A kind of uniform mixing structure of tobacco leaves

A uniform and mixing technology, applied in the field of tobacco, can solve the problems of poor mixing effect, affecting the progress and quality of product experiments, lack of tobacco leaf mixing devices, etc., and achieve the effects of avoiding tobacco crushing, prolonging the falling time, and improving the mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

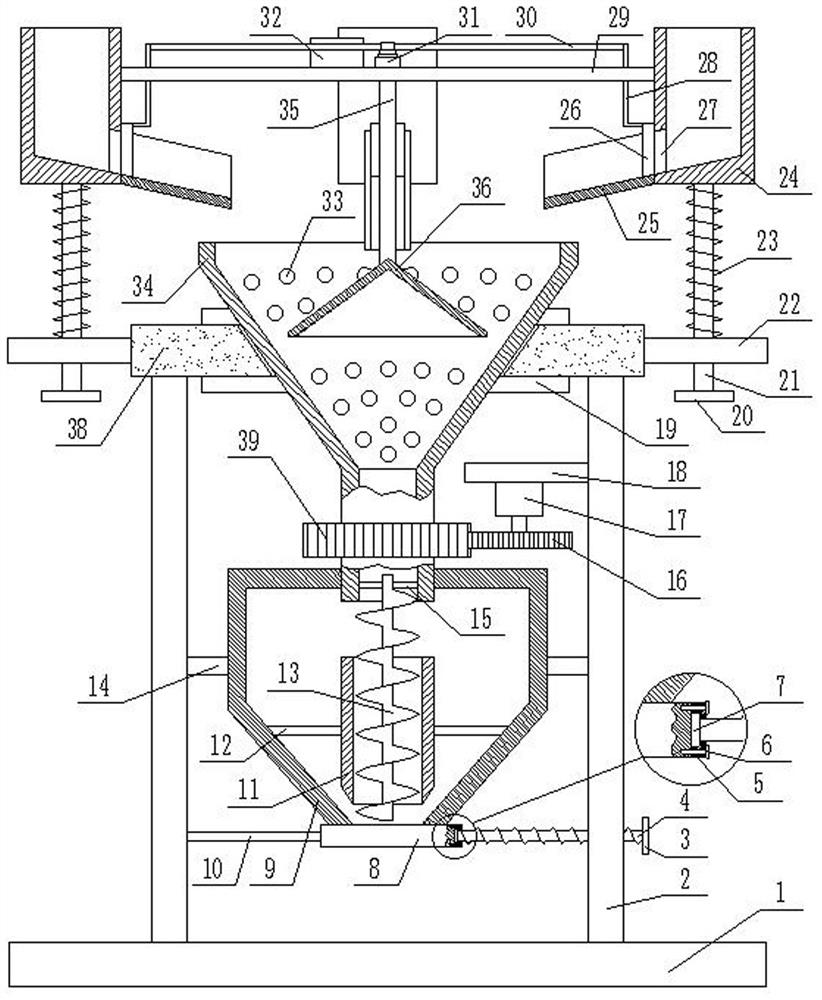

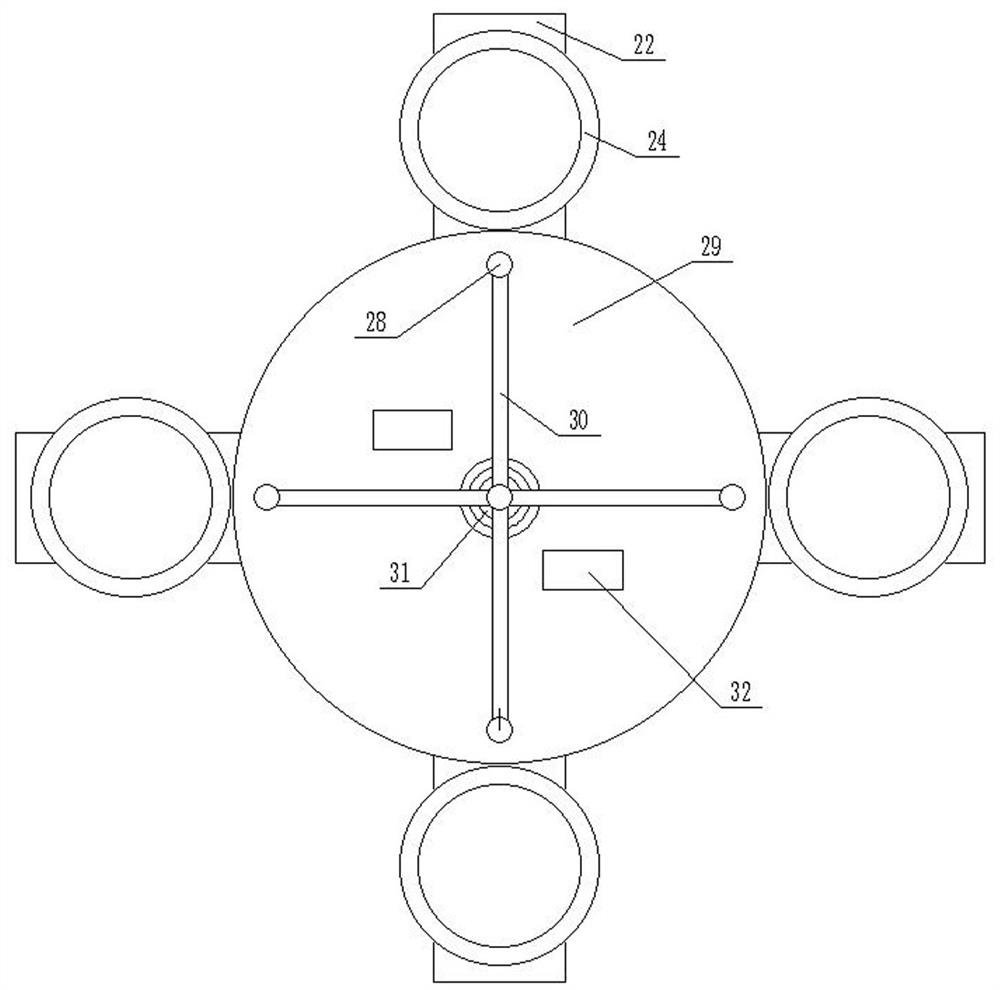

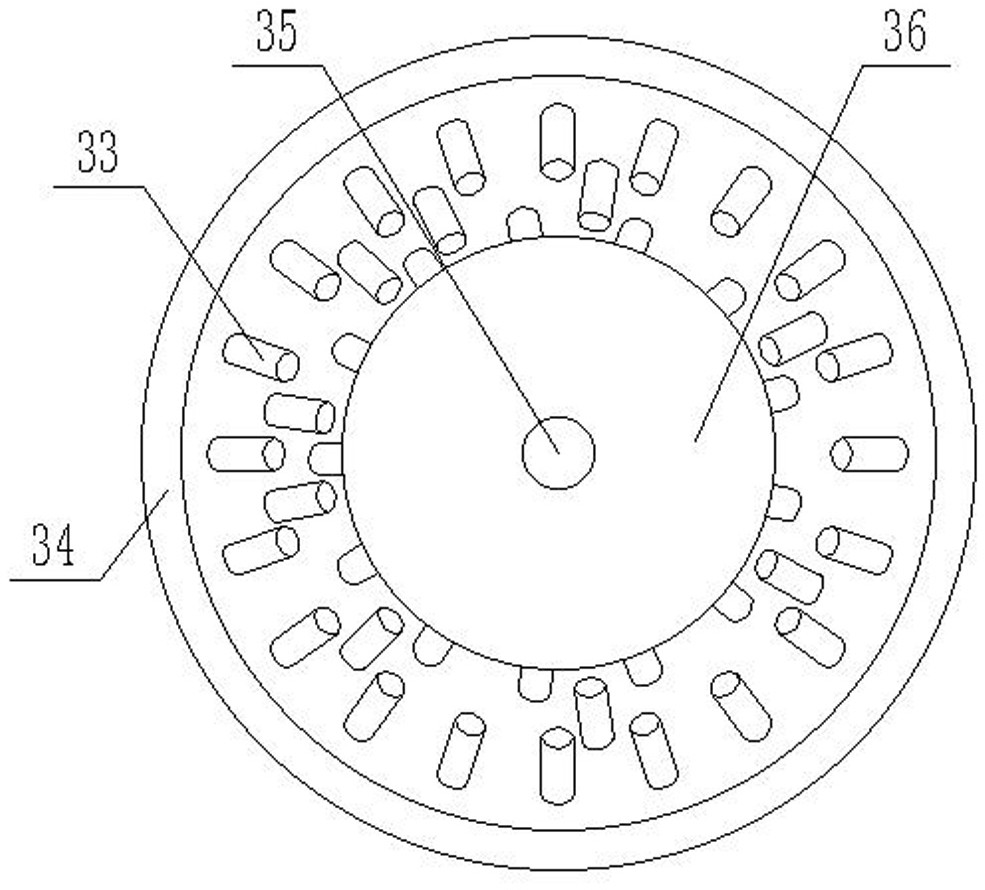

[0016] Such as Figure 1-4As shown, a uniform mixing structure of tobacco leaves includes a bottom plate 1, and the top surface of the bottom plate 1 is fixedly connected with four symmetrical vertical support rods 2, and the top surfaces of the four support rods 2 are fixed together. There is a support plate 38, the support plate 38 is perforated, and a funnel 34 is provided in the hole, the inner wall of the funnel 34 is fixedly connected with a plurality of horizontal fixed rods 33, the funnel 34 below the support plate 38 The neck of the fixed sleeve is provided with a second gear 39, and a support rod 2 at the side end of the second gear 39 is fixedly connected with a horizontal plate 18, and the bottom surface of the horizontal plate 18 is fixedly connected with a motor 17, and the motor 17 is fixedly connected to the bottom of the horizontal plate 18. The output end of 17 is fixedly connected with the first gear 16 meshed with the second gear 39; the mixing cylinder 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com