Non-scanning demodulation system based on optical fiber Fabry-Perot sensor

A Faber sensor and demodulation system technology, which is applied in the field of optical fiber sensing, can solve the problems of increasing the contrast of the effective demodulation signal, uneven distribution of signal light energy, and the influence of the contrast of the demodulation signal, so as to improve the effective demodulation signal. Contrast, increase the utilization of light intensity, avoid the effect of chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

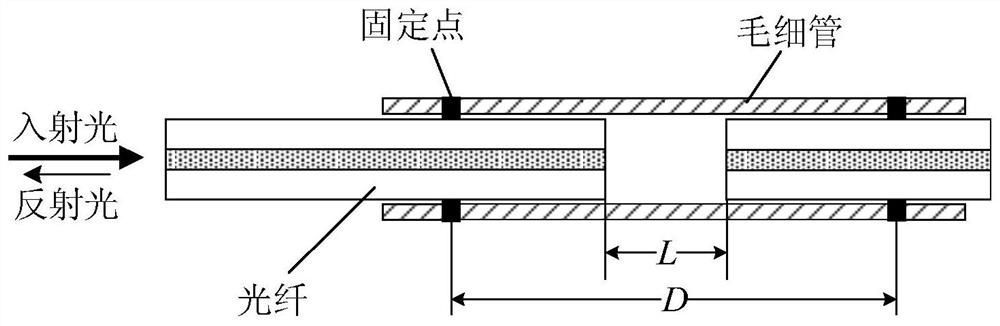

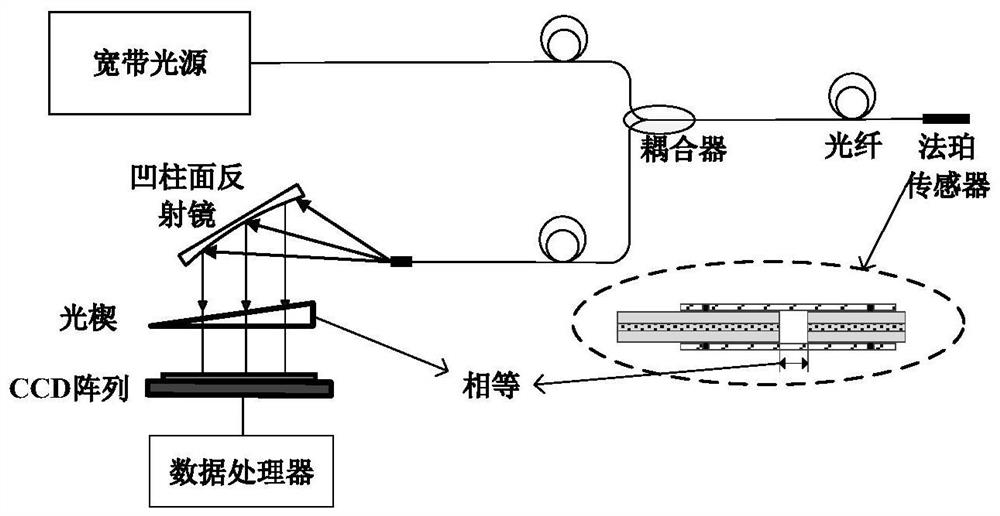

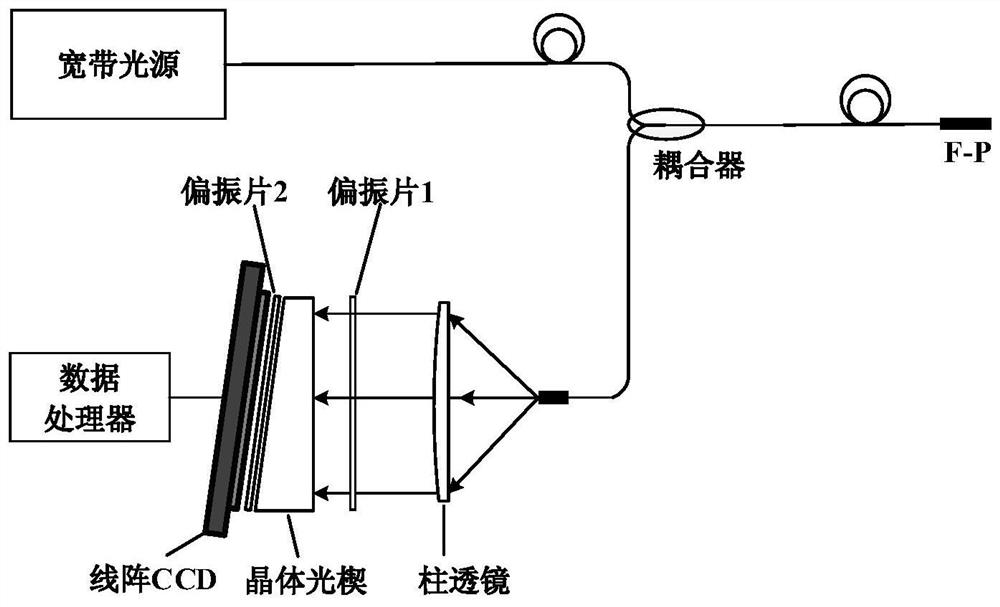

[0041] Such as Figure 4 As shown, the non-scanning demodulation system based on the optical fiber Fabry-Perot sensor of the present invention includes: a positive lens, a first free-form surface mirror, a second free-form surface mirror, an optical wedge, a plano-convex cylindrical lens, and a linear array CCD, data processor, optical fiber Fabry Perot sensor and coupler;

[0042] The positive lens is used to receive the light with cavity length information obtained from the optical fiber Fabry-Perot sensor, the light is emitted to the positive lens through the optical fiber, and the light is diverged into parallel light; the first free-form surface mirror is used to receive the positive lens The divergent parallel light is converted into flat-top light; the second free-form surface mirror is used to collimate the exit direction of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com