Intelligent control method for conveying system based on particle swarm algorithm

A particle swarm algorithm and conveying system technology, applied in the application field of multi-objective particle swarm algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

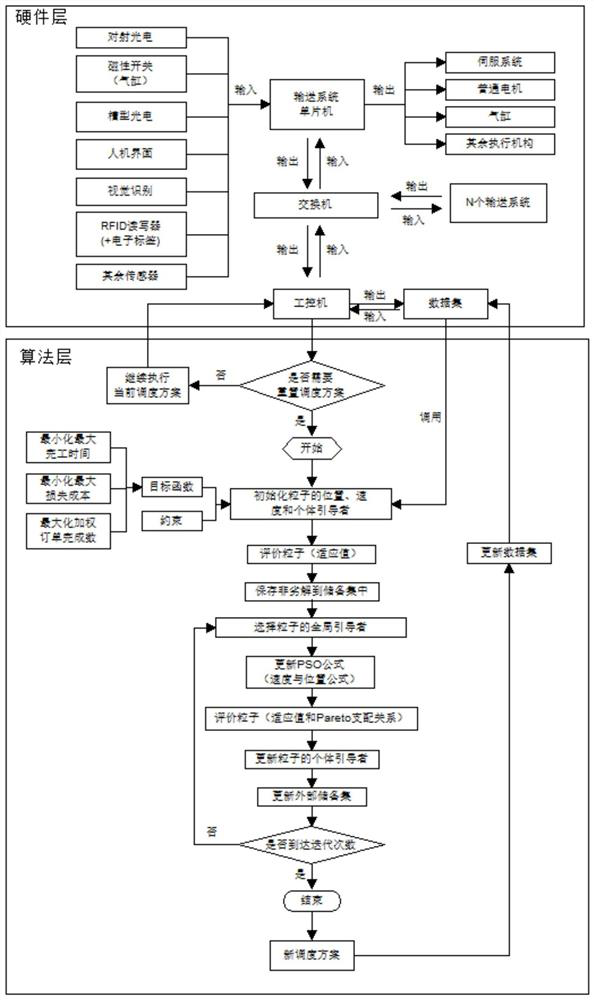

Method used

Image

Examples

Embodiment Construction

[0093] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are only specific illustrations of the present invention and should not be regarded as limiting the present invention.

[0094] Assuming that a professional R & D and production of smart home, the production of products with the characteristics of multi-variety and multi-batch intelligent scheduling needs as the background, with the expansion of enterprise scale and enterprise transformation and upgrading, there is an urgent need for highly flexible and intelligent Delivery production scheduling system.

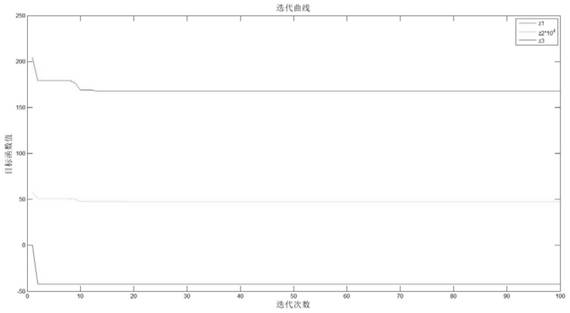

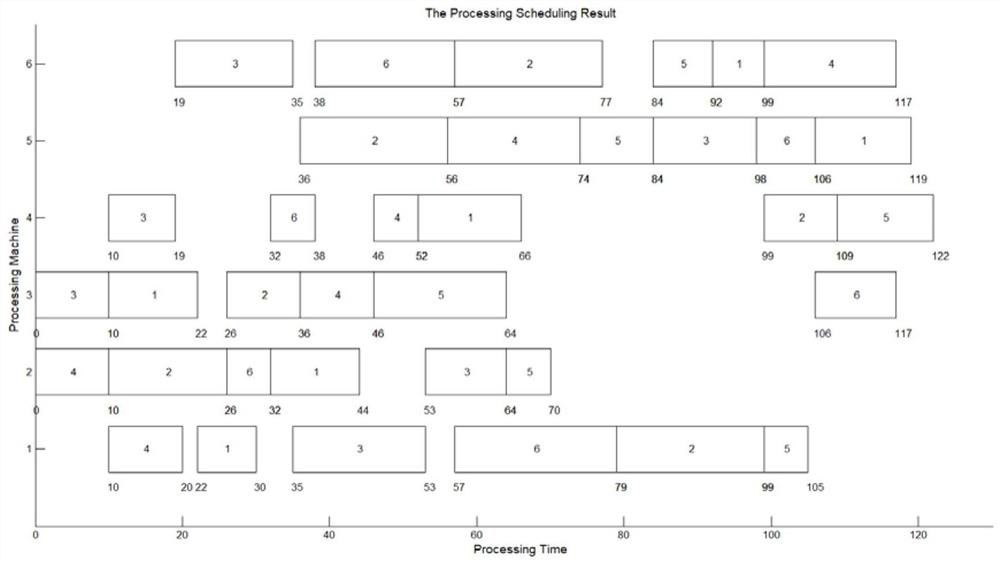

[0095] For example, the company has two products N1 and N2, where N1 is assembled by assembly J1 and assembly J2, J1 has two processing procedures K1 and K2, and J2 has one processing procedure K1. N2 is assembled from J1, J2, and J3, all of which are one processing procedure. There are 6 mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com