Cyclic granulation method of KR desulfurizing agent

A desulfurizer and granulation technology, applied in the field of metallurgy, can solve the problems of complex process, many processing equipment, and inability to guarantee the quality and particle size of the desulfurizer, and achieve the effect of improving the degree of industrialization, reducing consumption, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

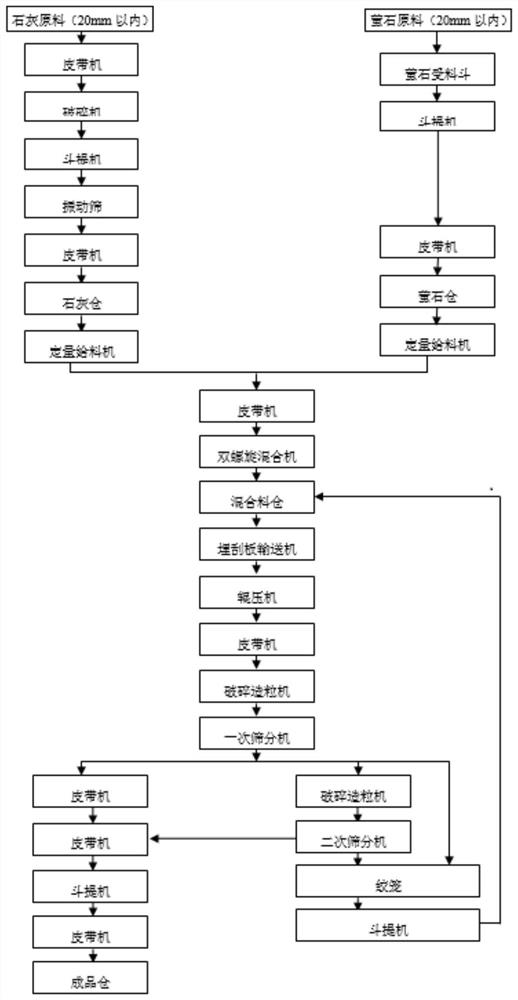

[0025] (1) Batching stage: lime and fluorite are batched in proportion, specifically: lime raw materials (within 20mm) are first crushed and then enter the bucket elevator, and then screened by vibrating sieves, qualified lime raw materials enter the lime bin, and then enter the quantitative Feeder: Fluorite raw material (within 20mm) first enters the fluorite receiving hopper, then enters the bucket elevator, then enters the fluorite bin, and finally transports it to the quantitative feeder.

[0026] (2) Mixing stage: After the lime and fluorite raw materials are distributed in proportion, they are sent to the mixer collectively; after the raw materials are mixed, they enter the mixing silo.

[0027] (3) Rolling stage: the raw materials in the mixing bin are separated by the buried scraper conveyor, and then enter the roller press for rolling.

[0028] (4) Primary granulation stage: Send all rolled flakes to the crushing granulator for centralized primary granulation.

[002...

Embodiment 2

[0032] (1) Batching stage: lime and fluorite are batched in proportion, specifically: the lime raw material goes through the belt conveyor to the crusher, then goes to the vibrating screen through the bucket elevator, and then goes to the lime bin through the belt conveyor and then is given quantitative feeding The fluorite raw material goes to the bucket elevator through the fluorite receiving hopper, and then goes to the fluorite warehouse through the belt conveyor, and finally is given to the quantitative feeder.

[0033] (2) Mixing stage: After the lime and fluorite raw materials are distributed in proportion, they are sent to the mixer through a belt conveyor; after the raw materials are mixed, they enter the mixing silo.

[0034] (3) Rolling stage: the raw materials in the mixing bin are separated by the buried scraper conveyor, and then enter the roller press for rolling, and the rolled pieces fall into the belt conveyor uniformly.

[0035] (4) Primary granulation stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com