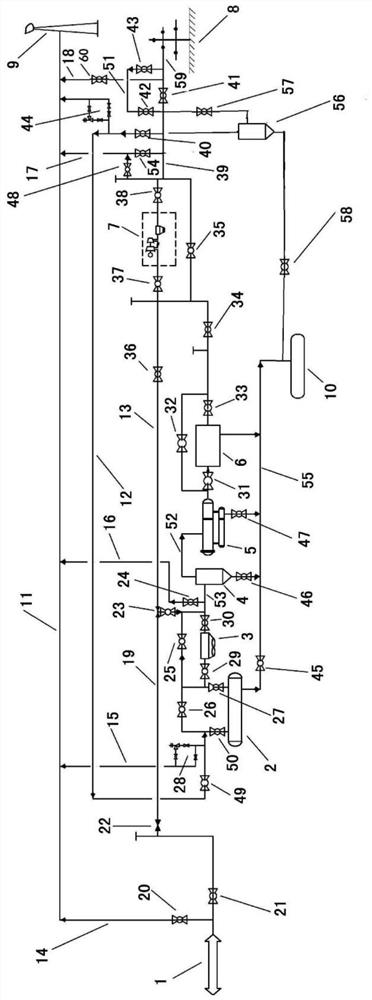

Ground gathering and transportation system for depleted gas reservoir gas storage

A technology of gathering and transportation system and gas storage, which is applied in the field of surface process and equipment to achieve the effect of delaying the formation speed, reducing liquid accumulation and eliminating slug flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The preparation method of the hydrate inhibitor comprises the following steps,

[0064] Step 1: Add 0.1 mol of N-dimethylaminomethacrylate, 0.05 mol of 2-vinyl-4,6-diamino-1,3,5-triazine, 0.05 mol of 1,3-divinyl- 0.05 mol of 2-imidazolinone and 200 ml of deionized water were added, and an emulsifier was added, and the temperature was raised to 70°C under the protection of nitrogen, and mixed uniformly to obtain a mixed solution A. The emulsifier is a composition of SDS and AEO-9, and the mass of both SDS and AEO-9 is 0.11g.

[0065] Step 2: Dissolve 0.1g of potassium persulfate in 18ml of deionized water, slowly add it dropwise to the mixed solution A obtained in step 1 after the dissolution is completed, and continue the reaction for 5 hours after the dropwise addition is completed.

[0066] Step 3: After the reaction is completed, the condensate is filtered, centrifuged, and dried to obtain a solid product, which is the prepared product.

Embodiment 2

[0068] The preparation method of the hydrate inhibitor comprises the following steps,

[0069] Step 1: Add 0.3mol of N-dimethylaminomethacrylate, 0.15mol of 2-vinyl-4,6-diamino-1,3,5-triazine, 0.15mol of 1,3-divinyl- 0.15 mol of 2-imidazolidinone and 200 ml of deionized water were added, and an emulsifier was added, and the temperature was raised to 70° C. under the protection of nitrogen, and mixed uniformly to obtain a mixed solution A. The emulsifier is a composition of SDS and AEO-9, and the quality of both SDS and AEO-9 is 0.15g.

[0070] Step 2: Dissolve 0.1g of potassium persulfate in 18ml of deionized water, slowly add it dropwise to the mixed solution A obtained in step 1 after the dissolution is completed, and continue the reaction for 5 hours after the dropwise addition is completed.

[0071] Step 3: After the reaction is completed, the condensate is filtered, centrifuged, and dried to obtain a solid product, which is the prepared product.

Embodiment 3

[0073] The preparation method of the hydrate inhibitor comprises the following steps,

[0074] Step 1: Add 0.5 mol of N-dimethylaminomethacrylate, 0.3 mol of 2-vinyl-4,6-diamino-1,3,5-triazine, 0.3 mol of 1,3-divinyl- 0.3 mol of 2-imidazolinone and 200 ml of deionized water were added, and an emulsifier was added, and the temperature was raised to 70°C under the protection of nitrogen, and mixed uniformly to obtain a mixed solution A. The emulsifier is a combination of SDS and AEO-9, both of which have a mass of 0.21 g.

[0075] Step 2: Dissolve 0.1g of potassium persulfate in 18ml of deionized water, slowly add it dropwise to the mixed solution A obtained in step 1 after the dissolution is completed, and continue the reaction for 5 hours after the dropwise addition is completed.

[0076] Step 3: After the reaction is completed, the condensate is filtered, centrifuged, and dried to obtain a solid product, which is the prepared product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com