Locally heat-treated and hardened screw

A local quenching and screw technology, used in heat treatment furnaces, heat treatment equipment, screws, etc., can solve problems such as screw head fracture, screw deformation, and sudden head breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

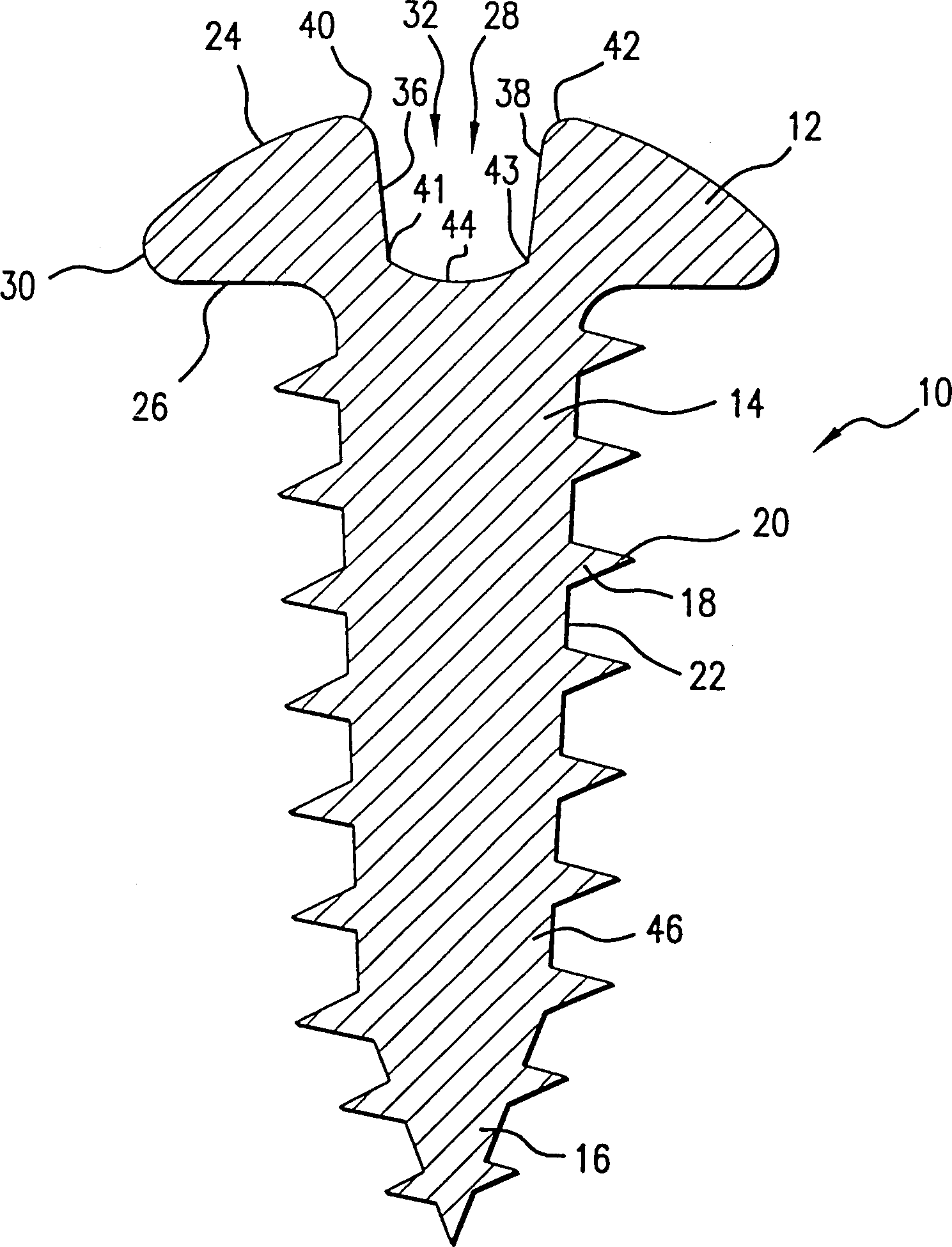

[0020] refer to figure 1 The carbon steel screw 10 of the present invention has a head 12, a screw portion 14 below the head and a screw point 16 at one end of the screw portion opposite the head. A plurality of threads or threads 18 having cusps 20 and interdental grooves 22 wrap around the screw portion 14 and screw tip 16 .

