Servo runner punching mechanism suitable for various punching modes and punching process

A flushing and working technology, applied in the field of semiconductor packaging, can solve the problem of high cost, achieve the effect of improving quality and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

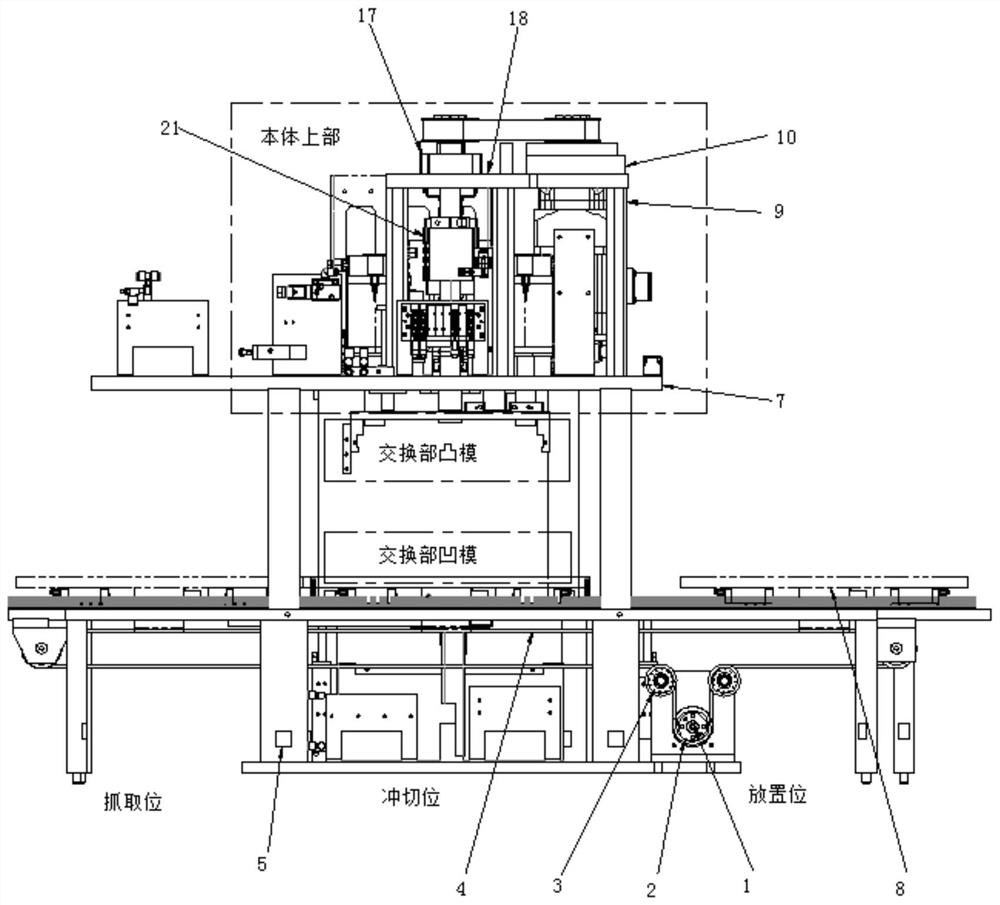

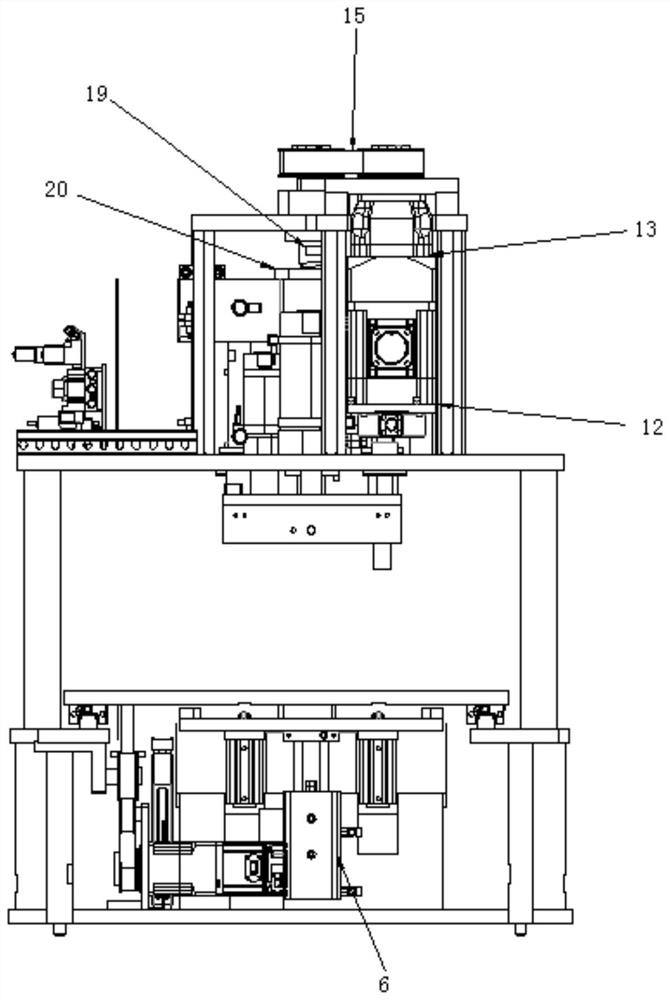

[0041] Embodiment 1, a servo punching device suitable for various punching methods, including a body part and an exchange part, the body part includes a body upper part and a body lower part, and the exchange part includes a punch and a die; the body upper part It includes a servo flushing channel mechanism, a slideway 25 is connected under the servo flushing channel mechanism, and the slideway 25 is connected to the punch. The lower part of the body includes a track, and a moving plate 8 is arranged on the track. The plate 8 is connected with a die, the body below is respectively provided with a cylinder A6 and a cylinder D28, the working end of the cylinder A6 is connected to a support block 59, and the working end of the cylinder D28 is connected with a roller 29; the punch is One of needle punching die, upper folding punch or lower folding punch, and the die is one of needle punching die, upper folding die or lower folding die. There is a servo motor A1 under the body. The...

Embodiment 2

