Washing process and preparation method of a high-nickel polycrystalline ternary positive electrode material

A cathode material and high-nickel technology, which is applied in the washing process and preparation field of high-nickel polycrystalline ternary cathode materials, can solve problems such as loss of gram capacity, poor cycle performance, and large specific surface area, so as to improve processing performance and reduce Product sulfur content, effect of low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

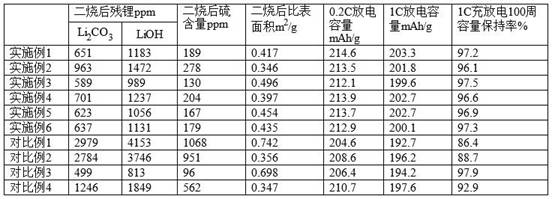

Examples

Embodiment 8

[0044] The following examples take the preparation of the 8-series nickel-rich polycrystalline ternary cathode material as an example.

[0045] The assay method of residual lithium content of the present invention is as follows:

[0046] Sample pretreatment process: Take about 10g of the ternary material sample and place it in a 250mL conical flask with a stopper, weigh it accurately, add a large magnetic stirrer in the bottle, and accurately weigh 90g of boiled distilled water in the conical flask with a stopper. Then open the rubber stopper, use N 2 Carry out gas replacement in the bottle, purging time is about 5 minutes, place the conical flask with stopper on a magnetic stirrer at room temperature and high speed and stir for 30 minutes, then let the conical flask with stopper stand for 5 minutes, and use a needle filter for rapid filtration in In a 100mL PET bottle, shake evenly and cap tightly for testing.

[0047] Titration: The first step is to accurately weigh 10g of...

Embodiment 1

[0062] A washing process for a high-nickel polycrystalline ternary positive electrode material, comprising the following steps: homogenizing the high-nickel polycrystalline ternary positive electrode material sintered for the first time with ethanol, beating and washing, and adding an ionic liquid at the same time, wherein the high-nickel polycrystalline ternary The mass ratio of positive electrode material to ethanol is 1:1, the amount of ionic liquid added is 2% of the mass of high-nickel polycrystalline ternary positive electrode material, the washing time is 40min, and the amount of grain boundary filler added is the mass of high-nickel polycrystalline ternary positive electrode material 0.1% of.

[0063] A method for preparing a high-nickel polycrystalline ternary positive electrode material, comprising the steps of:

[0064] S1. 100.00kg of nickel cobalt manganese hydroxide Ni 0.88 co 0.06 MN 0.06 (OH) 2 Put 47.64 kg of lithium hydroxide monohydrate into a high-mixer...

Embodiment 2

[0069] The difference between the washing process of the high-nickel polycrystalline ternary positive electrode material of this embodiment and Example 1 is that the mass ratio of the high-nickel polycrystalline ternary positive electrode material to ethanol is 1:0.5, and the amount of ionic liquid added is high nickel polycrystalline ternary positive electrode material. 0.5% of the mass of the cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com