Built-in type weft-direction reinforced metal honeycomb structure and manufacturing method thereof

A metal honeycomb and manufacturing method technology, applied in metal processing equipment, sheets/boards, building elements, etc., can solve the problem that the connection strength is difficult to reach extremely high, achieve strong structural strength in all directions, reduce production costs, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

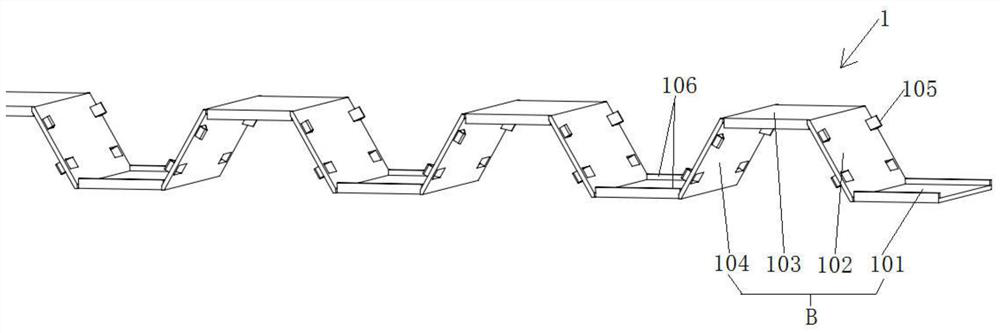

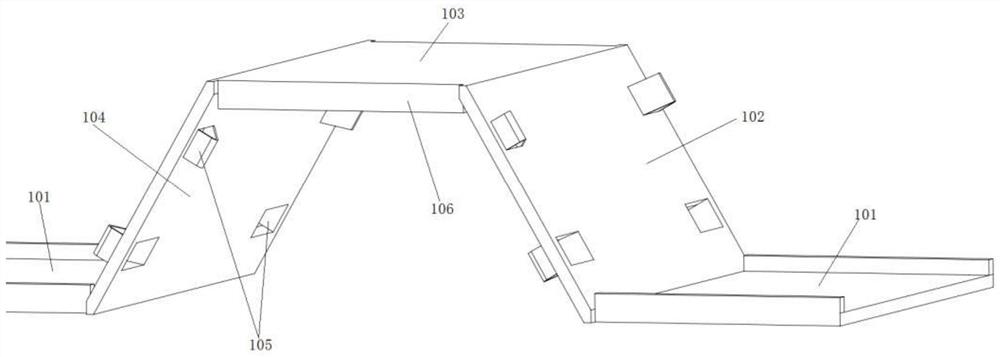

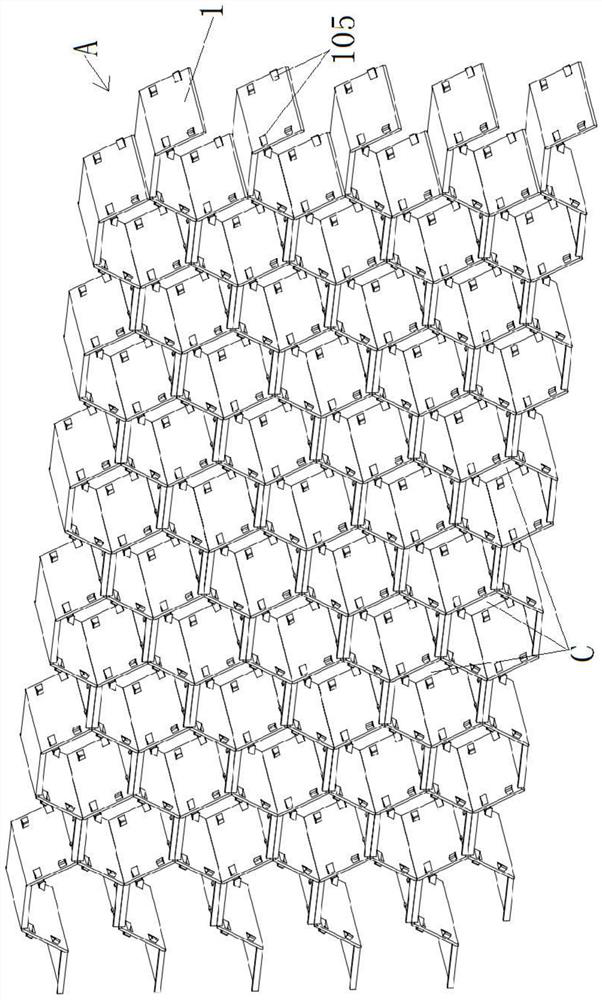

[0066] see Figure 1 to Figure 11 , an embedded latitudinal reinforced metal honeycomb structure, comprising a honeycomb core A, the honeycomb core A has a plurality of trapezoidal bars 1 arranged parallel to each other, each trapezoidal bar 1 extends along the warp direction, and the trapezoidal bars 1 have A plurality of unit sections B connected end to end in sequence, the unit section B is composed of a first bottom plate 101, a first waist plate 102, a second bottom plate 103 and a second waist plate 104 which are integrally connected in sequence, the first waist plate 102 and the second waist plate The waist plate 104 is symmetrically distributed at both ends of the second bottom plate 103; the first bottom plate 101 and the second bottom plate 103 of adjacent trapezoidal strips 1 are fixedly connected to form a honeycomb core A with multiple cells; it also includes at least two embedded Board 2, the inner panel 2 extends along the weft direction and is perpendicular to ...

Embodiment 2

[0085] Repeat embodiment 1, the difference is only: the non-working surface of the present embodiment is provided with a plurality of holes 10 on the inner panel, and the plurality of holes are distributed sequentially along the length direction of the inner panel; the diameter of the hole is 15mm round hole.

[0086] On the one hand, the setting of the hole can play a role in reducing weight, on the other hand, it can be used as a process hole to facilitate the electrode head of the resistance welding machine to enter the cell, and spot weld the connection platform between the inner panel and the trapezoidal strip on the non-working surface .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com