Forming device for steel wire oblique lock catch

A forming device and oblique lock technology, which is applied in the field of steel wire lock forming devices and steel wire oblique lock forming devices, can solve the problems of high linkage requirements in equipment design, achieve good guiding and supporting functions, facilitate forming, and avoid interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

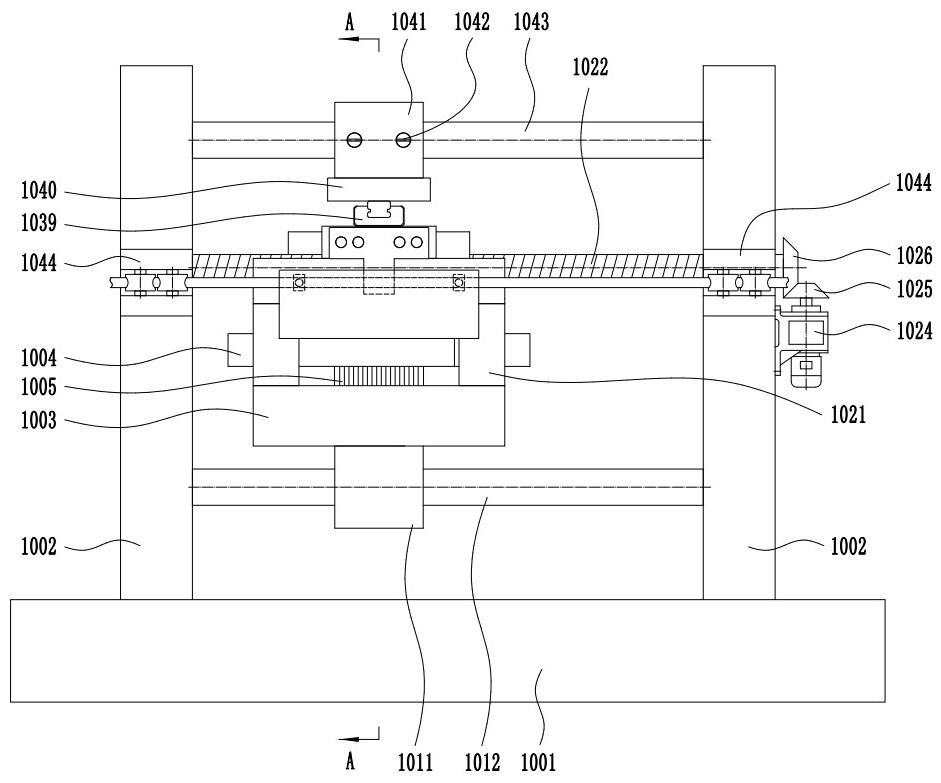

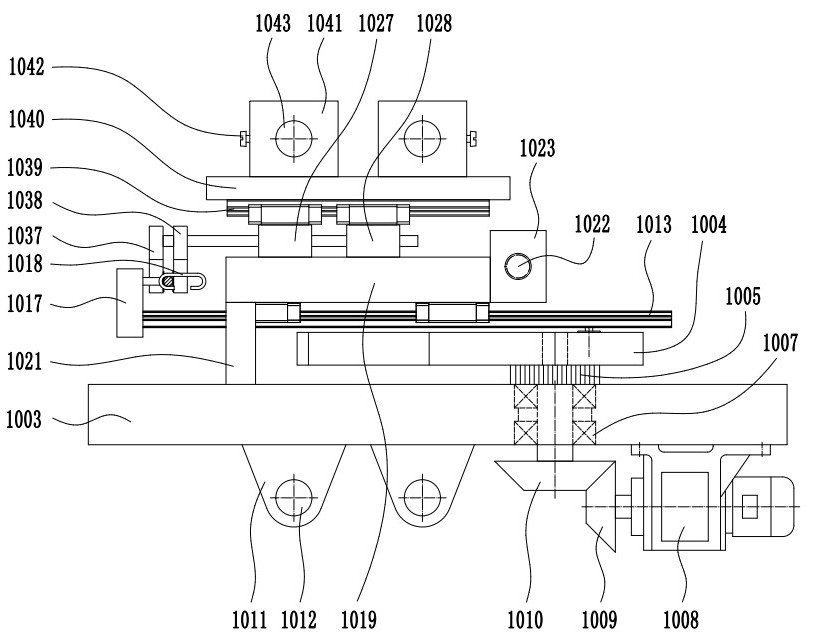

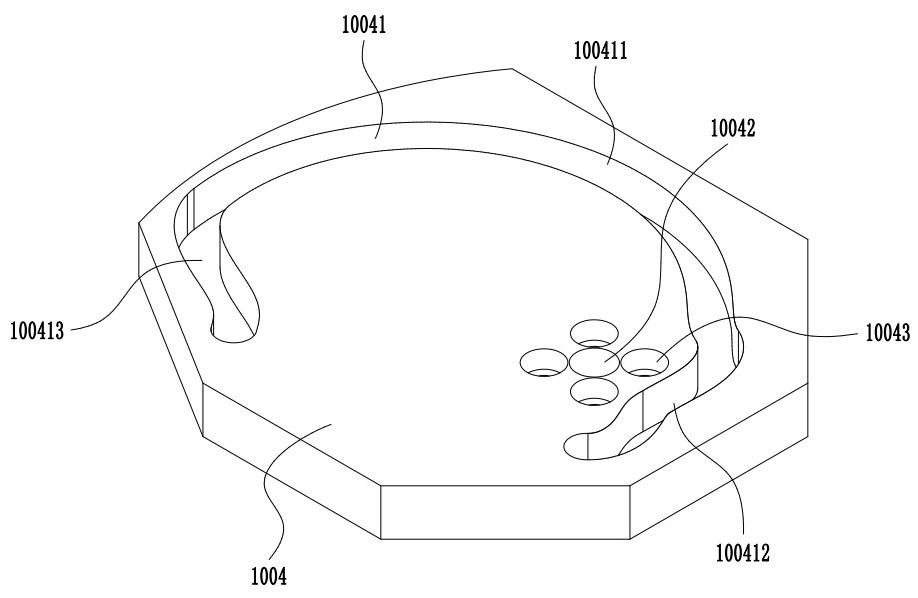

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0049] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15As shown, a steel wire oblique lock forming device includes a frame base 1001 and a frame side support plate 1002. The number of the frame side support plates 1002 is two, and the two frame side support plates 1002 are symmetrically arranged on On the frame base 1001, it also includes a forming support seat 1003, an eccentric wheel 1004, an eccentric wheel fulcrum 1005, an eccentric wheel connecting screw 1006, an eccentric wheel fulcrum bearing 1007, a first motor 1008, a first transmission bevel gear 1009, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap