Fog dissipation cooling tower and fog dissipation filler thereof

A technology for cooling towers and defogging, applied in the field of cooling towers, can solve problems such as poor defogging and water-saving effects, unfavorable condensate capture, etc., to improve defogging and water-saving effects, reduce summer operating pressure resistance, and improve cooling effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

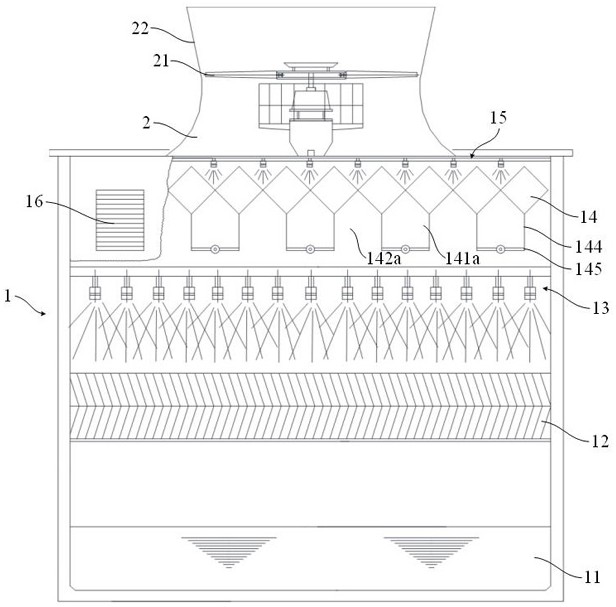

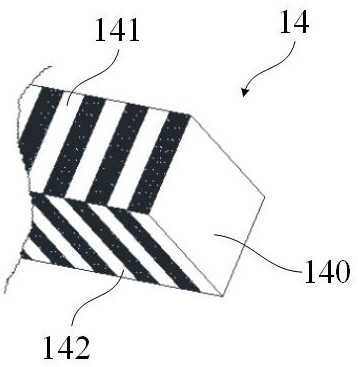

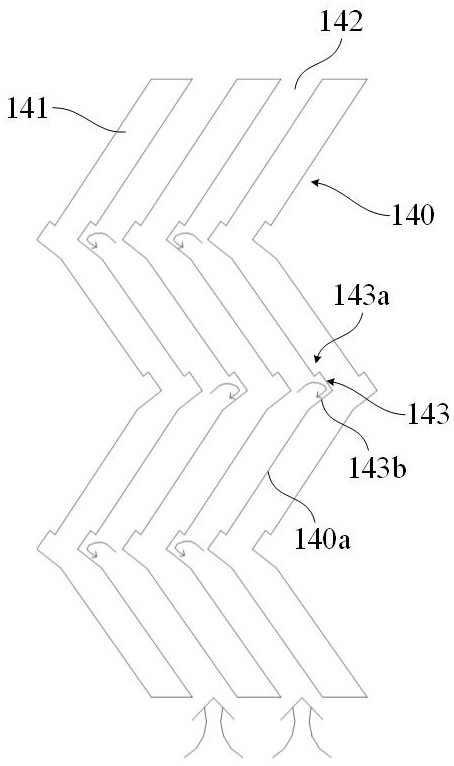

[0039] According to one or more embodiments of the present invention, with reference to Figure 1~Figure 3 As shown, the specific working process of the fog-eliminating cooling tower of the present invention is as follows (spring, autumn and winter), wherein the rotating baffle 145 is in the closed (horizontal) position, and the louvers 16 are opened.

[0040] The circulating hot water is evenly sprayed on the water-sprinkling filler 12 through the first sprayer 13, and the external dry and cold air, driven by the fan 21, enters from the air inlet (not shown in the figure) at the lower part of the tower body 1 and is sprayed. The water fill 12 flows upwards. The dry and cold air from the outside contacts with the circulating hot water sprayed by the first shower 13 above the water-spraying packing 12 in countercurrent, and transfers mass and heat on the surface of the water-spraying packing 12, and the circulating hot water is cooled and enters the bottom of the water-spraying...

Embodiment 2

[0044] In general, the anti-fog cooling tower needs to turn on the anti-fog function in spring, autumn and winter, and does not need anti-fog in summer. According to one or more embodiments of the present invention, with reference to Figure 2~Figure 4 Shown, the specific work process of the mist elimination cooling tower of the present invention in summer is as follows. Wherein the rotary shutter 145 is in the open position and the shutter 16 is closed.

[0045] The circulating hot water is evenly sprayed on the water-sprinkling filler 12 through the first sprayer 13, and the external dry and cold air, driven by the fan 21, enters from the air inlet (not shown in the figure) at the lower part of the tower body 1 and is sprayed. The water fill 12 flows upwards. The dry and cold air from the outside contacts with the circulating hot water sprayed by the first shower 13 above the water-spraying packing 12 in countercurrent, and transfers mass and heat on the surface of the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com