Printed circuit board collecting and releasing method

A technology of printed circuit boards and rollers, which is applied in the direction of charge manipulation, conveyor objects, object stacking, etc. It can solve the problems of printed circuit board deformation and poor adaptability of suction and holding, and achieve high adaptability and low implementation cost , The effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

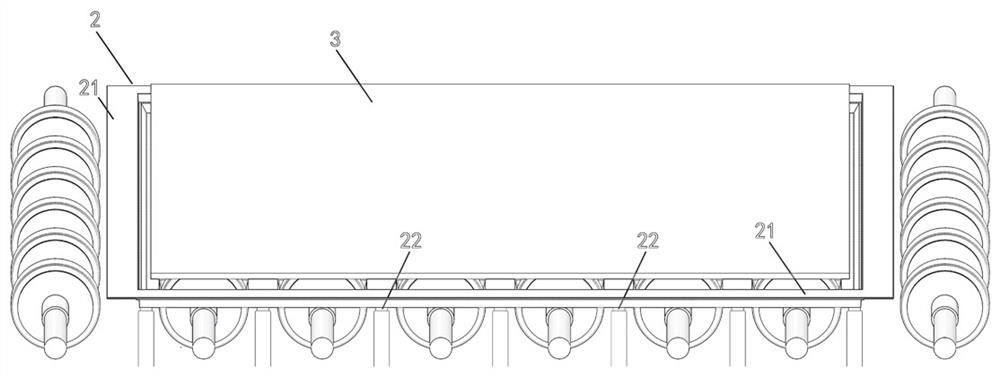

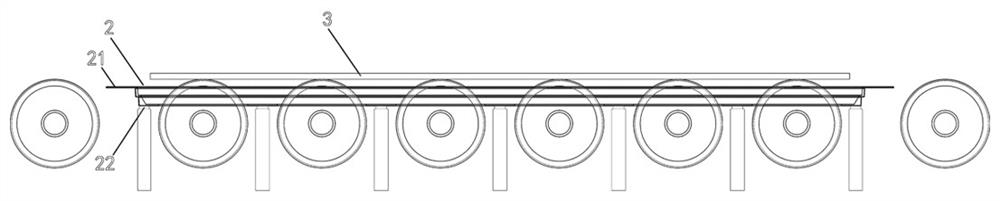

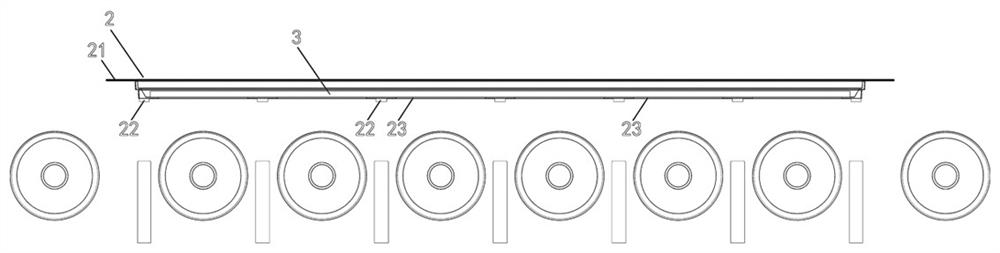

[0048] see Figure 1-3 , in an embodiment of the present invention, a printed circuit board retracting method, using a grasping device to grab and put down the TRAY above the conveying roller, so that the TRAY is combined or separated from the printed circuit board, without directly grabbing and sucking the printed circuit board. Circuit board, to realize the retraction of the non-direct contact printed circuit board.

[0049] The bottom hollow 23 of the TRAY, the position of the bottom hollow 23 corresponds to the position of the wheel of the conveying roller one by one, the TRAY can be nested into the conveying roller in this way, and sink completely below the upper surface of the conveying roller .

[0050] The top of the TRAY main body 2 is fixedly provided with a grasping edge 21 that is turned outwards, and the TRAY main body 2 can be grasped through the grasping edge 21, so that the grasping device of the automation equipment can grasp or hold the TRAY. . The grabbing ...

Embodiment 2

[0065] By combining the TRAY with the printed circuit board, first sink the empty TRAY with a hollow bottom under the upper surface of the conveying roller, and when the conveying roller above the TRAY has a printed circuit board, lift the TRAY to combine the TRAY and the printed circuit board, and then transfer this combination to the placement area to achieve the effect of closing the board.

[0066] Please refer to Figure 5 , the action to achieve the closing effect includes the following steps:

[0067] Step 1: Prepare for receiving boards. Place TRAY in the "empty TRAY station". There is no printed circuit board in the TRAY and it is in an unloaded state. Each TRAY is vertically nested with each other to form an unloaded stack.

[0068] Step 2: The grabbing device of the automation equipment moves to the "empty TRAY station".

[0069] Step 3: The grabbing device directly grabs or sucks the plane on the side of the TRAY, and grabs or sucks the empty TRAY from the empty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com