Cooling system and disc type motor with same

A cooling system and disc motor technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of difficulty in implementation, high processing technology, improvement, etc., to improve cooling effect, reduce thermal resistance, improve The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

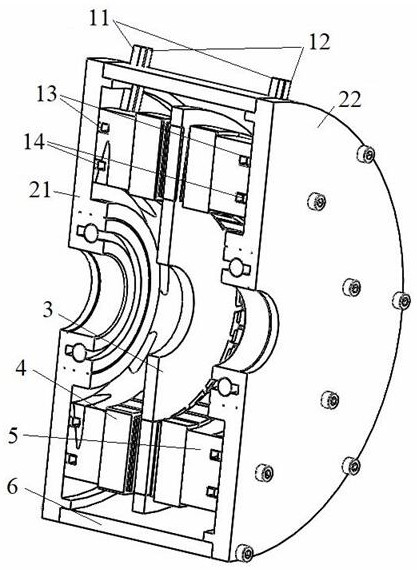

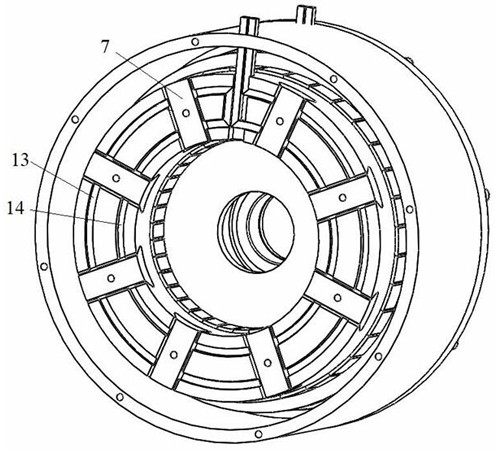

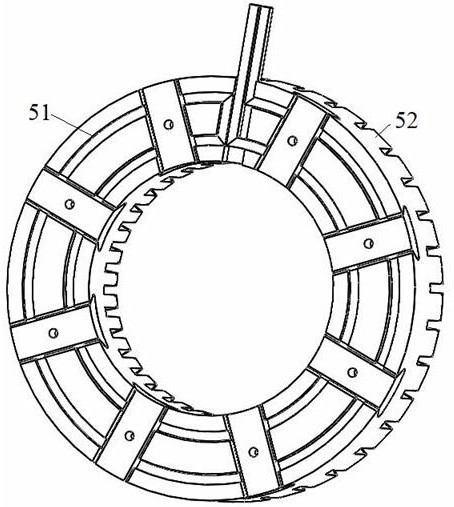

[0027] Such as Figure 1 to Figure 4 As shown, the cooling system of the present invention and the disc motor with the cooling system can obtain a disc motor with a compact structure, good cooling effect, and no obvious increase in processing difficulty without increasing the axial length of the motor. .

[0028] In this embodiment, a double-stator single-rotor amorphous alloy disc motor is used for illustration, but it is not limited thereto. Other silicon steel disc motors can also adopt the cooling method of the present invention.

[0029] The disc motor includes a casing 6, a motor front end cover 21 and a motor rear end cover 22, and a rotor disk 3, a winding 4 and a stator 5 are installed in a cavity formed by the casing 6, the motor front end cover 21 and the motor rear end cover 22. , specifically, the double-stator single-rotor amorph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com