Wire sensor and monitoring system for dangerous rock monitoring

A pull wire sensor and pull wire technology, applied in the field of pull wire sensors, can solve the problems of high battery risk, short continuous use time, and insufficient accuracy, and achieve the effect of prolonging the voyage time, increasing the voyage time, and increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

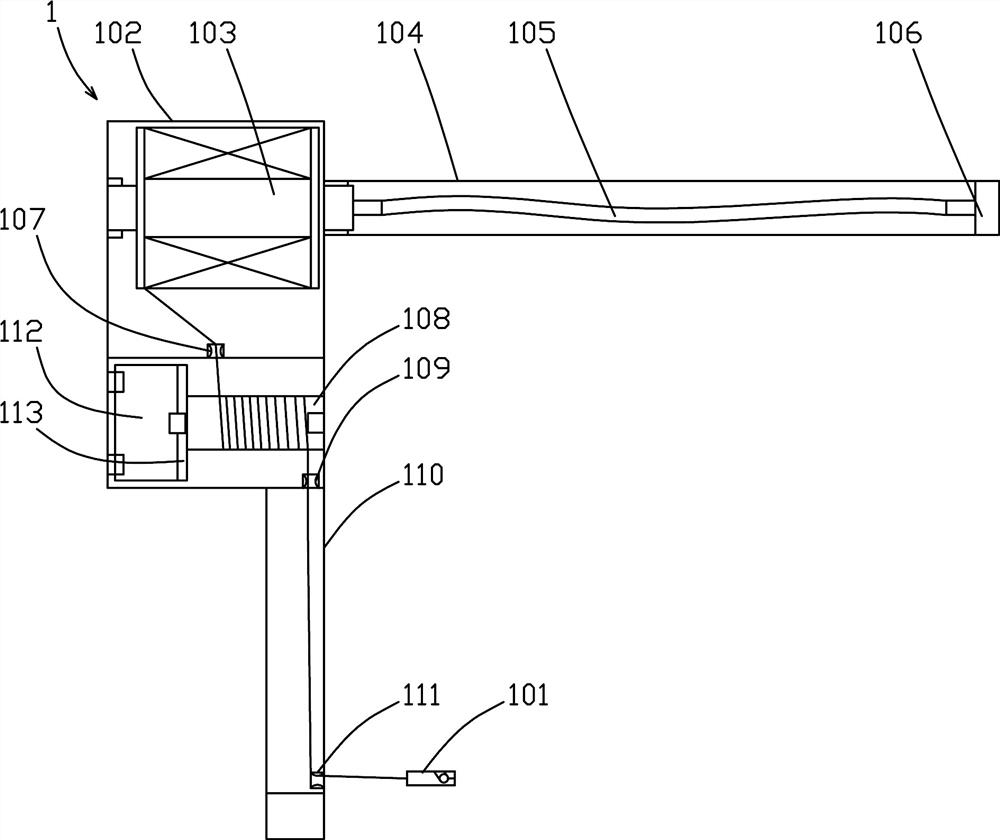

[0033] Such as Figure 1~6 Among them, a cable sensor for dangerous rock monitoring, which includes a winding wheel 103 and a cable rotating roller 108;

[0034] Such as image 3 As shown in , the winding wheel 103 is rotatably supported in the housing 102, the winding wheel 103 is used to wind the backguy 5, the winding wheel 103 is connected with the elastic device, so that the winding wheel 103 will pull the backguy 5 in one direction Tension;

[0035] The backguy roller 108 is rotatably supported in the housing 102, and the backguy 5 drawn from the winding wheel 103 is wound multiple times on the backguy roller 108, and is drawn out of the housing 102. Corner reading device. With this structure, by adopting the scheme that the winding wheel 103 and the wire-drawing roller 108 are separately arranged, the backguy will only be wound on one layer on the wire-drawing roller 108 all the time, thereby overcoming the problem in the prior art that the wire is wound on the wire-...

