Nut projection welding process suitable for high-yield-strength plate

A welding process and high-yield technology, applied in the field of nut projection welding, can solve the problems of insufficient welding strength, virtual welding, and time-consuming arc welding process, and achieve the effects of improving welding quality and efficiency, reducing production costs, and improving welding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

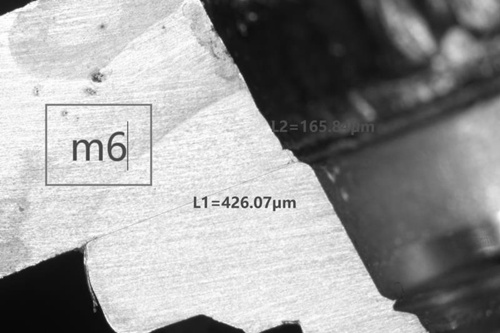

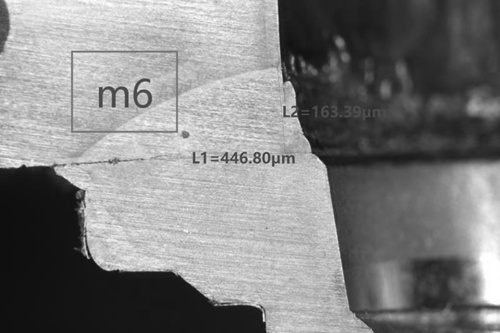

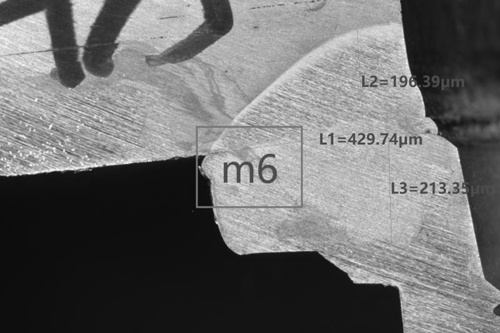

Embodiment 1

[0026] A nut projection welding process suitable for high yield strength plates, the specific steps are as follows:

[0027] Step 1: Prepare and load materials: Prepare the high yield strength plate to be welded, the nut to be welded and the welding tool, the model of the nut to be welded is M6, place the high yield strength plate to be welded on the welding tool, put For nuts to be welded, when preparing materials, reduce the cross-section of the lower electrode so that the extension of the cross-section becomes a quadrilateral circumscribed circle formed by the four welding legs of the nut, and at the same time elongate the length of the lower electrode so that the welding area of the plate is as small as possible. energy, and the heat is not easy to dissipate. The feeding process is to place the upper electrode, the nut and the lower electrode sequentially from top to bottom;

[0028] Step 2: Check the welding parameters: input the preset parameters during the welding pro...

Embodiment 2

[0034] A nut projection welding process suitable for high yield strength plates, the specific steps are as follows:

[0035] Step 1: Prepare and load materials: Prepare the high-yield strength plate to be welded, the nut to be welded and the welding tool, the model of the nut to be welded is M8, place the high yield strength plate to be welded on the welding tool, put For nuts to be welded, when preparing materials, reduce the cross-section of the lower electrode so that the extension of the cross-section becomes a quadrilateral circumscribed circle formed by the four welding legs of the nut, and at the same time elongate the length of the lower electrode so that the welding area of the plate is as small as possible. energy, and the heat is not easy to dissipate. The feeding process is to place the upper electrode, the nut and the lower electrode sequentially from top to bottom;

[0036] Step 2: Check the welding parameters: input the preset parameters during the welding pro...

Embodiment 3

[0042] A nut projection welding process suitable for high yield strength plates, the specific steps are as follows:

[0043] Step 1: Prepare and load materials: Prepare the high yield strength plate to be welded, the nut to be welded and the welding tool, the model of the nut to be welded is M10, place the high yield strength plate to be welded on the welding tool, put For nuts to be welded, when preparing materials, reduce the cross-section of the lower electrode so that the extension of the cross-section becomes a quadrilateral circumscribed circle formed by the four welding legs of the nut, and at the same time elongate the length of the lower electrode so that the welding area of the plate is as small as possible. energy, and the heat is not easy to dissipate. The feeding process is to place the upper electrode, the nut and the lower electrode sequentially from top to bottom;

[0044]Step 2: Check the welding parameters: input the preset parameters during the welding pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com