Arc welding machine communication protocol configuration method, system, device and storage medium thereof

A communication protocol and configuration method technology, applied in the field of arc welding machine communication, can solve the problems of reducing product reliability, no-load no output, current mismatch, etc., to improve product reliability, avoid blockage and errors, and improve processing bandwidth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

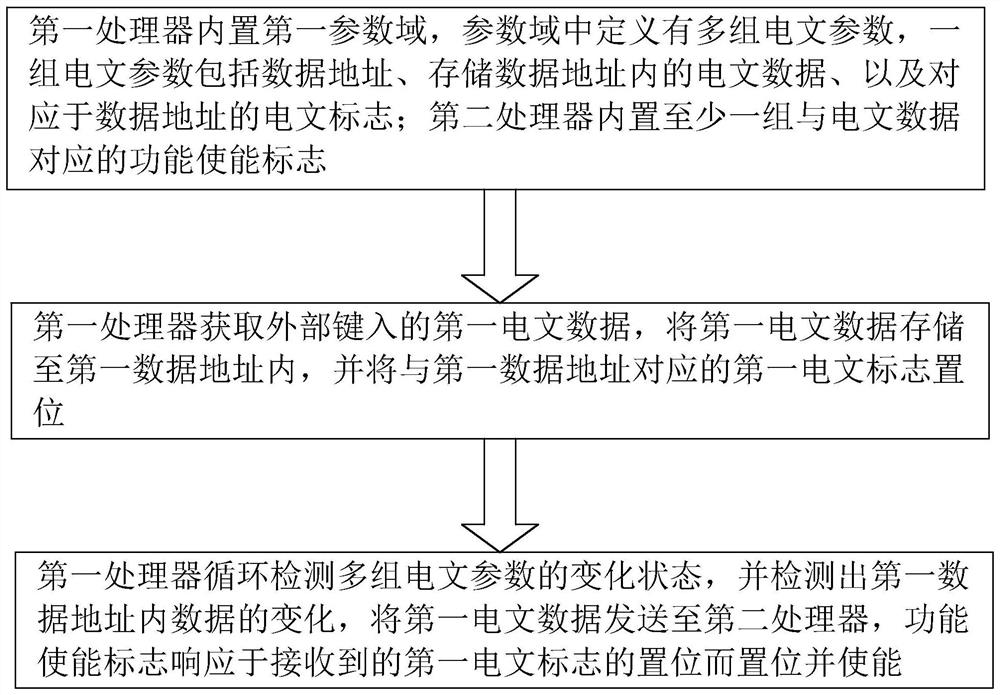

[0060] like figure 1 As shown, a communication protocol configuration method for an arc welding machine includes the following steps:

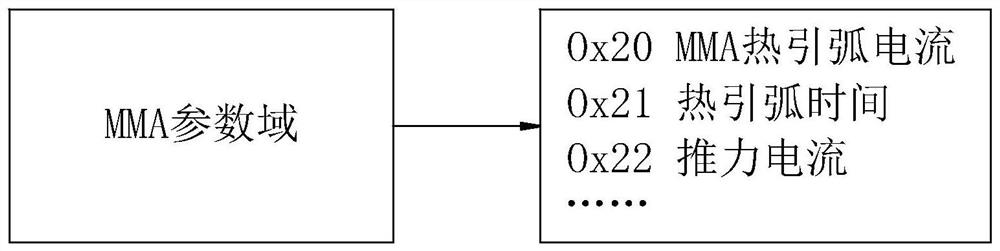

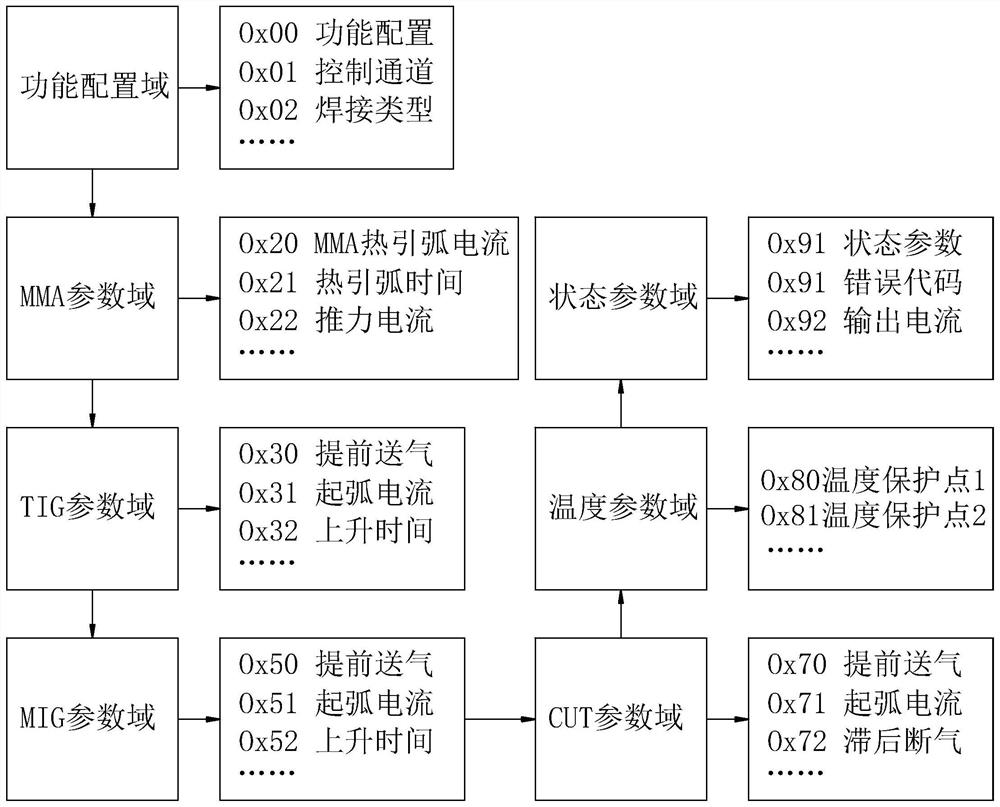

[0061] The first processor 1 has a built-in first parameter field, and the parameter field defines a plurality of groups of telegram parameters, and a group of telegram parameters includes a data address, the telegram data in the stored data address, and a telegram mark corresponding to the data address; the second processor 2 Built-in at least one set of function enable flags corresponding to the text data. The first processor 1 acquires the first telegram data entered from the outside, stores the first telegram data in the first data address, and sets the first telegram flag corresponding to the first data address. like figure 2 shown,

[0062] The first processor 1 cyclically detects the change states of multiple groups of telegram parameters, and detects changes in the data in the first data address, and sends the first telegram data t...

Embodiment 2

[0071] like Figure 4 As shown, an embodiment of the present invention provides a communication protocol configuration system for an arc welding machine. Based on a first processor 1 and a second processor 2, the first processor 1 can be a data panel, and the second processor 2 can be a data master control machine. The second processor 2 includes:

[0072] The second definition module 21 is used to build in at least one set of function enable flags corresponding to the teletext data;

[0073] The first processor 1 includes:

[0074] The first definition module 11 is used for a built-in first parameter domain, and the parameter domain defines a plurality of groups of telegram parameters, and a group of telegram parameters includes a data address, the telegram data in the stored data address, and a telegram mark corresponding to the data address;

[0075] The key-in setting module 12 is used to obtain the first telegram data entered from the outside, store the first telegram ...

Embodiment 3

[0080] An arc welding machine communication protocol configuration device includes a memory and a processor, and the memory stores a computer program capable of being loaded by the processor and executing the above-mentioned arc welding machine communication protocol configuration method. It has the characteristics of stable execution after data transmission and high product reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com