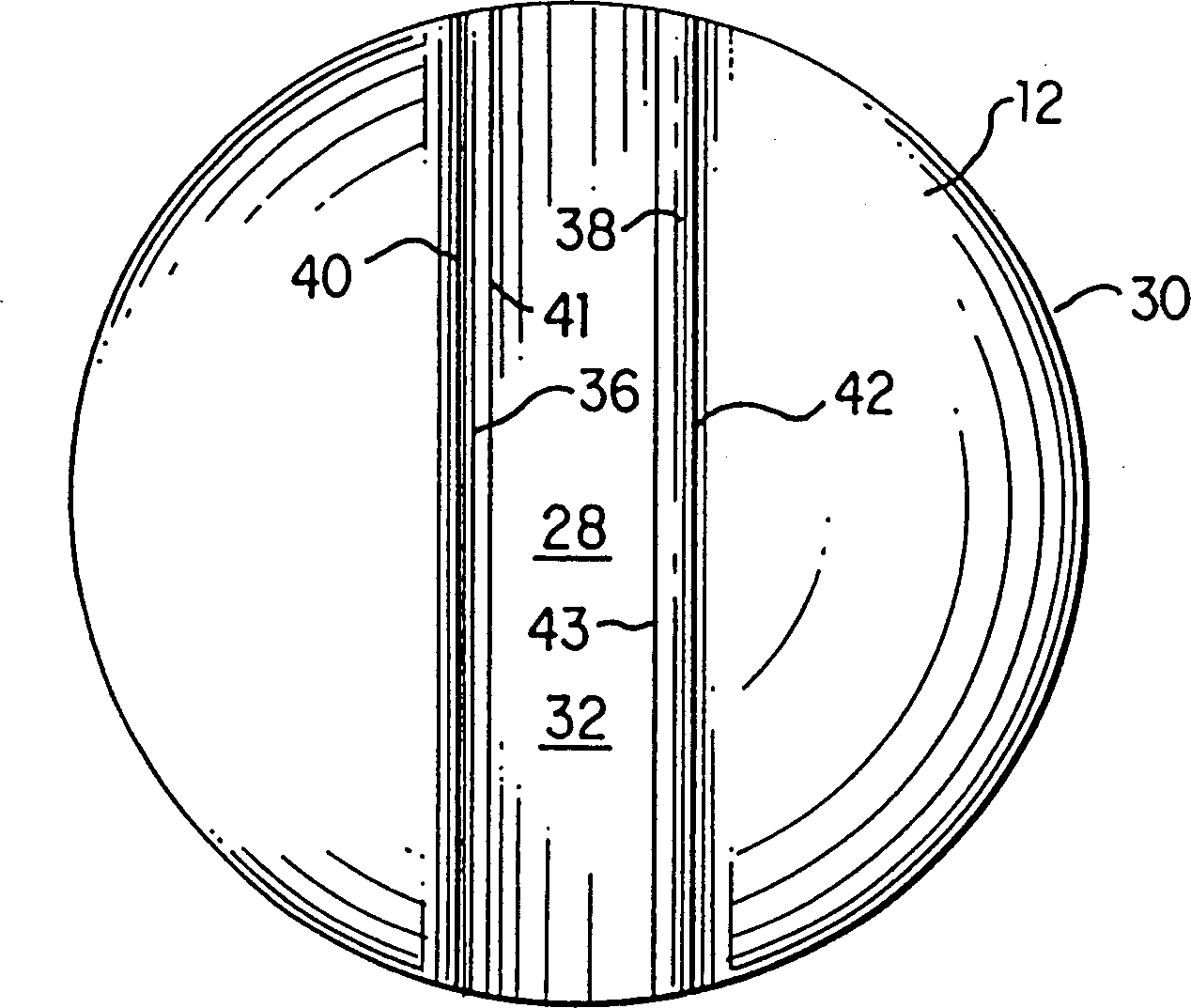

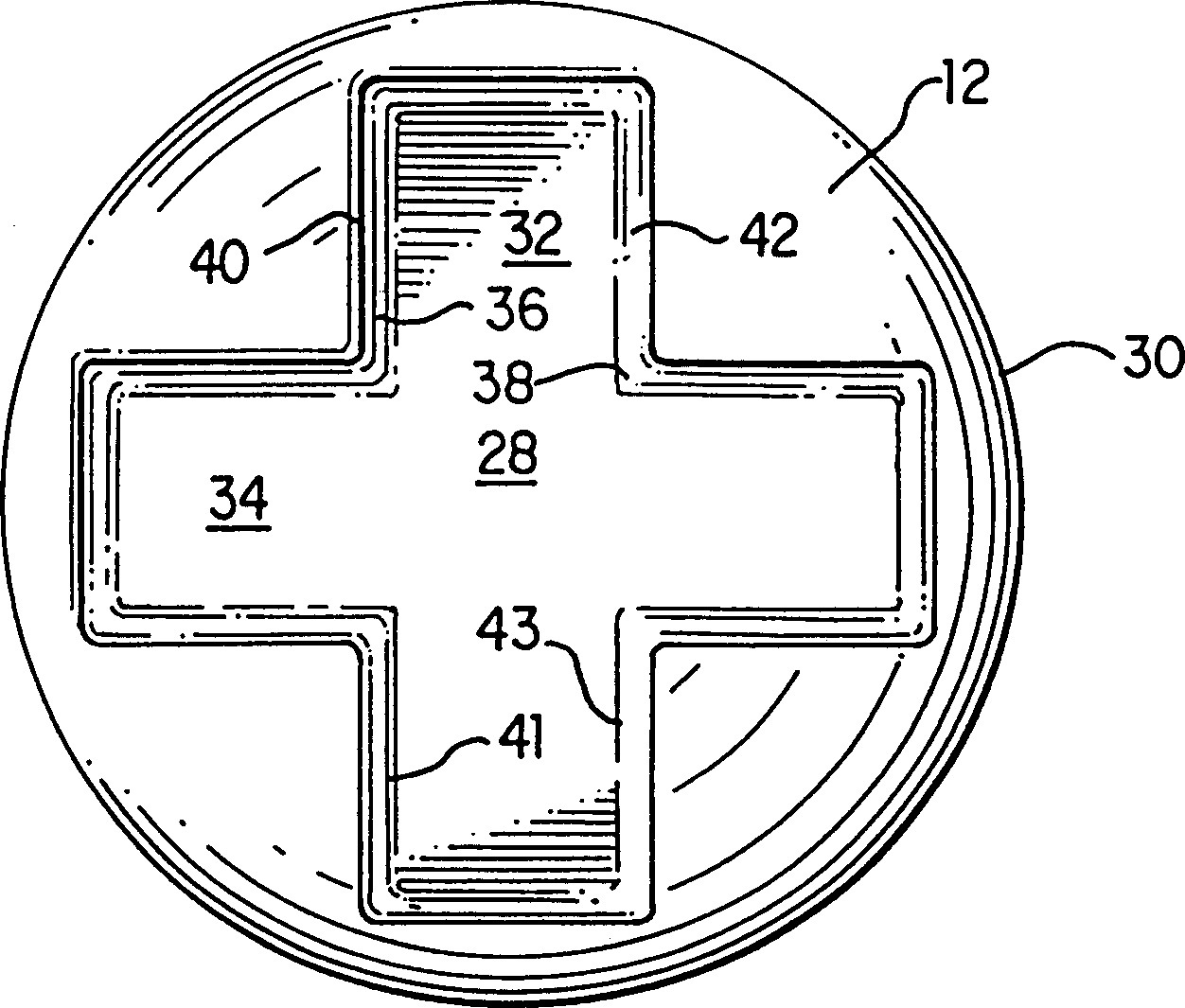

[0021] refer to Figure 1-3 , the head 12 has a top surface 24 , a bottom 26 , a central region 28 and an outer rim 30 . The central area 28 includes an in-line recess 32 suitable for receiving a standard screwdriver or similar driving tool or suitable for receiving a Phillips TM A pair of intersecting grooves 32 and 34 of a screwdriver or similar driving tool designed for cross-shaped grooves.

[0022] Each groove is defined by a pair of opposed generally upstanding walls 36 and 38 which intersect top surface 24 at edges 40 and 42 and groove bottom 44 at intersection lines 41 and 43 . The groove depth is the distance between the edges 40 and 42 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com