Embodiment 2

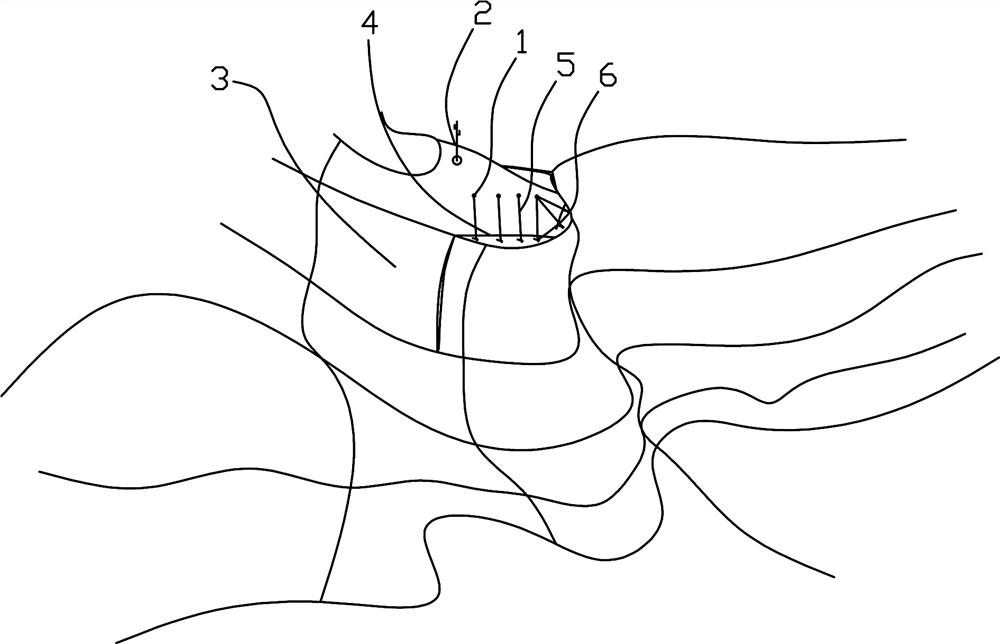

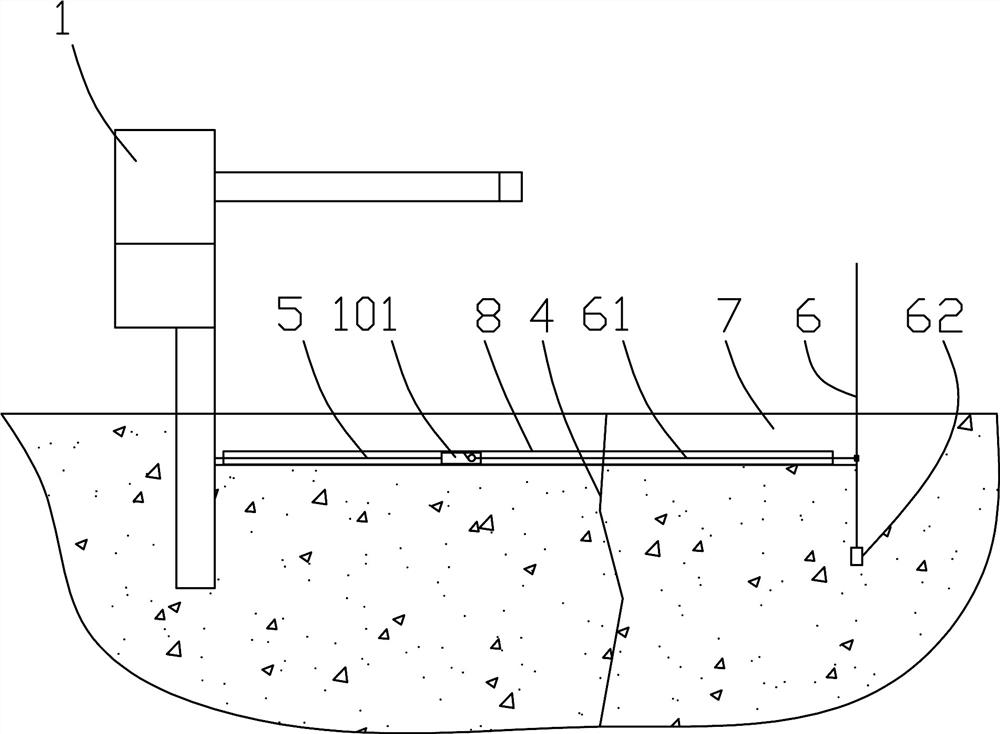

[0047] Such as figure 1 , 2 Among them, a monitoring system using the above-mentioned guy sensor for dangerous rock monitoring, it includes a guy sensor 1 and an anchor rod 6, the guy sensor 1 is fixed on the foundation side of the dangerous rock 3, and the anchor rod 6 is fixed on the dangerous rock 3 on the slip side;

[0048] One end of the connecting wire rope 61 is fixedly connected with the anchor rod 6, and the other end of the connecting wire rope 61 is fixedly connected with the connector 101 of the pull wire sensor 1;

[0049] An excavation groove 7 is arranged between the pull wire sensor 1 and the anchor rod 6 , the protection tube 8 is arranged in the excavation groove 7 , and the connecting wire rope 61 and the stay wire 5 penetrate into the protection tube 8 . Dangerous rock 3 in a certain place is mainly limestone, which is a hard rock with strong karstification. The weak base under the second-order cliff is the shale of the second member of the Maokou Format...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com