[0046] In Embodiment 2, compared with Embodiment 1, the precise positioning mechanism adopts a structure in which the locking block A and the locking block B cooperate with the fine positioning block. The locking block A and locking block B are located on the die, and the fine positioning block is located on the punch.

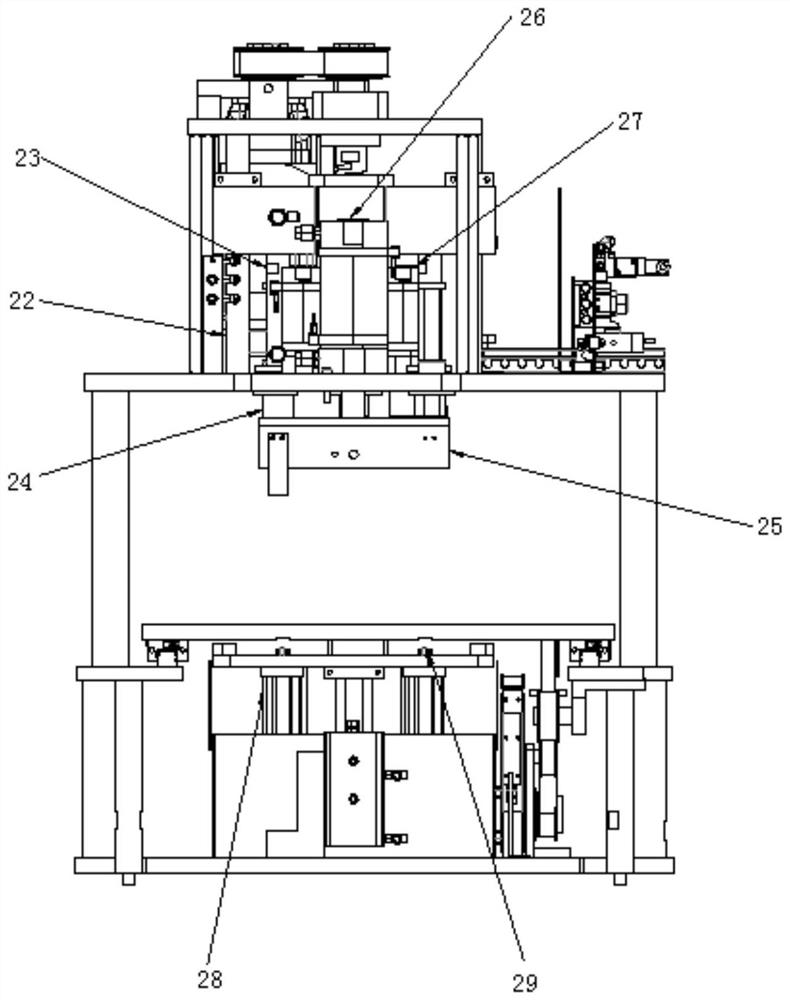

Embodiment 3

[0047] In Embodiment 3, compared with Embodiment 2, a handle 31 is fixedly attached to the bottom plate 29 of the needle punching die, and the sensor 35 is connected to the body 30 of the needle punching die through a sensor mounting plate 34 .

[0048] The punching device with this structure is used for punching, because it can take into account the punching methods of needle punching, upper folding, and lower folding. The punching process is to select the type of punch and die according to the work requirements and assemble them. Orbital movement, the lead frame enters the punching work position, the servo runner mechanism starts to work and completes punching, the servo motor A drives the orbital movement, and the lead frame leaves the punching work position; when the needle punching work is performed, the servo runner mechanism drives The needle punching punch is lowered, the servo motor B drives the moving block, and the moving block pushes the moving bottom plate to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com