pump casing 14, rear section pump casing 10, bearing assembly 2, built-in motor 9, pump shaft 15, inducer 1, several (Fig. Show five) impeller 6, some (show four in the figure) guide vane 7 and balance disk 8. The front pump casing, the middle pump casing and the rear pump casing are arranged in sequence from front to back and are fixedly connected by bolts. The front end of the front pump casing is provided with an inlet, and the rear end of the rear pump casing is provided with an outlet.

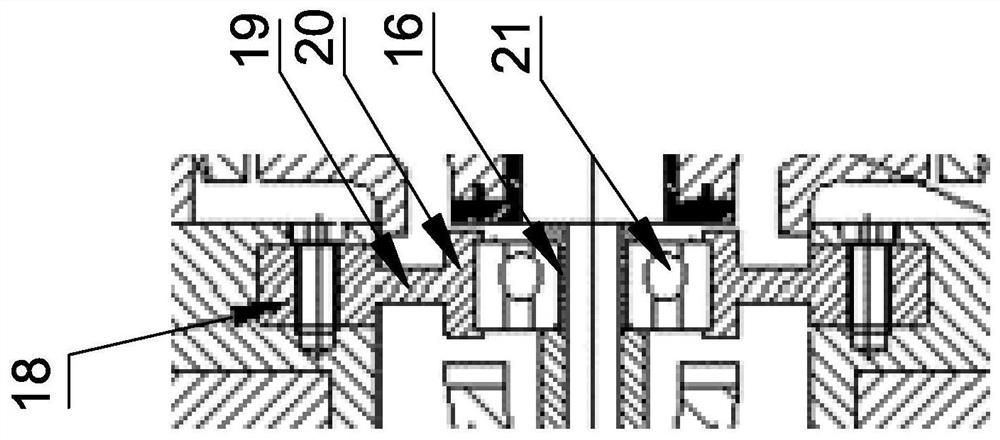

[0032] Such as figure 1 , image 3 As shown, the bearing assembly is arranged in the front pump casing; wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com